Strengthen Dust Collection System Safety

03

February,

2023

2 MINUTE READ

Sometimes the smallest hazards seem insignificant, but they can be deadly. This is no truer than with the hazards that come with respirable and combustible dust. When there is no strict focus on mitigating them, those tiny particles of materials such as wood or silica can wreak havoc in industrial sectors by causing severe injuries or explosions. It is also important to properly maintain dust collection systems and utilize communication to improve safety in and around them.

Dust's Harmful Effects

Dust collection systems are an integral part of operation and maintenance as they help cost-effectively mitigate hazardous dust. In any industry, it is crucial to identify and reduce worker exposures to harmful dust such as respirable crystalline silica. Like the better-known asbestos, inhaled silica can cause airway problems, cancer and other diseases, and death.

The Occupational Safety and Health Administration is increasing its action on silica dust with new enforcement and requirements in the general, maritime, and construction industries. Having a containment system is already a requirement in ensuring the health and safety of workers. Ventilation, vacuums, and water systems are just a few examples of engineering controls for silica that OSHA expects from workplaces. Today's more sophisticated dust collection systems are favored in agriculture, chemical, and other manufacturing industries because they have several benefits.

"Choosing the right industrial dust collector is an important long-term decision," according to ACT Dust Collectors. "Not only do dust collectors clear the air, but they also improve employee efficiency, increase employee retention, help ensure a safe working environment, and reduce equipment maintenance costs. This means that keeping your facility clean can be good for your bottom line."

Don't Introduce Hazards

While dust collection systems are a safety feature to mitigate dust hazards, failing to use and maintain them correctly can also introduce other hazards.

- Confined spaces: Dust collector housings may qualify as permit-required confined spaces. If workers must enter the housing for maintenance, draw up inspection and maintenance plans using OSHA's standards. Train workers on properly completing confined space work safely. Ensure workers have proper lighting and visibility. Post signs at the entrance to the confined space to warn others about the hazard.

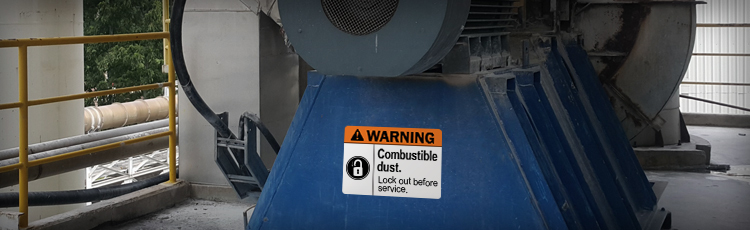

- Lockout/Tagout: Before climbing inside a dust collection silo, be sure to control the associated motors and fans using lockout/tagout. Some systems have designated lockout/tagout doors or other control points. Post lockout/tagout signs to remind workers of the steps and protocol.

- Inhalation: Dust collection systems may be intended to prevent inhalation hazards, but maintaining the systems can expose workers to those very hazards. Workers may need to wear a respirator. Remind workers about inhalation hazards and proper personal protective equipment using signs.

- Fall hazards: When equipment and access points are raised from ground level, be sure to use platforms or ladders safely and follow OSHA guidelines for fall protection. Use fall protection such as harnesses for protection from falls. Remind workers through signs and labels to use tool tethers and other safety equipment.

- Fire hazards: Where dusts are combustible, it's important to maintain fire safety as well. To thrive, a fire needs fuel, air, and a source of ignition. Mitigate any potential ignition sources such as hot surfaces, machine sparks or static buildup, and smoking or open flames. Evaluate the dust collection system for any fire hazards and control the risks accordingly.

Dust collection systems work best when workers routinely clean and maintain them, which keeps them safe and efficient. Remember to follow a job hazard analysis for regular planning to help workers understand their part in working safely in and around dust collection systems. Be sure to update those plans and communicate those changes through toolbox talks and training. Update signs and labels throughout the facility as its needs change. Include emergency planning and be sure workers understand the protocol for entrapment, including instructions and important phone numbers. Make sure the correct type of PPE is available and organized. Ensuring the reliability of dust collection systems eliminates downtime and is a cost-effective way to stay on top of hazard mitigation.

Get a reference guide to individual safety-related programs, regulatory requirements, and more in our free EHS Managers Guide.

RELATED RESOURCES

Improve Safety Inside and Around Storage Tanks

The demand for large industrial storage tanks is increasing. Workplaces can step up safety by improving ...

Read

NIOSH Digs Into Electrical Safety in Mining

To help solve mining work safety and health challenges, NIOSH continually researches best practices through ...

Read

Tips to Maximize Control Panel Safety

Never underestimate the power of electricity. While it is easy to take energy for granted, there are many ...

Read.png)