OSHA Confined Space

OSHA Confined Space Safety

OSHA's regulation 29 CFR 1910.146 covers "permit-required confined spaces." This regulation provides rules for specific practices and procedures that can help to protect workers in confined spaces.

OSHA Confined Space Regulations

1910.146 requires employers to evaluate the workplace and determine if it includes any permit-required confined spaces. If the workplace contains permit spaces, the employer must inform exposed employees by posting signs warning about the existence, location, and hazards of the permit spaces.

1910.146 gives an example of the wording that could be used to mark a permit-required confined space: "DANGER - PERMIT-REQUIRED CONFINED SPACE, DO NOT ENTER." In addition to this or similar text, the sign should follow the ANSI Z535 standards for a danger sign.

What is a Permit-Required Confined Space?

The terms "permit-required confined space" and "permit space" refer to the same thing: an enclosed area that meets OSHA's definition of a "confined space" with health or safety hazards.

OSHA defines a confined space as having all three of these characteristics:

- Large enough for a person to enter and perform work

- Not designed for continuous occupancy

- Having a restricted means of entry/exit

Confined spaces may include boilers, underground vaults, tanks, silos, pipes, storage bins, pits, industrial trash compactors, hoppers, and diked areas.

To be classified as a permit-required confined space, the space needs one or more of these additional characteristics:

- Contains, or has the potential to contain, a hazardous atmosphere.

- Contains a material that could engulf a person.

- Internally configured such that an person could be trapped or asphyxiated. For example, it may have a floor that slopes downward and tapers to a smaller cross section.

- Has any other recognized serious hazard to safety or health.

If an employer determines that their employees may need to enter a permit-required confined space, OSHA requires that they prepare a written confined space permit program. The program must be made available to employees and their representatives.

If employees are not expected to enter the permit spaces, OSHA requires the employer to prevent employees from entering the spaces.

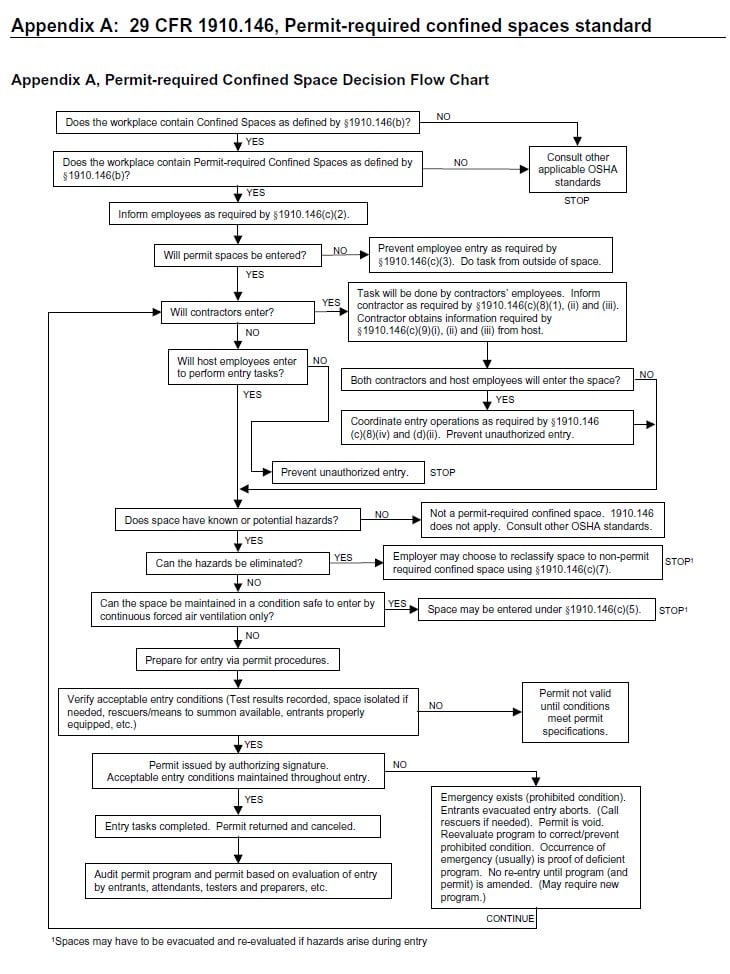

Appendix A of 1910.146 provides a decision flow chart for confined spaces. This tool helps determine when a confined space requires a permit.

Types of Confined Space Hazards

Occupational Safety and Health (the Canadian version of OSHA) estimates that rescuers account for 60% of confined space fatalities. Without the proper tools and training, confined spaces are often more dangerous than other workspaces.

Hazards in confined spaces can include:

- Poor air quality The air may not have enough oxygen or may contain toxic gases, causing workers to lose consciousness or become ill.

- Chemical exposure Workers may be exposed to chemicals through skin contact, inhalation, or ingestion, causing them to become ill or otherwise incapacitated.

- Fires Confined spaces often contain gases or oxygen-enriched atmospheres, which can ignite with the slightest spark.

- Noise Sound is usually amplified in confined spaces and can easily damage a worker's hearing, making it more difficult to recognize other potential hazards.

