UK Pipe Marking: Regulations vs. Standards

UK Pipe Marking

When it comes to pipe marking in the United Kingdom (UK), there are two commonly cited authorities that many organizations turn towards. The first is a regulation from the United Kingdom: Health and Safety (Safety Signs and Signals) Regulations 1996. The second is a standard: British Standard (BS) 1710:2014.

Regulations and Standards

There is an important distinction between regulations and standards. Regulations are created and enforced by a legislative body. They have the weight of the law behind them. However, they do not always give specific directions on how to comply with them. Standards, on the other hand, may be created by non-governmental organizations such as trade groups, and often provide very detailed recommendations. However, there may be no enforcing body that requires compliance with a standard.

This is true for Regulations 1996 and BS 1710. Regulations 1996 provide some general direction as to how pipes need to be labelled, while BS 1710 goes into exacting detail on how to label pipes. As a result, the contrasting information in the regulation and standard has created some confusion, specifically about colour coding and label placement.

Are Pipe Marking Standards Mandatory?

While standards are generally not required by law, there are some cases where a local code or regulation may require you follow a standard. If your state requires you to follow BS 1710 or another pipe marking standard, then (and only then) the standard is required by law.

In some cases, an organisation will create a set of internal standards which require BS 1710 to be followed. This is, however, an internal requirement and not enforced by a regulatory agency.

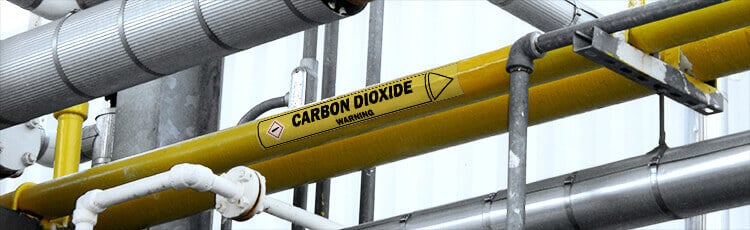

UK Pipe Marking Colour Coding

The first area of confusion revolves around colour coding. This is likely the result of a couple things. First, Regulations 1996 recommends using colour coding, and then it references BS 1710 as a good resource to follow. BS 1710, in turn, provides a comprehensive colour coding scheme for pipe marking. There are 23 different colours, which are broken into the following categories:

- Basic Identification Colours (8 total)

- Safety Colours (4 total)

- Code and Other Colours (11 total)

While BS 1710 is an excellent pipe marking standard and covers many complex areas, a less complex colour coding scheme may suffice.

So what's really required?

- Regulations 1996 recommends using colour coding as a beneficial way to help identify pipes.

Creating and using a simple colour scheme can be beneficial, making it easier for workers to quickly identify a pipe's contents as well as any potential risks. It helps improve safety and efficiency.

UK Pipe Marking Placement

Another area of confusion is the placement of pipe markers. BS 1710 requires both visible and covered pipes to be labelled. Clause 4.5 specifically states that covered pipes must be labelled at intervals no greater than 0.5 m. While precise, this requirement is generally not required by law.

In fact, Health and Safety Executive (HSE), specifically addresses labelling pipes too frequently, stating that pipes should only be labelled where workers may be exposed to a hazard. This includes labelling pipes at filling points, drain valves, flanged joints, and at intermediate points.

In addition, Regulations 1996 specifically states that you should avoid placing too many labels in close proximity because doing so may cause the labels to blend in with the background.

So what's required by Regulations 1996?

- Mark visible pipes at locations where workers may be exposed to a hazard.

- Don't worry about marking covered pipes, unless there is a significant hazard.

- Avoid labelling pipes too frequently (Regulations 1996 does not identify what "too frequently" looks like, but common industry practice is to mark long runs of pipes every 15 m).

Some regions may have special laws governing pipe marking. Check with your local authorities to ensure that you are meeting all legal requirements.

UK Pipe Marking Solutions

Marking your facility's pipes is an important step for a safer and more efficient workplace. Marking pipes and identifying hazardous chemicals is an essential part of any facility's safety programme. DuraLabel offers an array of DuraLabel printers and labelling supplies that will meet nearly any pipe marking application.

Related Resources

BS 1710 British Standard Pipe Marking

British Standard 1710 (BS 1710) provides a robust framework that fulfills the pipe marking requirements set ...

Read

How to Improve Facility Safety with Compliance Labeling

Before beginning work, it's crucial to evaluate your facility for safety hazards. Consistent and effective ...

Read

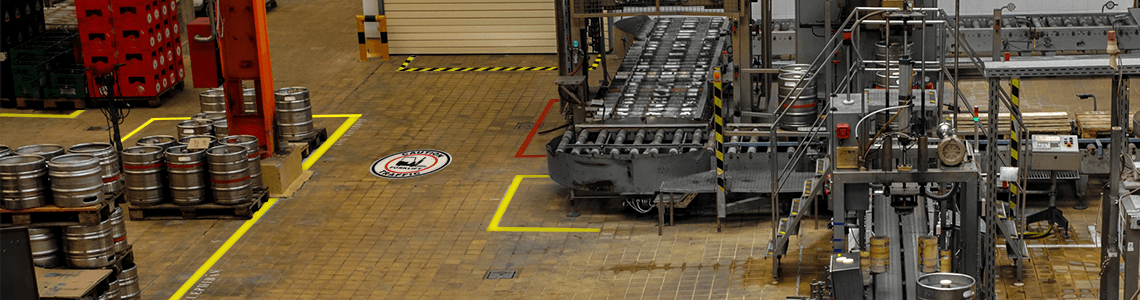

Tips from a Brewer for Effective Floor Marking

Hold My Beer: 5 Floor Marking Tips from a Brewery In the heart of the brewery, every step is important for ...

Read.png)