How Contractors Use Labels and Signs to Keep Job Sites Safe

The final steps of a project are just as critical as the first. Systems are in place, connections are secure, and operations are ready to begin—but one last detail ensures long-term safety and efficiency. Clear labeling provides essential guidance for maintenance, troubleshooting, and hazard identification, keeping worksites safe and compliant long after installation is complete.

Mechanical and electrical contractors work in diverse environments, each with their own set of challenges. Workplace labeling is critical in order to minimize errors, improve efficiency, and enhance worker safety. Electrical panels, piping systems, and hazardous work zones require precise identification to meet safety regulations and keep operations running smoothly.

Many contractors still face challenges in producing durable labels that withstand the demanding conditions of industrial jobsites. Exposure to chemicals, high temperatures, and moisture can cause standard office labels to fade, peel or become unreadable, leading to safety risks and inefficient operational practices.

Workplace injuries remain a concern. In 2023, the U.S. Bureau of Labor Statistics (BLS) reported 2.6 million nonfatal injuries and illnesses in private industry. These incidents not only impacted employee well-being but also carry significant financial burdens. According to the National Safety Council (NSC), the total cost of workplace injuries in 2022 resulted in:

- $167 billion in wages, productivity loss, medical expenses, administrative expenses

- $40,000 as the average cost per medically treated workplace injury

- $91,844 per claim for injuries involving the head or central nervous system

Contractors can be held liable for employee injuries if as part of their work the safety labels does not comply with OSHA regulations and lead to unsafe work conditions. One way to rectify this is DuraLabel’s industrial labeling solutions and custom labeling services. It allows contractors to choose between on-site printing or professional printed labels tailored to their specifications. Knowing where to place, which materials to use, and when to choose custom labeling helps contractors manage facility operations more efficiently and complete projects faster while meeting Occupational Safety and Health Administration (OSHA), American National Standards Institute (ANSI), and National Fire Protection Association (NFPA) safety standards.

Where Contractors Use Custom Labels

Contractors rely on clear, reliable labels for a range of applications. These labels serve to prevent accidents, provide operational clarity, and meet regulatory requirements. Some of the most essential uses include:

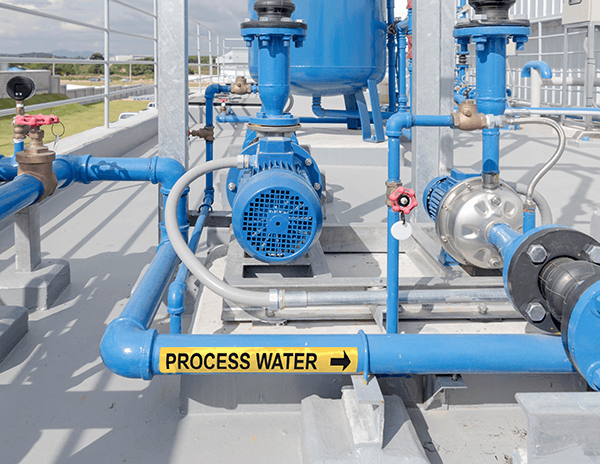

Pipe Marking for Safety and Compliance

Pipelines require clear labeling to indicate contents, flow direction, and potential hazards. OSHA and ANSI require color-coded labels for pipe markings to help workers quickly identify gases, liquids, and chemicals.

This is particularly important in industrial plants, construction sites, and manufacturing facilities, where misidentifying a pipe’s contents could lead to dangerous accidents.

Electrical Panel Labeling for Arc Flash

Electrical panels need clear arc flash warnings to alert workers to potential hazards. NFPA 70E outlines specific labeling requirements to reduce the risk of electrical injuries and fatalities. These labels display essential safety data, including shock boundaries, incident energy levels, and required personal protective equipment (PPE) for working near live electrical components.

Durable Labels for Equipment and Machinery Identification

Contractors must label control panels, circuit breakers, and heavy machinery for proper operation, maintenance, and lockout/tagout (LO/TO) compliance. Equipment identification labels help prevent misuse, improve maintenance efficiency, and provide clear instructions for operators. Additionally, OSHA's LO/TO standard (29 CFR 1910.147) requires that energy sources be properly labeled to prevent unexpected equipment startups. Failing to use durable, compliant labeling can result in costly violations and serious workplace injuries.

