Crane Safety

Derrick, Hoist, and Crane Safety

Manufacturers, shipyard workers, and construction workers depend on industrial lifting devices to move large, heavy objects. While lifting devices like derricks, hoists, and cranes improve productivity and make work easier, they require special attention when it comes to safety.

Types of Crane Hazards

No matter the industry, employees using or working around cranes face numerous hazards. Effective crane safety depends on employers and workers understanding the hazards related to crane operation. Some of the most common accidents are caused by:

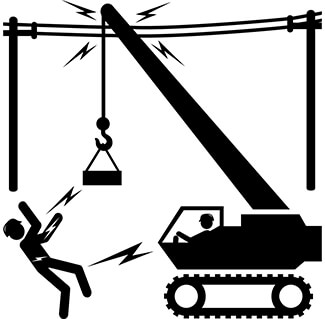

Power line contact: Cranes are large machines with a significant operating radius, making them more likely than other types of equipment to make contact with power lines. When a crane makes contact with a power line, workers touching the crane may be electrocuted. OSHA reports that a single contact can cause multiple injuries or deaths.

Overly large loads: Cranes are designed for a specific duty and load capacity. When operators exceed the rated capacity, the crane can tip over or the structure may collapse, injuring or killing nearby workers.

Improperly supporting equipment: Failing to use the proper support when lifting objects or disassembling a crane can result in structural failure or the crane falling over.

Improperly supporting equipment: Failing to use the proper support when lifting objects or disassembling a crane can result in structural failure or the crane falling over.

- Operators who fail to use outriggers when extending, lowering, or swinging the boom greatly increase the likelihood that the crane will overturn.

- Failing to properly support the boom during disassembly will cause it to collapse and possibly crush nearby workers.

Inadequate ground preparation: Cranes require a solid, stable foundation to operate safely.

- Operating a crane on soft ground may cause the crane to tip over during operation.

- Using a mobile crane on a hill may cause the crane to slide or tip over during normal operations.

Poor visibility: Crane safety depends on having good visibility. The operator must be able to recognize potential hazards before they occur.

- If the operator can't see the load, the hook may make contact with the boom tip and cause the load to fall, endangering workers.

- Workers can be caught in pinch points if the operator is unable to see them when rotating the superstructure. Usually, the worker is caught between the rotating superstructure and another stationary object. done kr du

OSHA Crane Safety Standards

OSHA has numerous crane safety standards which can be grouped into three major categories: general industry (29 CFR 1910), maritime industry (29 CFR 1917 and 1918), and construction industry (29 CFR 1926). This section lists some of the regulations relevant to the hazards covered in the previous section.

Power line contact: Overhead power lines pose a significant risk to crane operators and workers in the crane's vicinity. To help lessen the risks, employers should adhere to OSHA regulations that pertain to overhead power lines and crane safety, including:

Power line contact: Overhead power lines pose a significant risk to crane operators and workers in the crane's vicinity. To help lessen the risks, employers should adhere to OSHA regulations that pertain to overhead power lines and crane safety, including:

- 1910.180(j)

- 1910.333(c)(3)(iii)

- 1917.45(i)(5)(i)

- 1926.550(a)(15)

- 1926.1407-1411

These regulations are designed to protect workers when they are working near power lines. In these standards, OSHA established clearance requirements, operating requirements, and more.

Overly large loads: Exceeding a crane's load rating can be disastrous. In response, OSHA has created numerous regulations that can help reduce hazards and keep employees safe:

- 1910.179(b)(5)

- 1910.180(c) and 1910.180(h)(3)

- 1917.45(b) and 1917.45(g)(2)

- 1918.66(f)(1) and 1918.66(a)(3-6)

- 1926.1417(o), 1926.1433 and 1926.1436

Each industry (general, maritime, and construction) requires operators to strictly adhere to their crane's rated load capacity. Additionally, every crane must have its load capacity clearly marked and a rating chart that lists the load capacity based on operational requirements.

Improperly supporting equipment: Failing to properly support cranes can have major consequences. OSHA enforces a series of regulations that are designed to reduce risks, ensuring the work environment remains safe:

- 1910.180(h)

- 1917.45(f)

- 1918.66(a)(9)

- 1926.1404(h) and 1926.1404(q)

- 1926.1435

These regulations agree on several important points. If a load will exceed the crane's rating when used without outriggers, the operator must extend and support outriggers as the conditions require. Further, anytime a worker is working under equipment (boom, jib, and so on), it must be properly supported with blocking to prevent it from collapsing.

Inadequate ground preparation: Some of the most frequent and destructive crane accidents result from setting up cranes on unstable ground:

- 1910.180(h)(3)(xiv) and 1910.180(c)(1)(iv)

- 1926.1402(b)

Both OSHA's general industry and construction industries have specific regulations requiring employers and operators to pay particular attention to ground bearing conditions. Ground conditions must be stable and sufficient to support the crane's load.

Poor visibility: Cranes are large, powerful machines. They move heavy loads that often obstruct the operator's view. And when operators don't have good visibility, the lives of workers and other people are put at risk.

- 1910.179(c)(1)(i)

- 1917.45(f)(5)(i)

- 1918.66(a)(7) and 1918.66(c)(3)

- 1926.201(b)

- 1926.1419

These regulations are designed to keep workers safe and ensure that operators have the visibility and information they need to operate their cranes safely. In general, the regulations require:

- The cab to be free of obstructions

- Warning devices to signal when a crane begins lifting a load

- A spotter to use approved hand signals or a radio to ensure that the operator can avoid hazards

Crane Hazard Prevention

Understanding OSHA regulations and having the right communication tools are vital for ensuring safe crane operation. Duralabel offers a Crane Safety and Labeling report that can help you create a safe workplace through effective communication. Meanwhile, our line of DuraLabel printers and labeling supplies will ensure you have the right communication tools for any situation.

Cranes require specific signage to prevent potentially catastrophic accidents. Download our

Related Resources

Crane Accidents

Moving large heavy loads is crucial to today's manufacturing and construction industries. New technology ...

Read

Crane Operator Qualification Rule

OSHA and the National Commission for the Certification of Crane Operators have yet to find a resolution on ...

Read.webp)

Tips to Tame Risky Construction Activities

A recent injury report highlights contractor safety pain points. Here are several ways to mitigate these ...

Read.png)