Cable Labeling

Although cable labeling is not required by legal codes, the American National Standards Institute (ANSI) and the Telecommunications Industry Association (TIA) have issued a standard providing good industry practices for data centers and healthcare facilities, as well as for commercial and industrial uses in general. This standard for cable labeling is ANSI/TIA-606-B.

ANSI/TIA-606-B specifies industry standards for the labeling of cables and associated equipment. The standard covers many pieces of equipment, including the following:

- Faceplates and outlets

- Copper and fiber cable

- Cabinets, patch panels, blocks, and racks

- Cables between enclosures, racks, cabinets, and wall segments

- Building-backbone cable and termination points

- Grounding busbars

- Firestop locations

The objective is to have a clearly labeled system using a consistent and logical numbering scheme, with cables and equipment identified with easy-to-read labels that will last for the life of the cable.

Classes of Administration

The accompanying TIA-606-A standard establishes four classes of administrations, based on the size and complexity of the cabling system in the facility. The classes are:

- Class 1 - facilities that have a single Equipment Room (ER) or Telecommunications Space (TS) and typically fewer than 100 users.

- Class 2 - facilities that are within a single building, but may be served by multiple ERs within the single building. The system may be serving hundreds of users.

- Class 3 - facilities with multiple buildings on a "campus," typically serving a thousand or more users.

- Class 4 - facilities with multiple campuses or multiple locations. Typically, there will be thousands of users.

The class will impact the information that must be included on a cable label. For example, in a Class 1 facility, a compliant label would not need to specify the ER (because there is only one ER in that facility.) As the complexity of the system increases, additional elements are included as a part of the identifier on the cable labeling.

Numbering

Section 5.1.2 of TIA-606-B states that each horizontal cable should be labeled with the horizontal link identifier, within 300 mm (12 inches) of each end of the cable jacket. This allows a worker to easily follow the Information Transport System (ITS) from the data center to an individual work area, and vice versa. These labels should follow a prescribed format, which identify the specific cabinets, patch panels, and ports for both ends of the cable in question.

This type of cable labeling makes it easy to know the purpose of every cable and identify the location of both ends of the cable. Additional codes may be used for even larger facilities; for a class 3 facility, for example, a building code would be added before the cabinet location code to specify which building housed the cabinet.

A similar identification scheme is used for identifying face plates, outlets, cabinets, racks, and patch panels.

Color Coding

TIA-606-B recommends color coding, but does not require it, and the 606-B identification scheme is not dependent on color coding. However, color coding is useful for quickly identifying groups of cables, without having to read the individual identifiers on each cable.

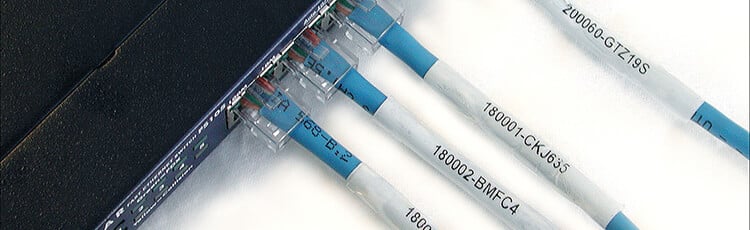

Color coded cable labeling is typically done using labeling supplies like the DuraLabel Self-Laminating Wire Wraps. With these supplies, a variety of colors are available, allowing the color coding and identifier to be combined in a single, durable cable label.

Record Keeping

Cable labeling without good record keeping can be a waste of time. Records can be take a form as simple as a spreadsheet, or a more elaborate database can be used. TIA-606-B provides a list of the recommended details that should be kept for each identifier, including information such as the cable type, color code used, outlet connector type, cable length, and the location of the outlet. Following the TIA-606-B requirements for record keeping will result in a system that can be understood by anyone in the future.

Using DuraLabel Printers

TIA-606-B also states that cable labels must be resistant to the environmental conditions they will be exposed to, and they must have a life that is at least equal to the life of the component they are identifying. This means you need to be using labeling supplies that get the job done right. With DuraLabel cable labeling supplies you'll have labels that withstand high and low temperatures, moisture, sunlight (UV), and other harsh conditions. That means that with just one cable labeling supplier, you can be assured your labels will meet all of the TIA 606-B requirements

Call 888.695.5670 today for more information about DuraLabel custom label printers and tough-tested supplies. Be sure to ask about the special DuraLabel wire and cable labeling kits. Or, download your free copy of our Wire & Cable Marking Guide below.

Related Resources

ANSI TIA 606-B Cable Labeling Standards

What is the ANSI/TIA-606-B Cable Labeling Standard? The American National Standards Institute and ...

Read

Wire Color Coding

What is Wire Color Coding? Wire color coding is a standardized system that assigns specific colors to ...

Read

Wire Marking 101

Why is Wire Marking Important in Electrical Systems? Wire marking is essential for identifying conductors, ...

Read.png)

.webp)