5S System

Streamline workflows with the 5S system. Learn how to enhance organization, boost efficiency, and improve workplace safety to drive productivity and compliance.

Popular Resources

The 5S System Explained: From Origins to Implementation

What Is the 5S System? The 5S system is a lean manufacturing tool that improves workplace efficiency and ...

Read

5S Quick Start Guide

This quick guide helps you build an effective 5S system tailored to your environment. Whether you're new to ...

Download

What is 5S?

Do you know what 5S means? The 5S System is a lean manufacturing tool designed to improve productivity ...

Watch Now

5S System Best Practice Guide

This free 28-page guide is a must-have resource for anyone looking to improve workplace efficiency through ...

DownloadFree Guides

.webp)

Warehouse Labeling Quick Start Guide

Not sure where to start with warehouse labeling? This free guide outlines the key steps for building a safe, ...

Download

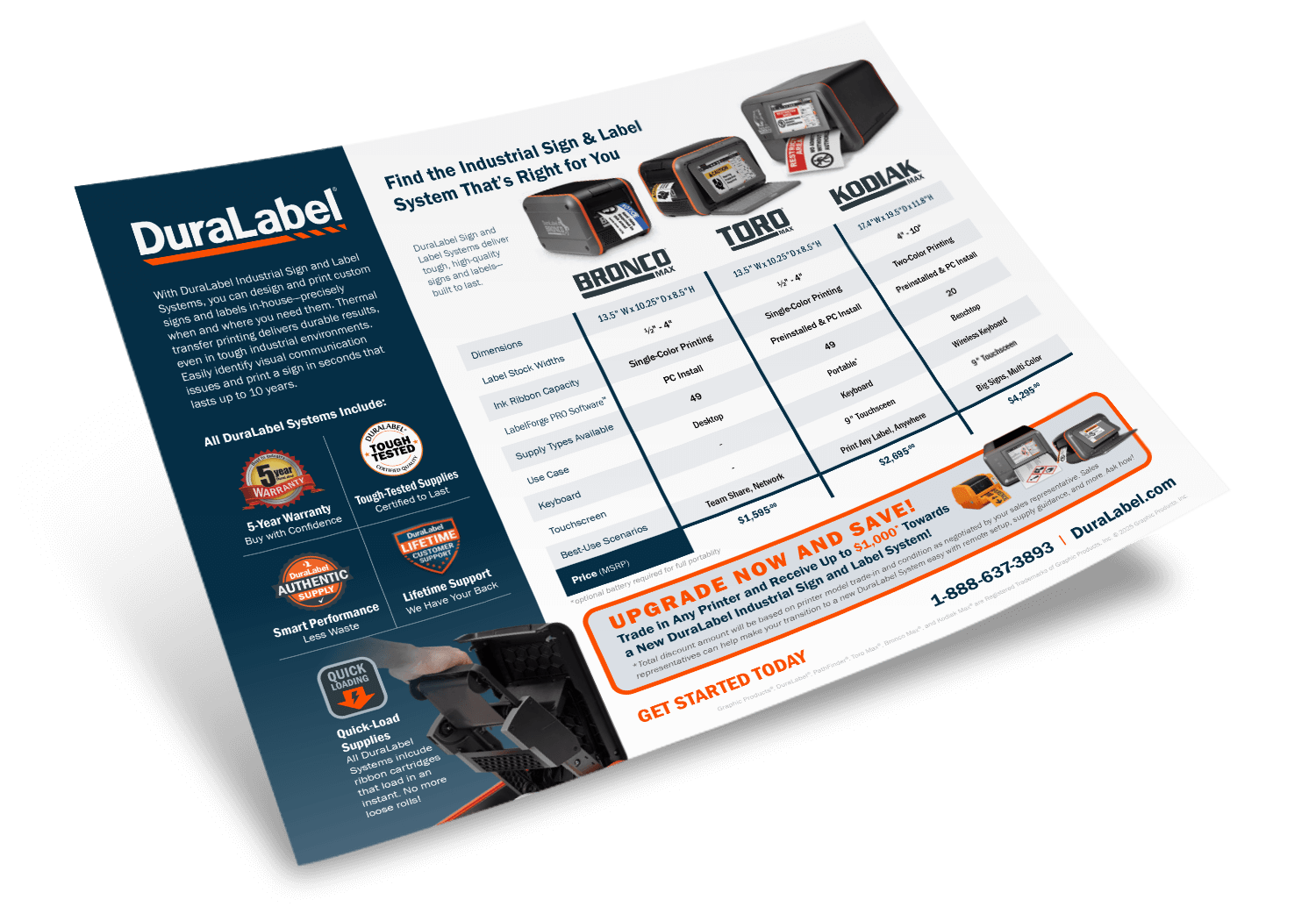

DuraLabel Industrial Sign and Label System Comparison Flyer

Not sure which DuraLabel Industrial Sign and Label System fits your needs? This flyer makes it easy to ...

Download

DuraLabel Upgrade Trade-In Flyer

Ready to upgrade your sign and label printer? This flyer explains how to trade in any printer—DuraLabel or ...

Download

Bronco Max Buyer's Guide

Discover the advantages of a reliable industrial sign and label system built for performance. The Bronco Max ...

Download

Fixed Asset Management Quick Start Guide

Effectively manage your facility's assets with this guide. Learn how to streamline operations, reduce ...

Download

Wayfinding Best Practice Guide

Enhance safety, efficiency, and organization in your facility with the Wayfinding Best Practice Guide. This ...

Download

Kaizen & PDCA Best Practice Guide

This guide offers actionable strategies for implementing Kaizen and the PDCA cycle in your facility. Learn ...

Download

Kodiak Max Buyer's Guide

The DuraLabel Kodiak Max Print System delivers unmatched ease, precision, and durability for in-house sign ...

Download

Facility Safety Communication Quick Start Guide

