Cables Markers Tags

You may be wondering which type of labels you should use for identifying cables and wires.

First you need to make sure that when purchasing tags or materials for the purpose of labeling your wires you, can identify if it's just a wire wrap that is needed or a cable wrap. Not all "bundles" of wires are called cables. For example, a three wire electrical power cord, or a four wire telephone cord, may be referred to as a wire, even though that term is not technically correct. In addition, not all cables have wires in them. Fiber optic cables, for example, contain bundles of optical fibers.

Cables are labeled in a similar manner as wires, using shrink tubes or self-laminating wire wraps. However, there is a third cable marking option that may be used with large diameter cables. In addition, it would not be unusual for wire markers and cable markers to be used on the same cable. The wire markers identify individual wires within the cable, while the cable marker identifies the cable. When cables are bundled together, then cable tags are used to identify the bundles.

Cable Marking - The Three Options

The three methods for cable marking are:

- Shrink tube labels

- Self-laminating cable wraps

- Rectangular labels with over laminate

Cable Marking - Shrink Tube Labels

With DuraLabel shrink tubes you can label cables up to ? inch in diameter, and have up to eight colors of shrink tube available for color coding.

Shrink tubes are slipped over the end of unterminated cables and then shrunk to a tight, permanent fit using a heat gun. If more than eight colors are needed for color coding, combinations may be used by adding a second section of shrink tube next to the printed shrink tube cable marker.

DuraLabel shrink tubes are heat resistant and fire retardant, as well as being resistant to:

- Moisture

- Weather

- Sunlight

- Most Chemicals (extreme chemical resistant DuraLabel ribbons are available)

- Tears and abrasion

Shrink tube cable marking provides an easy-to-apply, and extremely durable cable marker. The disadvantage is that it cannot be applied to cables that have already been terminated. It may be used on CAT5 or fiber optic cables, when the shrink tube will fit over the built-in connector and still shrink to a tight fit on the cable.

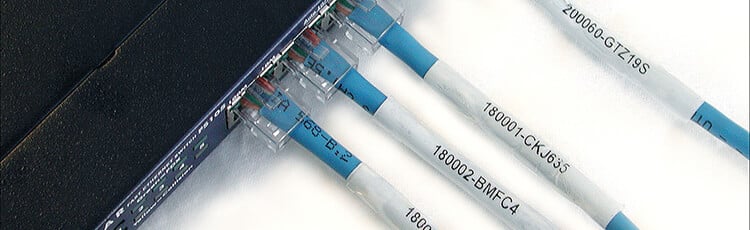

Cable Marking - Self-Laminating Cable Wraps

Self-laminating cable wraps (wire wraps) are self-adhesive labels that may be used on most cables. They provide durable cable labels that can simply be wrapped around both terminated and unterminated cables. Self-laminating cable wraps have an opaque section on which the identification information is printed. A clear tail wraps around the cable, covering and protecting the printed section where information is printed. Self-laminating wire wraps for cable marking are available in eight colors for cables up to 0.93 inches in diameter.

Self-laminating wire wraps may be applied on unterminated cables, after the cable has been terminated, or on cables that include a termination as a part of the cable, such as CAT5 and fiber optic cables.

Cable Marking - Larger Cables and Special Applications

How are cables that are one inch or larger in diameter labeled? What about labeling ribbon cables? These types of cables are labeled using "flat" rectangular cable marking labels. These are essentially conventional labels, although specialized materials may be used depending on the cable environment. These cable markers are then covered using a clear over-laminate that is applied separately by wrapping it around the cable. The over-laminate protects the label and ensures long life.

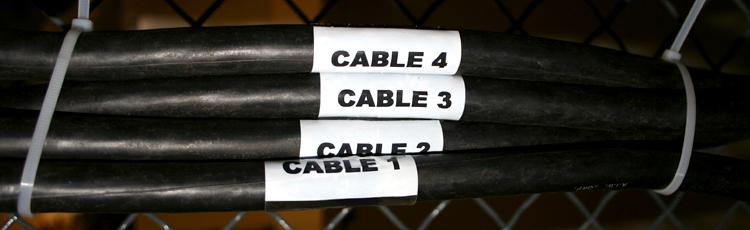

Cable Tags

Although they may be used to identify single cables, cable tags are most often used to identify bundles of cables. A cable tag is typically attached to a cable bundle using the same plastic tie-wrap that holds a bundle of cables together.

Cables may be bundled together based on their function so as to keep various types of cabling separated. In addition, bundling cables and securing them with ties helps to stabilize the cables. Cable tags then are used to identify bundles of power cables, grounding wires, a/v cables, telecommunications and data center cabling.

Cable tags should be made using a thermal transfer printer and be never hand printed. Thermal transfer printing ensures the cable tags will be legible and durable. In addition, with thermal transfer printing templates can be created to ensure standard tag formats are used, increasing the ability of the tag to clearly and effectively communicate the needed information.

Cable Tag Materials

There are two options for making cable tags. DuraTag stock provides tags that are thin and flexible, and that can be made in whatever rectangular size is needed. DuraTag stock is so tough that you can just punch a hole in the tag and attach it to the cable bundle using a tie-wrap. It's fast, simple and easy.

DuraTag cable tags are available in multiple colors and can be purchased preformatted using your custom design. You can also use blank DuraTag stock to print cable tags with whatever information you'd like, including color coding your tags.

The second option is to use rigid cable tags. Use your DuraLabel thermal transfer printer to make vinyl labels that are applied to a DuraLabel rigid plastic tag. The tag is then attached to a cable bundle using a tie-wrap.

Both the DuraTag tags and the rigid plastic tags can withstand harsh environments, including outdoor weather conditions, sunlight, moisture and exposure to oil and grease.

Cable Marking with DuraLabel

A single DuraLabel printer can handle all of your cable marking requirements, including printing shrink tubes, self-laminating cable wraps, and flat labels for larger cables. In addition, a DuraLabel printer can make conduit labels, OSHA compliant electrical safety signs, and arc flash labels. With one printer you can handle all of your electrical labeling and sign making needs.

Download your free Wire & Cable Marking Guide for expert instructions on how to mark and label your facility to improve safety below!

Related Resources

ANSI TIA 606-B Cable Labeling Standards

ANSI/TIA-606-B is a voluntary standard that establishes the labeling and record keeping standards for ...

Read

Wire Marking 101

As your workplace gets more and more wires and cables, it becomes more and more important to know which cord ...

Read

Wire Color Coding

There are many wire identification standards, and many of them rely on color codes. Not all electrical wiring ...

Read.png)