- Slips and falls Manholes, tanks, and silos generally have little built-in fall protection, making it easier for workers to lose their balance and fall.

- Extreme heat Many confined spaces amplify temperatures. These spaces may become overly hot and cause workers to suffer from heat stroke or dehydration.

- Unstable material Silos, vats, and other spaces are not always designed with safety in mind. These spaces may contain unstable material, which can bury workers if it unexpectedly shifts.

- Barrier failure Some confined spaces have barriers designed to hold back water or solid material when workers perform maintenance. These barriers may fail and cause workers to suffocate or drown.

- Uncontrolled energy Mechanical, electrical, hydraulic, pneumatic, and other sources of energy are often present in confined spaces. If these energy sources are not properly isolated and locked out, they may seriously injure workers.

Written Confined Space Permit Program

If entry into a permit-required confined space is allowed, the employer must create and implement a written program for that confined space. OSHA requires the written program to:

- Describe measures taken to prevent unauthorized entry

- Identify and evaluate any hazards in the space

- Require testing the atmospheric conditions before anyone enters the confined space, and monitor the space during entry. Test for oxygen, combustible gases or vapors, and toxic gases or vapors.

- Require the necessary steps to eliminate or control the hazards, such that entry and work in the confined space can be accomplished safely.

- Identify the specific tasks needed to complete the work in the confined space

- Require employees to use the appropriate personal protective equipment (PPE) and other safety equipment. (This equipment must be provided and maintained by the employer at no cost to the employee.)

- Require at least one attendant to be stationed outside the permit space for the duration of the entry.

- When employees of more than one employer are working in the permit space, coordinate their entry operations.

- Describe procedures for summoning rescue and emergency services, and for preventing unauthorized people from attempting rescue.

- Include procedures for the preparation, issue, use, and cancellation of entry permits.

- Establish the procedures to cover a situation in which an attendant monitoring multiple confined spaces must respond to an emergency in one or more of those spaces.

Once the program has been created, it must be reviewed at least annually and revised as necessary.

Entry Permits for Confined Spaces

A confined space entry permit, signed by the entry supervisor, must be completed before work is done in that space. The permit must be available to the entrants before they enter the space, such as by posting them at all entrances to the space. Signs and labels should be used to clearly identify permit-required confined spaces and remind workers to obtain an entry permit.

The permit must verify that the pre-entry preparations outlined in 1910.146 have been completed. The duration of entry permit must not exceed the time required to complete the work assignment.

Confined Space Permit Contents

Entry permits must include the following information:

- Name of the permit-required confined space

- Reason for the entry

- Date and authorized duration of the entry

- Identities of authorized entrant(s), and names of the attendants

- Name and signature of the supervisor who has authorized entry

- Identification of all known hazards in the space

- Measures to be taken to eliminate or control the hazards

- Acceptable entry conditions

- Results of initial and periodic tests, along with the initials or name of the tester, and the times of the tests

- Identification of rescue and emergency services, and the means to summon those services (such as the equipment to be used or phone numbers to be called).

- Communication procedures and the equipment required to maintain contact during entry

- Identification of any special equipment and procedures that are needed, such as PPE or alarm systems

- Any additional required permits, such as those needed for energized electrical work that have been issued to authorize work in the permit space

- Any additional information needed to ensure employee safety

Canceling Entry Permits

The entry supervisor must cancel the permit-required confined space entry permits when the work assignment is completed, or when new conditions are detected. Any new conditions must be noted on the canceled permit and used to revise the permit-required confined space program. OSHA requires that all canceled entry permits are kept on file for at least one year.

Worker Training for Confined Spaces

The employer must provide all necessary training for every worker who is required to enter a permit-required confined space, before those workers enter the confined space. In addition, the employer must ensure that the employees have learned and remember what was taught in the training, and that they know whatever is necessary to safely perform their duties. Additional training is required when:

- Job duties change

- A change occurs in the permit space program, or the operation presents any new hazard

- An employee's job performance does not meet standards for permit-required confined space entry

Rescue team members must be trained in CPR and first aid. Employers must certify that this training has been provided.

A written record must be kept of completed permit-required confined space training. This record must be available to employees and their authorized representatives. The record must include the employee's name, the trainer's signature or initials, and dates of the training.

OSHA Confined Spaces Communication Solutions

Duralabel has a comprehensive range of lockout/tagout and confined space safety signs that can help keep workers safe. Our OSHA resource center contains best practices and in-depth guides that can help you comply with key standards and keep employees safe.

Download your free OSHA Confined Spaces Guide Below

Related Resources

1910 136 Foot Protection

According to the Bureau of Labor Statistics, most of the workers in selected occupations who suffered impact ...

Read

Understanding OSHA's 1910 120 (HAZWOPER) Requirements

OSHA is not involved in regulating hazardous waste. However, they are concerned about the safety of workers ...

Read

1910 138 Hand Protection

Examples of injuries to your employees' arms and hands are burns, cuts, electrical shocks, amputation, and ...

Read.png)