Elevate your aviation facility’s safety with the Facility Safety Communication Quick Start Guide, tailored to ...

Download

Toro Max Buyer's Guide

Upgrade your facility's labeling process with the DuraLabel Toro Max Print System, designed for on-site ...

Download

Barcode Color Chart

This quick reference chart is an essential resource for achieving optimal print contrast signals (PCS) for ...

Download

Visual Communication Checklist

This 36-page guide is a detailed resource designed to help you perform a thorough evaluation of your ...

Download

Barcode Labeling Quick Start Guide

This 12-page guide simplifies barcode labeling with practical tips for creating efficient systems. Learn the ...

Download

Visual Workplace Management Guide

This guide will help you identify inefficiencies and implement visual solutions to improve workplace ...

Download

5S Color Code Chart

Enhance your 5S workplace organization with this quick-reference 5S color coding guide and chart.Designed for ...

Download

Kanban Implementation Guide

This guide provides step-by-step instructions for implementing an effective Kanban system to improve ...

Download

5S System Best Practice Guide

This free 28-page guide is a must-have resource for anyone looking to improve workplace efficiency through ...

Download

5S Quick Start Guide

This quick guide helps you build an effective 5S system tailored to your environment. Whether you're new to ...

Download

Total Productive Maintenance Guide

Proactively monitoring machines and tools is key to reducing downtime and enhancing productivity. This ...

Download

6S System Quick Start Guide

Thisguide walks you through the steps to implement a lean manufacturing 6S system, which integrates safety ...

DownloadVideos

Tough-Tested Premium Vinyl Label Supplies

Order your DuraLabel Tough-Tested Supplies today: •

WATCH NOW

DuraLabel Toro Max Industrial Sign and Label System

Discover the power and versatility of the DuraLabel Toro Max Industrial Sign and Label System. Designed for ...

WATCH NOW

DuraLabel Max Line Industrial Printer Bundles & Starter Kits

Tackle compliance, safety and organization projects with DuraLabel Max Line Printer Bundles and Starter Kits. ...

