When solar labeling first surfaced around 1980, there were no set standards. Over time, the National Electrical Code (NEC) included solar systems and labeling in its standard, which started with the 1984 edition, with the most current revision being the 2017 edition.

2017 Changes to Photovoltaic (PV) Labeling Requirements

The 2017 NEC revision contains several changes that clarify solar labeling requirements. These requirements are covered in Article 690 of the NEC. Overall, labels will now provide the most relevant information to electricians and emergency responders.

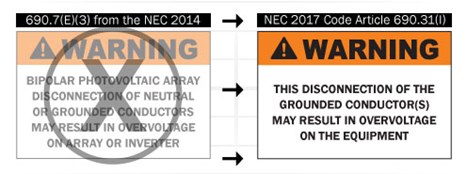

Making Bipolar PV Labels More Accurate

One change involves solidly grounded bipolar systems.

Instead of a label stating "Disconnection of Neutral or Grounded Conductors May Result in Overvoltage," the new label should state "The Disconnection of the Grounded Conductor(s) May Result in Overvoltage on the Equipment." This change can be found in Article 690.31(I) of the NEC 2017 revision.

This warning label only applies to solidly grounded systems. The design of the label must conform to NEC 2017 Article 110.21, which requires signs to follow ANSI Z535.4-2011.

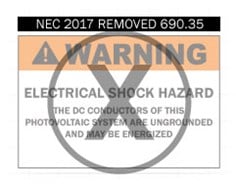

Labeling for Ungrounded Systems

Another change revolves around power labels. In an effort to simplify design requirements, NEC 2017 removed 690.35, which provided unique requirements for ungrounded systems. With its removal, solar systems are no longer required to have a label warning that the system's conductors are ungrounded.

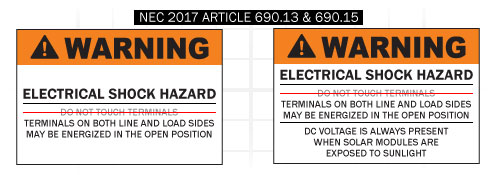

Labeling PV Disconnects

Other labeling has been simplified by removing unneeded language. The following PV disconnect labels no longer need to include "Do Not Touch Terminals." This requirement can be found in Article 690.13 and 690.15 of NEC 2017.

When the line and load terminals may be energized in the open position, installers are required to label the disconnect device with one of these signs.

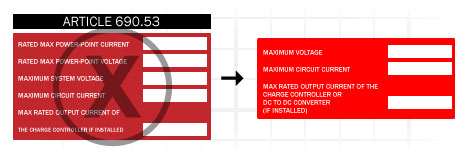

Labeling Direct-Current PV Power Information

To further simplify labeling, Article 690.53 has changed the required power information at PV disconnection points. The change reduced the number of fields by two. Now, maximum voltage, maximum circuit current, and max output current are the only required fields (as shown to the right).

This change makes the label more relevant, as it provides the exact information electricians need.

Marking Stand-Alone Systems

In an effort to make code enforcement easier, references to the authorities having jurisdiction (AHJ) and other codes have been removed from Article 690.56(A). The revision now simply requires any structure with a stand-alone PV system to have a permanent plaque or directory installed in a readily visible location. The sign must show where the system can be disconnected.

This change was made because there could be multiple AHJs, which would have their own opinion on where the directory should be located. In this case, the placement of this sign is most relevant to fire departments. Emergency responders need to quickly identify potential hazards and eliminate them, which includes locating and shutting down stand-alone solar systems. While the standard no longer requires the placement to be approved by AHJs, it's a good idea to contact the local fire department for their recommendation. Get this in writing in case the inspector questions the placement of the sign.

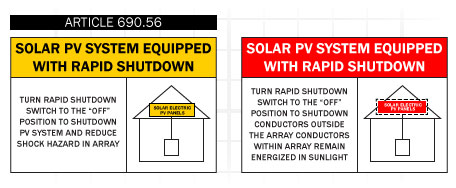

Using Rapid Shutdown Labels

Closely related to the needs of the fire department, another important change improves how a system's rapid shutdown is labeled. This standard can be found in Article 690.56(C).

The change requires a different label for two different situations, based on what the rapid shutdown system deactivates:

- The first label is required for systems that shut down the array as well as all conductors that leave the array.

- The second label is required for systems that only shut down conductors that leave the array.

Both versions of the label must include a simple diagram of a building or roof. To communicate which parts of the array shut down when the rapid shutdown switch is used, colors shall be used as follows:

- Yellow-to indicate the sections of the PV system that shut down.

- Red-to indicate sections of the PV system that do not shut down.

Buildings with both types of rapid shutdown, or a PV system that has two parts (one with a rapid shutdown switch and one without a switch), shall have a detailed plan view diagram showing the different parts, with dotted lines around areas that remain powered after the shutdown switch is used.

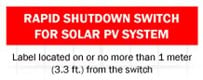

Finally, the rapid shutdown switch must now be labeled: "RAPID SHUTDOWN SWITCH FOR SOLAR PV SYSTEM." This label must be on the switch or no more than 1 meter (3.3 ft.) from the switch.

Solar Labeling Solutions

While it is one of the final installation steps, labeling is an important element for safety and compliance. Solar labels improve safety by providing essential information to firefighters, electricians, and maintenance workers. Labels enable workers to identify components, subcomponents, shutoff switches, and potential hazards before taking action.

Duralabel offers an array of DuraLabel label and sign printers that can meet your solar labeling needs. Make sure you always have the right labels for any job by printing labels, on-site, as you need them, with DuraLabel Toro. With an optional battery, Toro offers up to three hours of continuous printing to assist with labeling when out in the field.

Whether you need red reflective label stock or ANSI Z535 compliant labels, Duralabel has you covered with more than 50 specialty supplies. Get what you need for lockout/tagout, electrical safety, solar labeling, and more.

Need preprinted supplies? Duralabel Custom Labeling Service can print the labels you need, in the quantities you need, so you have the tools to finish the job.

Related Resources

GHS and HazCom Labeling for Medical Facilities

Maintaining safe medical facilities starts with effective hazard communication (HazCom). The Globally ...

Read

Label Printer Systems for Challenging Outdoor Environments

Outdoor labels serve a wide range of purposes, from identifying equipment and machinery to providing ...

Read

Choosing the Right Industrial Label Printer for Your Business Needs

In the world of industrial labeling solutions, one size certainly does not fit all. Different businesses and ...

ReadTake Action

Print Your Own Signs

Free Label Design Software

.png)