Work Zone and Safety Hazard Signage

Work zones require proper signage to direct workers, identify restricted areas, and communicate required PPE, fire hazards, and emergency exits. According to OSHA 1910.145, safety signs must clearly identify hazards, communicate PPE requirements, and be made of durable materials that withstand outdoor elements, chemicals, and heavy wear. These safety signs play a critical role in preventing workplace accidents and ensuring that workers understand job site risks.

Choose the Right Durable Label Material

The right label material provides lasting legibility and strength in industrial environments. Different environments require specific materials to withstand exposure to heat, moisture, and chemicals:

- Vinyl labels resist wear and tear for both indoor and outdoor applications.

- Reflective labels improve visibility in low-light conditions.

- High-temperature labels withstand extreme heat in industrial areas.

- Chemical-resistant labels hold up against exposure to solvents, acids, and industrial chemicals.

Using the correct materials ensures that labels remain legible and intact for the duration of a project.

For contractors who need on-site printing capabilities, DuraLabel offers these three industrial sign and label print systems designed to support different job site requirements:

- Toro Max: Print labels on-site. This portable, touchscreen-operated printer allows contractors to create labels on demand for immediate application.

- Kodiak Max: Handle high-volume printing. Designed for large-scale production, this printer delivers precise, long-lasting labels for demanding environments.

- Bronco Max: Balance efficiency and durability. Ideal for general industrial labeling, this printer supports a range of applications on job sites.

When to Use Custom Label Services

While on-site printing provides flexibility, some projects require a higher level of customization, large quantities, or specialty materials. DuraLabel’s custom label service allows contractors to submit their label specifications to a dedicated account manager, who creates and delivers professionally printed labels based on project needs.

Custom label services provide an efficient way for contractors to get labels designed for specific job site requirements. This process saves time while ensuring labels are durable, professionally printed, and ready for immediate use. Sending labeling specifications to a custom label service offers several advantages:

- Bulk label production – Large projects often require hundreds or thousands of labels, making it inefficient to print them in-house.

- Specialized materials – Some job site conditions require chemical-resistant, high-temperature, or reflective labels that are best produced through a professional printing service.

- Regulatory compliance assurance – Labels are produced to meet OSHA, ANSI, and NFPA standards, reducing the risk of fines and safety violations.

Contractors can work with a DuraLabel account manager to select the appropriate materials, sizes, and compliance requirements, so the labels they receive are ready for immediate use on the job site. After finalizing the label design, materials, and compliance details, the labels are printed, shipped, and ready for immediate use on the job site.

For contractors needing bulk orders or specialty labels, the process of ordering custom labels is straightforward:

- Submit labeling specifications: Provide details on size, material, design, and compliance requirements.

- Review with a dedicated account manager: Confirm the design meets project and regulatory needs.

- Receive professionally printed labels: Labels arrive ready for immediate application, reducing delays and ensuring compliance.

This service eliminates the need for in-house printing, allowing contractors to focus on their projects while ensuring their labeling requirements are met.

DuraLabel Custom Labeling Resources

Managing label production in-house for large projects can be time-consuming, especially when handling high-volume orders or specialized materials designed for harsh environments. Custom labeling services provide an efficient solution by delivering professionally printed labels that meet specific project needs.

By collaborating with a dedicated DuraLabel account manager, companies can confirm that labels are designed to meet environmental demands, including exposure to extreme temperatures, moisture, or chemicals. This approach simplifies the labeling process, allowing teams to focus on projects while ensuring essential labels arrive on-site, ready for immediate use. DuraLabel's custom sign and label service can produce materials up to 52 inches wide and 150 feet long, accommodating a wide range of project needs.

Learn more about which labeling and signage can improve project workflows and reduce confusion in your facility with DuraLabel’s free Facility Signage Handbook. This free guide will help identify the right products to boost communication and meet industry standard compliance. Give us a call today at 1-888-902-2148 and one of our safety professionals will guide you through the process.

Read Next:

How Premium Vinyl Labels Help Facilities Boost Safety and Compliance

Ensuring Lab Safety with Proper Labeling

Related Resources

Why Custom Industrial Labels Matter for Mechanical Job Sites

Mechanical job sites are fast-paced environments where precision and organization are critical. Mislabeling ...

Read

The Key to Reliable Construction Projects: Safety Signage That Works

Construction signs and labels play a crucial role in protecting workers and keeping projects on schedule. ...

Read

4 Signs Your Safety Communication Needs an Update

Safety signs and labels that are up to date, clearly worded, and in tact play a key role in achieving ...

Read.png)