WATCH NOW

LabelForge PRO: The Easy-to-Use Software for Anyone, Anywhere

Watch as our Facility Safety Manager turns workplace stress into success with the power of LabelForge PRO ...

WATCH NOW

DuraLabel Bronco Max Industrial Label Printer Feature

Meet your new safety sidekick. The DuraLabel Bronco Max is designed to streamline production of visual ...

WATCH NOWInfographics

Articles

Industrial Labeling Trends Driving Facility Compliance Forward

How Are Industrial Labeling Trends Shaping Safety and Compliance? Industrial labeling trends are shifting ...

Read

When Facilities Should Upgrade an Industrial Label Printer

When Should You Upgrade Your Industrial Label Printer? Facilities should upgrade an industrial label printer ...

Read

Learn How to Create Custom Safety Signs In-House with DuraLabel

Why Should Facilities Create Custom Safety Signs In-House? Creating clear, compliant signage

Read

Visual Management Signage That Powers Lean 5S Systems

Why Custom Signs Are Critical for Lean and 5S Implementation Lean principles prioritize clarity, consistency, ...

Read

Why Upgrade to the DuraLabel Bronco Max Industrial Sign & Label System

What Is a Bronco Max Printer Used For? The DuraLabel® Bronco® Max Industrial Sign and Label System is used to ...

Read

Essential Electrical Labeling for OSHA Electrical Safety Training

Why Is Standardized and Durable Labeling Important in Electrical Work? Standardized and durable labeling is ...

Read

Lean Manufacturing and the 5S System

What is 5S in Manufacturing? 5S is a lean manufacturing method used to eliminate waste, improve workplace ...

Read

Efficient Use of Barcoding Labels for Smarter Facility Management

With today’s technological advancements, much of the work force is searching for ways to become more ...

Read

A Practical Guide to Strategic Labeling Solutions with OSHA Labels

How Do OSHA-Compliant Labels Improve Safety and Efficiency? Occupational Safety and Health Administration ...

Read

Why Upgrade to the DuraLabel Kodiak Max Industrial Sign & Label System

How Can Upgrading to the Kodiak Max Reduce Downtime? Upgrading to the DuraLabel® Kodiak® Max Industrial Sign ...

Read

Why Upgrade to the DuraLabel Toro Max Industrial Sign and Label System

Why Would Facilities Upgrade to a Toro Max Printer? Facilities upgrade to the DuraLabel® Toro® Max Industrial ...

Read

Boosting Workplace Efficiency With 5S During Labor Shortages

How Does 5S Support OSHA Standards in Lean Workplaces? 5S supports OSHA standards by organizing tools, ...

Read

A Comprehensive Guide to Choosing the Right Industrial Label Printer

What is an Industrial Label Printer? An industrial label printer is a thermal transfer or direct thermal ...

Read

5S in Medical Facilities: Improve Safety with Visual Communication

5S in Medical Facilities Improves Safety and Efficiency Creating a robust visual communication system is ...

Read

What Is Kanban?

In the face of declining sales and profits during the 1950s, Eiji Toyoda began looking for ways to improve ...

Read

Got a Need for Speed? Here Are 5 Ways to Increase Productivity Without Sacrificing Safety

Safety is an essential element of any facility's success. The real challenge is how to maintain productivity ...

Read

4 Tips to Enhance Loading Dock Safety

There are more than 4.2 million material movers in the U.S., most of which work in transportation and ...

Read

3 Smart Ways to Improve Kanban

Sometimes, it's not smooth sailing after a company goes lean. Kanban is a workflow management method to ...

Read

Training, Communication Essential for Forklift Safety

Communication and training on a routine basis are important in maintaining forklift safety, operating a ...

Read

Lean | Not Just Grandpa's Optimization Tool

Lean has been around for decades, but it still has its place as businesses evolve and retain vitality. Big ...

Read

Utilizing Effective Websites for Manufacturing

Having an online presence when it comes to business is more than just having a website. Rebecca Hart of Drive ...

