Lean Healthcare: Focusing on Quality and Safety

Lean Healthcare Quality and Safety

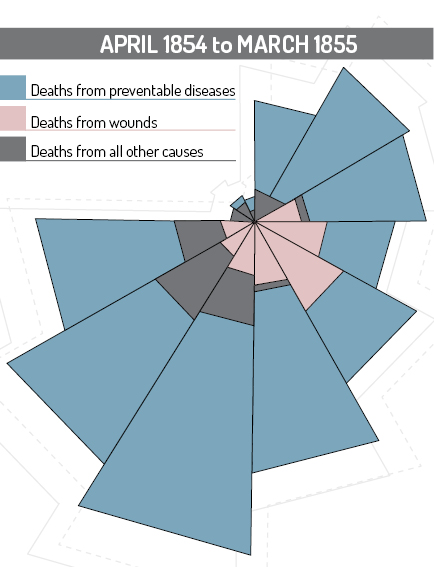

Healthcare professionals have a long history of caring for their patients and improving the quality of their services. During the Crimean War (1853-1856), British nurse Florence Nightingale realized that the mortality rate of soldiers was far too high. A visionary, statistician as well as a talented nurse, she spent months analyzing data to identify what caused the high rate of mortality. She found that hygiene and sanitation were neglected in the triage and care of the soldiers.

To get the support she needed for positive change, she created "rose diagram" that visually showed the primary causes of soldiers' mortality and convinced others of the problem. The diagram showed that infections led to the majority of deaths.

Her immediate solution was to implement hand washing and other clean practices, which reduced the mortality rate by 40%.

(Source: Lee Sidney (1912) "Nightingale Florence." Dictionary of National Biography)

Without realizing it, Nightingale practiced lean. She saw a problem, created a solution, and applied it. She focused on improving the care that her patients received. Her ultimate goal was keeping them safe and leading them to wellness.

Today, many hospitals continue to face similar challenges, and they continue to meet those challenges. The tool, however, is better developed. Today's hospitals use lean manufacturing tools to identify and solve problems. Like the methods Nightingale used, these tools focus on improving how things work, based on what patients need. Quality and safety always come first in lean healthcare.

Today's Lean Healthcare Challenges

The pressure to do more with less-consolidate functions, reduce inventory, find lower cost tools, and cut labor costs-has presented hospitals with new, yet similar challenges. To better understand these challenges, let's take a closer look at one example in particular: The Detroit Medical Center.

Instrument Hygiene

Instrument Hygiene

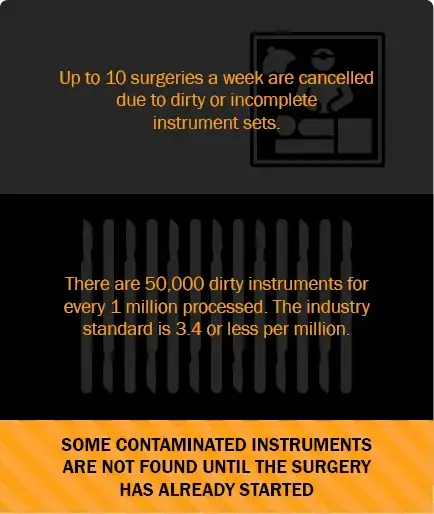

In 2010, the CEO of Detroit Medical Center (DMC) made a decision to streamline their instrument cleaning process. The result was a single processing facility to handle cleaning instruments for all five DMC hospitals. On the surface, this change makes sense. It aimed to reduce costs and simplify the overall process. However, there were some unintended consequences:

- Up to 10 surgeries a week are cancelled due to dirty or incomplete instrument sets.

- There are 50,000 dirty instruments for every 1 million processed. The industry standard is 3.4 or less per 1 million.

- Some contaminated instruments are not found until the surgery has already started.

Perhaps most concerning is the story of a 7-month-old girl who had her open-heart surgery interrupted because an instrument was clogged with blood. The surgery could not continue until the instrument was cleaned. As a result, the procedure took much longer than needed, increasing the patient's risk.

