Partnerships Pull Together for Grain Bin Safety

03

February,

2023

2 MINUTE READ

When coarse grain clumps together, it can't flow out from its silo. Tragically, this is how nearly all grain entrapment incidents begin: A worker enters the confined space to break up crusted surfaces and, in seconds, a flowing column of grain pulls the person down to knee-deep levels. Any depth beyond and the situation becomes helpless. Despite progress in recent years, worker safety in the grain storage and processing industries continues to need improvement. Through education and assistance, employers can alert workers to the steps they need to take before proceeding in dangerous entry hazards and know what to do in an emergency.

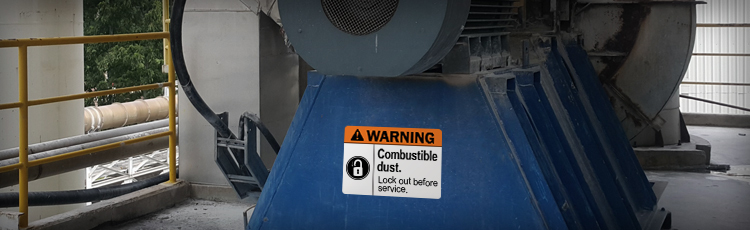

Prevention Through LO/TO

According to the Occupational Safety and Health Administration (OSHA), suffocation is a leading cause of death in grain storage bins. Entanglement with equipment is second. In 2010, 59 workers were engulfed by grain stored in bins, and 26 died, the most on record for the agriculture industry, according to Purdue University's Agriculture Economics report. Each year since, there have been about 35 grain-bin accidents, with Indiana having the highest number of incidents. OSHA says it has sent notifications to 13,000 grain-elevator operators warning employers to keep workers out of grain storage facilities without proper equipment, to properly train employees, and to turn off and lockout/tagout all equipment in use so that grain is not emptying into or out of the bin. A frequent violation, LO/TO sits at No. 5 on OSHA's violations list for 2017.

Taking safety shortcuts when handling grain can be disastrous. Identify the hazards associated with confined space work, understanding entry, and LO/TO procedures. Ensure workers are following housekeeping procedures for grain handling safety. Employers can minimize obstacles that inhibit success in production agriculture or agriculture-related occupations through visual communication and continued training and education.

Partnerships Boost Awareness

While training for grain bin rescues improves a victim's chance for survival, they still are risky and complex. Without assistance, the weight of the grain and the behavior of it in response to human movement make it extremely difficult for a worker to get out. To help increase safety awareness and rescue assistance measures, organizations such as the Ohio Farm Bureau and the Grain Handling Safety Coalition are stepping in. Ohio joins fire department rescue teams throughout the nation in gaining specialized tools and equipment to handle confined space rescues, mostly through partnership grants.

"Committee members began discussing the number of grain bins we have in the county and determined there was a need for rescue equipment," said Mandy Orahood, Ohio Farm Bureau director. Utilizing grain bin safety equipment, fire departments recently participated in the first grain-bin rescue training offered by the Ohio Fire Academy. The firefighters took turns being partially submerged in a grain bin while others practiced rescuing them.

The need for continued partnerships and awareness for grain bin safety has been a key issue for AgriSafe.org. They, along with the National Education Center for Agricultural Safety and others, are creating online resources for the agriculture industry such as speaking events, webinars, and other events. "Grain bin safety continues to be a huge threat to agriculture producers," said AgriSafe executive director Natalie Roy. "There has been a fluctuation in industry statistics. We are developing more creative partnerships between private industry and academics to demonstrate how rescues can happen and be successful. The goal is to reduce preventable grain entrapments and deaths associated with grain handling and storage."

Roy said employers should understand what it means to have a respiratory protection program and, for each task and situation, the appropriate personal protective equipment. "We want to help workers understand the hazards and put an emphasis on the right preventative and protection measures, including PPE," she said.

RELATED RESOURCES

Improve Safety Inside and Around Storage Tanks

The demand for large industrial storage tanks is increasing. Workplaces can step up safety by improving ...

Read

Safety Notes: The Importance of Safety Communication

Is your company cultivating a strong safety culture? It's important to cultivate and develop strong ...

Read

Strengthen Dust Collection System Safety

To work with dust, it must be controlled. Keep dust collection systems in top working order as well. ...

Read.png)