Read

Five Easy Ways to Enhance Loading Dock Safety

Warehouses are busy work environments. Keep loading dock workers moving efficiently and safety using these ...

ReadLogistics Tracking

Logistics involves managing the movement of resources. This not only includes products, but the movement and ...

Read

How to Build a 5S Implementation Team for Lean Success

What is a 5S Implementation Team? A 5S implementation team is a group of individuals empowered to make quick ...

Read

Continuous Improvement Ideas for the Workplace

Success in today's competitive market requires constant innovation and a vision focused on continuous ...

Read

Top 10 Uses for DuraLabel Industrial Label Printers

How DuraLabel Printers are Used Across 10 Key Industrial Applications DuraLabel printers are built to solve ...

Read

Planned Maintenance

Planned maintenance is a proactive approach to maintenance in which maintenance work is scheduled to take ...

Read

Kaizen Benefits: Unlocking Continuous Improvement Potential

What Are the Benefits of Kaizen in the Workplace? The benefits of Kaizen in the workplace lie in its daily, ...

Read

Product Identification

Product identification is a broad category of labeling that includes functions such as product traceability, ...

Read

Six Sigma Principles: Exploring Six Sigma, Lean, and The 5S System

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S ...

Read

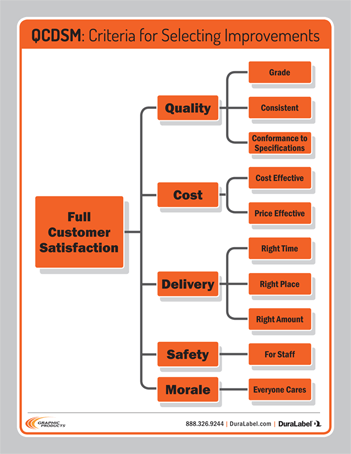

The Eight Steps to the QCDSM Process

QCDSM is a mouthful of an acronym. Once you learn its meaning and apply its principles to your business ...

Read

5S Floor Marking: Organization & Safety Fundamentals for Your Facility

What is 5S floor marking? 5S floor marking helps communicate workplace organization, improve safety, and ...

Read

Value Stream Mapping in Lean Manufacturing

What is Value Stream Mapping? Value stream mapping is a lean manufacturing technique that follows the ...

Read

The Five Whys: Root Cause Analysis Made Simple

The five whys analysis is also known as the why-why chart and root cause analysis. As these names imply, the ...

Read

Getting Started with the 5S Methodology

What Is 5S and Why Does It Matter for Visual Organization? Staying on top of operational efficiency is an ...

Read

Lean Logistics Techniques

What Are Lean Logistics Techniques? Lean logistics techniques help organizations streamline supply chain ...

Read

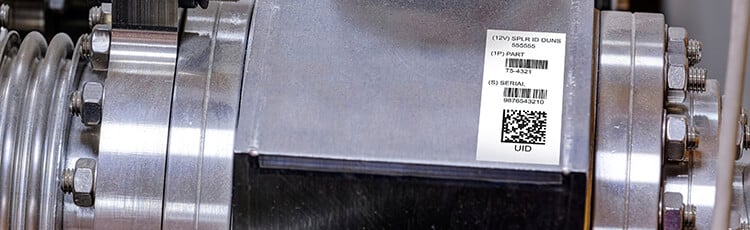

Achieve IUID Compliance with Thermal Transfer Printing

What is the Goal of the IUID System? The Item Unique Identification (IUID) or MIL-STD-130 standard was ...

Read

Creating a Visual Factory with the 5S System

What Is a Visual Factory with the 5S System? The term "visual factory" refers to an approach to lean ...

Read

Warehouse Safety With the 5S System

The 5S system offers a proven framework to improve warehouse safety, reduce clutter, and streamline workflows ...

Read

Lean Facility

Creating a Lean Facility The global market places significant pressure on businesses and other organizations ...

