ANSI Z87.1 Eye Safety & Eye Protection Glasses

Workers in nearly every industry can benefit from eye protection. Eye safety should be a top priority to employers, especially in industries where there is the potential for hazardous materials to be present. Construction workers can protect against sawdust, laboratory workers can guard against harmful chemical splashes, and metalworkers can protect themselves from sparks, shrapnel, and other hazards.

It's important, then, to use the right eye protection for the job.

The American National Standards Institute (ANSI) aims to make that an easier and safer process by focusing on eye safety. Its standard for eye protection, ANSI Z87.1-2015, establishes the criteria for using, testing, marking, choosing, and maintaining eye protection to prevent or minimize injuries from eye hazards.

This article breaks down the standard to help employers make an informed choice when selecting and providing ANSI-compliant safety glasses. This standard can also be applied to OSHA-approved prescription safety glasses, so your workers can stay safe even if they need a prescription.

What's new in ANSI Z87.1-2015?

ANSI updated the standard most recently in 2015. The most important part of the update is organizing equipment by hazard it counteracts. This trend started with the 2010 standard. It reflects the importance of choosing the right protective gear, including safety glasses.

The update also added and changed several application-specific requirements, hazards, and equipment. It also updated equipment testing methods to reflect similar global standards.

Does OSHA Require ANSI Z87.1-2015 Compliance?

Not exactly. OSHA's eye protection standard for general industry, 29 CFR 1910.133(b)(2), only states that OSHA will accept eye protection that can be demonstrated to be at least as effective as protective eye and face protection devices that are constructed in accordance with:

- ANSI Z87.1-2010

- ANSI Z87.1-2003

- ANSI Z87.1-1989 (R-1998)

- ANSI Z87.1-1989

Given that ANSI Z87.1-2015 is demonstrated to be at least as effective as the earlier standards, items that meet the most recent standard are considered acceptable by OSHA.

Eye Protection Marking

The Z87.1-2010 and Z87.1-2015 standards have also been harmonized with face and eye protection standards used in other countries. This makes it easier to work internationally and understand eye protection requirements.

ANSI Z87.1 requires markings on eye protection that relate directly to the device's ability to defend against specific hazards. Eye protection glasses that are Z87.1-compliant are marked with "Z87."

Additional markings fall into three categories:

- Impact vs. Non-Impact

- Splash and Dust Protection

- Optical Radiation Protection

Eye Protection Categories: Impact vs. Non-Impact

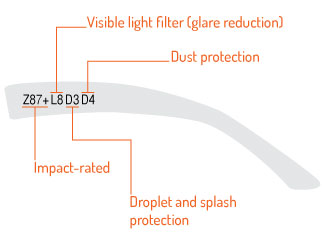

ANSI Z87.1 classifies eye protection as impact- or non-impact-rated. Impact-rated eye protection must pass certain high-mass and high-velocity tests, and provide eye protection from the side. Impact-rated eye protection will have a plus symbol (+). Impact-rated flat lenses, for instance, will be marked "Z87+."

Chemical Splash and Dust Protection

Eyewear that meets ANSI Z87.1 requirements for droplet (splash) or dust protection will be marked with a code that begins with the letter "D". For example:

- Eye protection that provides protection from droplets and splashes is marked with "D3"

- Eye protection that provides dust protection is labeled "D4"

- Eye protection that provides fine dust protection is labeled "D5"

Optical Radiation Protection

A safety glasses lenses' ability to protect against radiation is indicated by a letter designation, which is typically followed by a rating number. The markings are as follows:

- Welding Filter: "W" followed by a shade number on a scale from 1.3 to 14.

- Ultra-violet (UV) Filter: "U" followed by a number on a scale from 2 to 6.

- Infra-red (Heat) Filter: "R" followed by a number on a scale from 1.3 to 10.

- Visible Light (Glare) Filter: "L" followed by a number on a scale from 1.3 to 10.

- Clear lens: No additional marking

- Variable tint: "V"

- Special purpose: "S"

When appropriate, two additional markings will appear on eye protection:

- Eye protection designed for a smaller head size will be marked with the letter "H."

- OSHA-approved prescription safety glasses will have the manufacturer's logo.

Eye protection glasses may have several markings if it meets requirements for two or more categories. For example: Lenses marked "Z87+L8D3D4" provide impacted-rated eye protection, glare reduction, and protection against droplets and dust.

Eye Protection and Eye Safety Resources

Labeling and signage can alert employees when PPE is required, where to find it around a facility, and which eye hazards exist. DuraLabel industrial label and sign printers by Duralabel can assist in developing visual communication that keeps employees safe.

Duralabel strives to improve the health and safety of employees. Get PPE signs and labels help protect workers and encourages a hazard-free facility. Get the info you need to select and provide the right eye protection based on key requirements in ANSI Z87.1-2015 using our free chart.

Related Resources

OSHA Updates Eye and Face Protection Standards

OSHA has published a rule that updates its eye and face personal protection requirements for general industry ...

Read

OSHA Eye & Face Protection Standards: 3 Steps to Eye and Face Safety

Eye and face protection that meets OSHA standards is achievable with knowledge, proper PPE, and the right ...

Read

1910 133 Eye And Face Protection

The Center for Disease Control and Prevention reports that each day 2,000 workers have a work-related eye ...

Read.png)