Industrial Laser Use Grows, as Do Safety Controls and Cautions

03

February,

2023

2 MINUTE READ

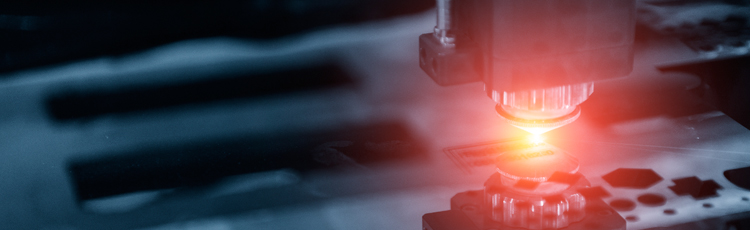

After years of precursory work by engineers and scientists, in 1960, an American physicist was able to generate an intense, very narrow beam of light of a single wavelength. Since then, fascinations, imaginations, and new discoveries using Light Amplification by Stimulated Emission of Radiation, or laser technology, have spiraled. The industrial laser market in 2017 grew by 26% with a more modest growth expected for 2018 driven by developments in fine metal, non-metal, and additive manufacturing, according to a report by David Belforte, chief editor of Industrial Laser Solutions.

Laser Use Increasing

Industrial interest in lasers has grown, propelling developments in additive manufacturing, also known as 3D printing. In additive manufacturing, components are created from nothing more than powder and laser light. Industries that are practicing this type of manufacturing include aerospace, automotive, medical, dental, sciences, and retail. Some of the uses include cutting, welding, surveying, marking, and cladding. Within the medical sector, custom models and parts are cost-effective to build without sacrificing strength. Recently, 3D printing has found applications in dentistry to create crowns and bridges, and it is moving toward the ability to create permanent restorations in dental composites.

Industrial interest in lasers has grown, propelling developments in additive manufacturing, also known as 3D printing. In additive manufacturing, components are created from nothing more than powder and laser light. Industries that are practicing this type of manufacturing include aerospace, automotive, medical, dental, sciences, and retail. Some of the uses include cutting, welding, surveying, marking, and cladding. Within the medical sector, custom models and parts are cost-effective to build without sacrificing strength. Recently, 3D printing has found applications in dentistry to create crowns and bridges, and it is moving toward the ability to create permanent restorations in dental composites.

The paradigm shift toward additive manufacturing carries the promise of producing complex objects without using any tools. Steady progress is being made, albeit slowly. It is very suitable for a manufacturing environment where products assembled vary in application, lot size, and production processes, said Anand Prakasam, head of EOS India. However, Gordon Styles, president and founder of Star Rapid, says lack of design for manufacturing knowledge is delaying full-on adoption of this technology for additive manufacturing. Learning takes time and mastering takes experience. Another hold up, he said, is that 3D printing technology is slow and expensive. "Despite it being years away from true commercial viability, it can certainly find niche applications right now," he said.

Laser Safety Controls

According to the U.S. Department of Energy Berkeley Lab, the chief concern over laser use is the possibility of eye and skin injuries. Eye injuries drive the need for workplace laser safety, funding, controls, and application. Biological effects from direct exposure and diffuse reflection exposure will differ. The American National Standards Institute has compliance standards for laser safety in the United States: ANSI Z136. Here are several tips to communicate laser hazards and safety in additive manufacturing:

- Communicate laser classification, laser parameters, and optical density requirements for laser eye wear on laser hazard warning signs

- Post signs/procedures (or equivalent) near the laser control panel to communicate changing operation modes

- Post emergency entry procedures, including a description of how the laser hazard is disabled, near the control area entry

- Post a visitor policy near the laser working area

- Display a core laser safety practices poster

- Label emergency off buttons

Lasers are used in industry for a variety of applications. As this technology develops, so must workplace safety plans. Materials processing with high-powered lasers can include cutting, drilling, and welding, which harbor potential hazards. Warn of the dangers and display precautions associated with lasers using custom or premade laser safety signs and labels. Communicate and highlight the importance of wearing proper personal protective equipment where a laser is present, for dust particle protection, vision and skin protection, and more. Duralabel is an innovative global leader in industrial label and sign printers, providing compliance and educational resources to protect workers. Produce OSHA/ANSI compliant labels with an industrial label and sign printing system, such as the versatile and easy-to-use DuraLabel Toro. For more information about products and services, call 888-326-9244.

RELATED RESOURCES

OSHA and Ironworkers Partner for Safety Outreach

OSHA and Ironworkers are partnering up to help boost safety programs and prevent the most common injuries, ...

Read

Biggest OSHA Sign Compliance Challenges

When it comes to signs in the workplace, opinions vary on why they are necessary and if they even work. One ...

Read

4 Signs Your Safety Communication Needs an Update

Safety signs and labels that are up to date, clearly worded, and in tact play a key role in achieving ...

Read.png)