Read

Lean Manufacturing Process

What is the Lean Manufacturing Process? The Lean Manufacturing process is a structured

Read

TPM Implementation

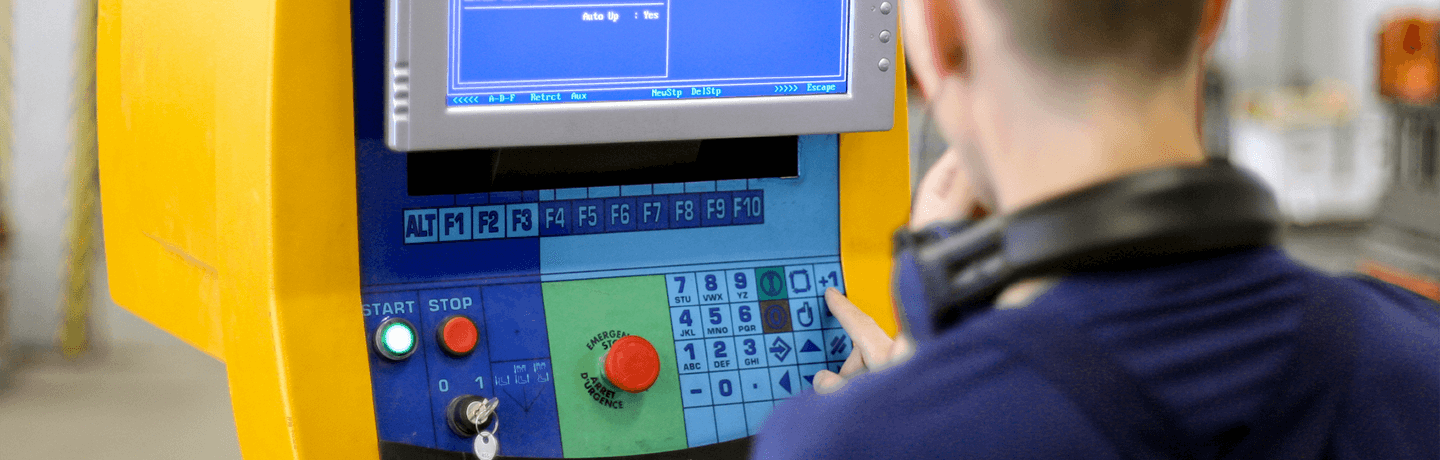

TPM Implementation Total Productive Maintenance (TPM) is a continuous improvement program that focuses on ...

Read

8D Methodology

The 8D methodology (8D=eight disciplines) was developed in Ford Motor Company in the mid-1980s to be used by ...

Read

Performance Improvement Plan

Performance is the level of achievement reached under defined conditions. Performance improvement means ...

Read

Improve Supply Chain Efficiency With Lean Strategies and The Blockchain

Today's supply chain systems are streamlining everything, from software to safety programs, for maximized ...

Read

Efficiency and Safety Improvements in Food Manufacturing

Food manufacturing is continuously improving after a huge nudge from a year of disruption. How is food ...

Read

4 Wayfinding Errors and How to Fix Them

Employees should be able to find their way safely and efficiently around the workplace. When crucial signage ...

Read

Inventory Management for Manufacturing 4.0

Industrial professionals need inventory management solutions that can handle the chaos of yesterday and the ...

Read

Lean Manufacturing Efficiency

Improving manufacturing efficiency requires eliminating waste. What is waste? Anything that is not adding ...

Read

Kaizen: Continuous Improvement Ideas for Healthcare

How Kaizen Improves Efficiency and Safety in Healthcare Settings Kaizen in healthcare empowers every staff ...

Read

Using Lean and Kaizen Theory in Manufacturing

How Kaizen and Lean Work Together to Improve Manufacturing Incorporating Kaizen in manufacturing means ...

Read

The Advantages of Lean Manufacturing: 5S, Kaizen, and TPM in Action

What Are the Advantages of Lean Manufacturing? Womack and Jones, in their book Lean Thinking, define lean ...

Read

What Is ISO 9001

The International Organization for Standardization (ISO) is the world's largest developer and publisher of ...

