How to Be a Safety Leader Amid Disruption

Despite the implementations of new safety protocols in most stores, manufacturing facilities, construction sites, and other industrial workplaces, there have been many complaints. The Oregon Occupational Safety and Health Administration has received more than 1,100 complaints due to COVID-19 (coronavirus) concerns, such as a shortage of personal protective equipment, or a lack of safe social distancing. Workplaces can easily step up safety programs and meet guidelines using simple tips and best practices to help curb fears and complaints.

OSHA Complaints Increase

Since COVID-19, Oregon OSHA's complaint process has not significantly changed. Yet, nearly 24 hours after the state issuance of a social distancing executive order, Oregon OSHA leaders said they received 400 complaints.

"That is a tremendous amount," said Aaron Corvin with Oregon OSHA. "That is an unusual volume of complaints and obviously we're living and working in unusual times." Over the next week, more complaints were filed. The agency intends to screen those complaints and conduct inspections.

Among worker concerns regarding coronavirus and workplace safety are a shortage of PPE, such as gloves and N95 masks, general sanitation issues, and a lack of enforcement for safe social distancing in the workplace.

Companies found in violation of workplace safety rules must correct the problem and could face a fine. "When we receive a complaint, a decision is made whether or not an inspection is the best tool to respond to the complaint items," said David McLaughlin, Standards and Technical Manager at Oregon OSHA. "If an inspection is conducted, there can be penalties for any identified hazards to which employees are exposed but the employer had not adequately addressed."

Set Aside Fear

During stressful times and industry changes, workers and workplaces can set fear aside and step up safety. Here are a few tips to help improve leadership and strengthen safety programs amid disruption:

During stressful times and industry changes, workers and workplaces can set fear aside and step up safety. Here are a few tips to help improve leadership and strengthen safety programs amid disruption:

- Encourage workers to speak up: Workplaces can only benefit from having employees who are comfortable sharing ideas for improvement.

- Keep records: Be vigilant in reporting and correcting unsafe behaviors, activities, injuries, and illnesses. Document necessary equipment need and changes, and fulfill them diligently.

- Continuous education: Managers can research ways to improve safety and talk about those improvements with workers. Educate workers so they understand the why behind policies and procedures.

- Stay on top of training: New equipment, staff, and tasks all require training. Utilize resources for compliance and safety. Re-evaluate processes and re-train on them as they change.

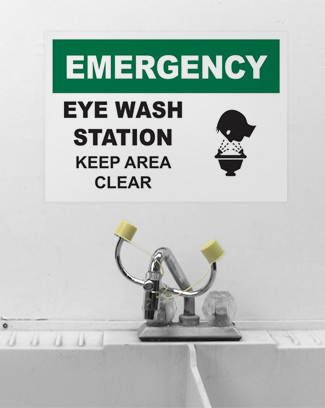

- Share important messages: Keep workplace safety current through bold visuals that inform workers. Meet OSHA requirements for safety signs. Create visual boundaries using floor tape to mark walking and working surfaces.

Workplaces can benefit from strong safety programs and leadership, effective resources, and continuous education and training. It doesn't take much for workplaces to keep up with safety reinforcement. Use daily safety talks during pre-shift meetings, go over weekly safety briefings, and discuss the changing circumstances at the worksite.

Implement a safety program, perform a job hazard analysis, and control hazards in the workplace using our free EHS Managers Guide.

Related Resources

Core Elements of Successful EHS Management

While each business and facility is unique, there are key parts that make a complete and thorough health and ...

Read

Marine Corps Air Facility Adds App, Steps Up Safety Program

A safety team at the Marine Corps Air Facility (MCAF) in Quantico, Virginia, tackled safety issues and ...

Read

Safety and Health Program Management Guidelines

The Safety and Health Program Management Guidelines provide employers and workers with a sound, flexible ...

Read.png)