What Is Kaizen? - The Benefits of Kaizen Explained

Factory production line with heavy machinery illustrating Kaizen benefits—continuous improvement that boosts productivity, reduces waste, improves quality, and enhances workplace safety.

What is Kaizen?

Kaizen is a Japanese philosophy that means continuous improvement with Kaizen. It focuses on making small, incremental changes every day to improve efficiency, reduce waste, and boost quality in business operations. Today, companies implement Kaizen principles to transform how teams work, particularly in Lean Manufacturing and 5S systems.

Kaizen's meaning originated in Japan during the early 1950s and comes from two words: Kai (improvement) and Zen (good). Over time, Kaizen became synonymous for continuous improvement, and today's businesses use it to improve quality, increase productivity, and reduce costs through the elimination of waste.

Unlike other continuous improvement programs, Kaizen, often paired with 5S and Kaizen basics, requires little upfront capital investment because it relies on making small, daily changes that result in major improvements over time.

This is part 1 in our Kaizen educational series for businesses:

- What is Kaizen?

- Kaizen Events, Explained

- Benefits of Kaizen

- Getting Started with Kaizen

- Motivate workers & become a more effective leader with our Kaizen and PDCA Best Practice Guide

Making Kaizen Work for Your Business

Part of what makes Kaizen successful is that it involves all workers, making improvements in every aspect of the business. To this end, there are two main approaches to Kaizen as follows:

- Process Kaizen focuses on changes to individual work areas to make work more efficient.

- Flow Kaizen focuses on changes that improve material and information flow throughout the entire business.

Process Kaizen vs Flow Kaizen

| Feature | Process Kaizen | Flow Kaizen |

|---|---|---|

| Scope | Individual work area | Multiple departments or entire value stream |

| Focus | Improve specific tasks | Improve material and information flow |

| Team Structure | Individual workers or small teams | Cross-functional teams |

| Timeline | Small improvements within days | Larger structured improvements |

| Example | Reducing wasted motion at one workstation | Reorganizing material flow from purchasing to assembly |

| Primary Goal | Eliminate localized waste (muda, muri) | Reduce system-wide inefficiencies |

Kaizen/5S tool organization board with shadow outlines and labeled tool sets, supporting visual management, faster tool retrieval, and lean workplace efficiency.

Process Kaizen

This approach to Kaizen requires workers to begin looking for small improvements they can make in their work area within a day or two. Ideally improvements should be focused on eliminating waste (muda) and work processes that are overly difficult (muri), such as:

- Missing tools or supplies, which cause undue delays

- Tasks that require workers to frequently leave their work area

- Mistakes or errors that are repeated

- Excessive motion (lifting, bending, etc.)

Focusing on individual work areas enable workers from every department to see the results of their improvements-helping Kaizen gain the buy-in it needs to be successful.

Flow Kaizen

While Process Kaizen focuses on individual work areas, Flow Kaizen focuses on making larger changes that impact multiple work areas, using cross-departmental teams. These teams are empowered to make a change within a pre-defined scope of responsibility.

Manufacturing companies, for example, use Flow Kaizen to reorganize how information and materials flow from purchasing, to fabrication, and then to assembly and paint. Through process standardization, teams can begin to:

- Eliminate errors caused by non-standard processes

- Reduce downtime (waiting) caused by materials or supplies not being where they should

- Reduce rework caused by miscommunication between departments

To succeed, each team must be well-trained and supported by management. Changes that impact multiple areas need to involve teams from each area to ensure that the most effective solution is implemented.

How to Implement Kaizen in the Workplace

Kaizen breaks away from the "command and control approach to improvements by replacing time and labor-intensive projects with smaller projects using Plan-Do-Check-Act (PDCA). PDCA is based on the scientific method (hypothesis, experiment, evaluation) and provides an effective way to find problems, develop solutions and apply solutions in a continuous cycle.

Another lean tool used to support Kaizen is known as the 5 Whys. This tool helps workers identify the root cause of a problem by asking a series of questions that dig beneath the surface. For example, the cause of a mistake at the burnout table might first be blamed on the employee. However, by applying 5 Whys, the root cause of the problem might turn out to be a missing dimension on the print, which was caused by a lack of standards in the engineering department. The solution? Create a drawing standard and train the employees to ensure it's used.

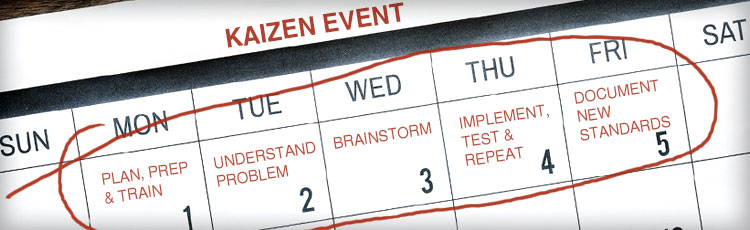

In addition to small, daily changes, businesses have begun to use Kaizen Events or "Blitzes" to address larger issues and realize major improvements in a short period of time. Typically, solutions are implemented within a week or two at most. These events help to prove Kaizen's effectiveness and improve buy-in for the program.

Benefits of Kaizen

While Kaizen has proven its effectiveness by increasing productivity, there are some unexpected benefits. Kaizen nurtures employees through empowerment and education. Employees are taught to use root-cause analysis and other problem solving tools to improve their work experience. At the same time, employees are trusted to develop and implement the solutions they come up with.

Other benefits include:

- Improving quality

- Increasing safety

- Reducing costs

- Increasing customer satisfaction and more

How Can You Start a Kaizen Program?

Are you ready to get started with Kaizen? DuraLabel offers a free, in-depth Kaizen and PDCA Best Practice Guide to help improve efficiency, quality, and profit. This guide provides information that can help you train your employees, as well as direction on where to get started.

Another helpful tool includes proper labeling and signage, enabling workers to:

- Identify the correct workflow

- Perform tasks correctly

- Avoid hazards

- Communicate essential information

Overall, labels and signs help reduce injuries and improve workplace safety. DuraLabel industrial label and sign printers by DuraLabel can help you develop clear, custom visual communication. With a variety of printers and more than 50 specialty supplies, you'll find the right tools for your needs.

Take Action Today

Want to learn how to apply Kaizen principles in your facility? Call us today at 1-888-788-9936. One of our experts will help you integrate continuous improvement with Kaizen into your workflow using proven Lean strategies and industrial labeling tools.

Related Resources

Kaizen Event: Driving Focused Continuous Improvement

What Is a Kaizen Event and How Does It Improve Lean Processes? AKaizen eventis a focused, short-term effort ...

Read

Kaizen Getting Started

There is more to implementing Kaizen than we can include on a single web page. However, the following serves ...

Read

Understanding the 5 Lean Tools: Kaizen, 5S, and More

What Are the Most Helpful Lean Tools for Improving Efficiency? Some of the most effective Lean tools for ...

Read.png)