Read

What Is the Continuous Improvement Model?

What is Continuous Improvement? Continuous improvement is a philosophy of looking to improve products and ...

Read

Gemba Walk: A Practical Approach to Lean Process Optimization

Gemba is one of the key principles of lean manufacturing and the Toyota Production System. Gemba is roughly ...

Read

Quality Circles

The quality circle originated in Japan in the early 1960's. The objective was to give the responsibility for ...

Read

The Organizational Development Process

To understand the organizational development process, we first need to know what organizational development ...

Read

Lean Manufacturing in the Food Industry

Why the Food Industry is Going Lean The food industry is vast and serves hundreds of millions of people each ...

Read

Lean Green Manufacturing: How 5S Methods Enhance Sustainability

Manufacturing industries face pressure from both the public and private sectors, each demanding faster, ...

Read

MSHA and Others Paving New Paths for Safety

With a rampant rise in injuries from mining haulage equipment, MSHA and others are stepping up education, ...

Read

Process Cycle Efficiency (PCE)

The Process Cycle Efficiency, sometimes referred to as the "Value Added Ratio," is a measurement of the ...

Read

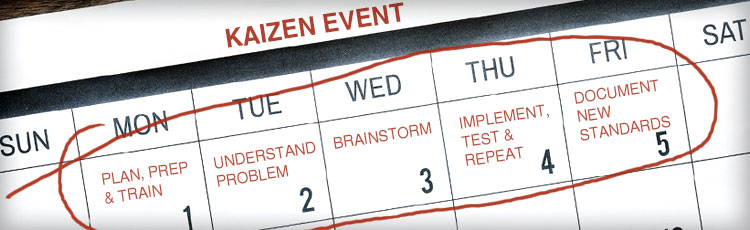

Kaizen Event: Driving Focused Continuous Improvement

What Is a Kaizen Event and How Does It Improve Lean Processes? A Kaizen event is a focused, short-term effort ...

Read

Quick Response Codes and Kanban

Quick Response codes, commonly known as QR codes, are two-dimensional barcodes that can be scanned and ...

Read

ISO 14001: Building an Effective Environmental Management System

The world's largest publisher of private business standards and requirements now offers a written program to ...

Read

2 Essential Lean Tools for Establishing New Facilities

Mitigate disruptions and build for the future using a thorough 5S plan from top to bottom. Focus on securing ...

Read

All EHS Managers Want for Christmas is ...

A list of safety supplies and other gifts that keep on giving for EHS managers. The holidays are here. ...

Read

6 Ways to Improve Office Safety in June, National Safety Month

Each year, nearly 80,000 private sector administrative workers suffer on-the-job injuries. With June named by ...

Read

What is Total Productive Maintenance (TPM)?

You're only strong as your weakest link. While trite, the phrase embodies what manufacturing plants and ...

Read

Pull System

What Is a Pull System? A pull system is a lean manufacturing strategy used to reduce waste in the production ...

Read

The Benefits of Asset Management Explained

Asset management is a system that helps you track your property and maximize the return on those assets, ...

Read

Visual Workplace and Lean Manufacturing

What Is a Visual Workplace and How Does It Support Lean? The visual workplace in Lean manufacturing uses ...

Read

NIST Certificate Calibration

There are several terms and phrases used to describe calibration standards: NIST Certificate of Calibration ...

Read

Periodic Inventory System

What is a Periodic Inventory System? A periodic inventory system is an accounting method in which the cost of ...

Read

4 Lean Secret Weapons for Next-Gen Industry

The integration of Industry 4.0 technology is fast becoming a component of lean manufacturing. Learn how ...

Read

Work Begins When the Lights Go Out

More businesses are embracing the benefits of dark manufacturing. See how a longtime business uses it and how ...

Read

House of Lean: Building the Lean Manufacturing Framework

What Is the House of Lean? The House of Lean is a useful tool that can help you understand Lean Manufacturing ...

Read

6 Steps for Improving Construction Housekeeping

Construction sites can get messy pretty quickly if proper housekeeping is not routinely enforced. Pre and ...