Experts say that the problems may be caused because the initial consolidation was done without understanding the potential impact on safety and quality. Additionally, the current problem has not been properly analyzed, and the root cause is not yet understood.

(Source: http://www.detroitnews.com)

While the severity of the DMC's instrument hygiene problem is uncommon, it does highlight the importance of improving processes, keeping quality and safety in the forefront. This is where lean comes into play. Lean provides a highly structured and methodical approach for identifying and solving problems, as well as improving workplace culture.

Lean Healthcare Benefits

With the constant pressure to improve the quality of care and do more with less, healthcare facilities can greatly benefit from lean tools like Kaizen and 5S. While the journey can be challenging, the benefits, like those seen by ThedaCare, outweigh them.

ThedaCare (Wisconsin)

In an effort to regain control and improve the quality of care given to patients, ThedaCare began using Kaizen to systematically find and eliminate waste. Healthcare workers were able to reduce almost 50% of wasted time from most care processes. The improvements in quality, safety, patient satisfaction, and costs are impressive.

Improved quality and safety:

- Coronary bypass mortality rates dropped to 1.4% from 4%. That's a 65% improvement.

- The average length of stay fell to 4.9 days from 6.3 days.

- Heart attack diagnosis and treatment time (door to balloon) dropped an average of 69%. Response time went from an average of 120 minutes to an average of 37 minutes.

Improved patient satisfaction:

- Patient satisfaction increased to 90% from 68%.

Reduced costs:

- Productivity increased by 12%, saving $27 million.

- The average cost per case fell to $4,911 from $7,273.

(Source: John Toussaint. Writing the New Playbook for U.S. Health Care: Lessons from Wisconsin. Health Affairs 28, no 5. 2009)

So how did they do it? ThedaCare created a Collaborative Care Wing where they fully implemented Kaizen. In this wing, they empowered nurses so they "owned" the care process. Nurses no longer have to contact a doctor before they act, reducing response time to critical issues.

Each day doctors, nurses, and other staff work together, using quality circles, to discuss procedures, identify problems, and solve problems. They typically use lean tools like FOCUS PDCA to systematically identify and eliminate problems.

The culture in the Collaborative Care Wing changed. Nurses and doctors worked more effectively with one another, communication improved, and patients' safety was always put first.

Lean Healthcare Solutions

The applications of lean healthcare are nearly limitless. In a 2015 case study, 5S was able to help streamline operations by organizing rooms and tools based on how they were used. The time it took for teams to set up for operations decreased by 37%. Doctors had more room and were able to move more efficiently because unneeded tools and supplies were removed. Before an operation began, doctors were able to tell, at-a-glance, if they had everything they needed because the room was clean and organized. Overall, it is expected that there will be a savings of $2.8 million each year for one hospital.

(Source: Journal for Healthcare Quality. September/October 2015. Volume 37, Issue 5)

Duralabel Best Practice Guide to 5S provides helpful step-by-step tips on how to create a more efficient and profitable facility through organization, cleanliness, and standardization. Streamline ER visits by:

- Reducing the number of instruments needed for surgeries

- Color coding instruments and supplies

- Creating a place for everything using floor marking and labels

Duralabel line of DuraLabel printers and supplies provides the tools needed to support your 5S program. Label equipment carts, tools, and more, improving workflow and communication throughout your facility. With a wide range of colors to choose from, you can make it easier for nurses and doctors to find the supplies they need, with facility-wide color coding. Improve facility organization and management with our free Kaizen guide below.

Related Resources

2 Essential Lean Tools for Establishing New Facilities

Mitigate disruptions and build for the future using a thorough 5S plan from top to bottom. Focus on securing ...

Read

How to Build a 5S Implementation Team for Lean Success

What is a 5S Implementation Team? A 5S implementation team is a group of individuals empowered to make quick ...

Read

Hospital Wayfinding: Visual communication for Great Patient Care

Great patient care starts with clear visual communication, and hospital wayfinding methods have been proven ...

Read.png)