Read

11 Tips to Elevate Your Lean Machine

Here are 11 thoughts, words of wisdom and more to help boost and inspire Lean manufacturing. I don't know ...

Read

The 5S System Explained: From Origins to Implementation

What Is the 5S System? The 5S system is a l

Read

Floor Marking: Spring Cleaning Safety Checklist

When organizing and cleaning up work spaces this spring, consider changing up floor marking for safety, ...

Read

Lean Healthcare: Focusing on Quality and Safety

Lean Healthcare Quality and Safety Healthcare professionals have a long ...

Read

Kaizen Getting Started

There is more to implementing Kaizen than we can include on a single web page. However, the following serves ...

Read

What Is Lean Manufacturing

Lean is an efficient approach to running a process, business or organization to minimize waste, lower lead ...

Read

FOCUS PDCA: Your Guide to Systematic Process Improvement

FOCUS PDCA is a management method, developed in the healthcare industry, used to improve processes. Created ...

Read

Safety Signs for Futuristic Times

As robotic workers join the warehouse industry, it is important to have safety signs and other communication ...

Read

Heijunka Box for Lean Production Leveling

What Is a Heijunka Box and How Does It Support Lean Production? The Heijunka box is a scheduling tool used ...

Read

Tools for 5S Lean Manufacturing

The 5S system is a lean manufacturing tool that helps to clean and organize the workplace, as well as improve ...

Read

DFSS (Design For Six Sigma): A Customer Centered Process

What Is Design for Six Sigma and How Does It Improve Product Design? Design for Six Sigma (DFSS) is a ...

Read

Lean Canvas

Compared to writing a business plan, which can take several weeks or months, you can outline multiple ...

Read

FMECA

The Fundamentals of FMECA FMECA is used to evaluate reliability and identify the most critical failure modes. ...

Read

Lean on Maintenance

What is Lean Maintenance? Lean manufacturing is arguably the single greatest advance in plant efficiency ...

Read

Cross-Docking

What is Cross-Docking? At its most basic, cross-docking establishes a speedy, efficient system for unloading ...

Read

Quick Response Manufacturing

If you are familiar with lean manufacturing principles, you know that lean manufacturing is about eliminating ...

ReadSIPOC

SIPOC is an acronym for Suppliers, Inputs, Processes, Outputs, and Customers and shows how these business ...

Read

Asset Identification

For Want of a Nail Even when a small, low-value item is missing, it can result in major impact on your ...

Read

Understanding the 5 Lean Tools: Kaizen, 5S, and More

Five of the Most Helpful Lean Tools from 5S to Focus PDCA Lean manufacturing uses many lean management tools ...

Read

What Is Kaizen? - The Benefits of Kaizen Explained

What is Kaizen? Kaizen is a Japanese philosophy that means continuous improvement with Kaizen. It focuses on ...

Read

Refresh Facility Labeling Projects

An efficient workplace has labels and signs in place that work with the facility's goals. Check operational ...

Read

5S Examples in Action: The Good, the Bad, and the Successful

Can 5S Improve Efficiency and Engagement Across Industries? The 5S system is a proven method for improving ...

ReadHOW CAN WE HELP?

Labeling Project Help

DuraLabel Product Support

Get help with DuraLabel products and support with using software. Making labels, troubleshooting, or product recommendations.

Visit Product Support Center

DURALABEL PRODUCTS

Are you ready to create your own signs and labels on-site and on-demand? Shop DuraLabel printers and supplies here!

.webp)

LABELING SOFTWARE

LabelForge PRO Software allows you to create custom labels from scratch or utilize templates and modules to be compliant

FREE LABEL SAMPLES

See the quality of tough-tested DuraLabel supplies for your self with free label samples.

DURANEWS NEWSLETTER

Free monthly newsletter from DuraLabel provides industry insights and compliance news that keeps you up-to-date in labeling.

.png)

%20(1)%20(2)%20(1).webp)