4 Signs Your Safety Communication Needs an Update

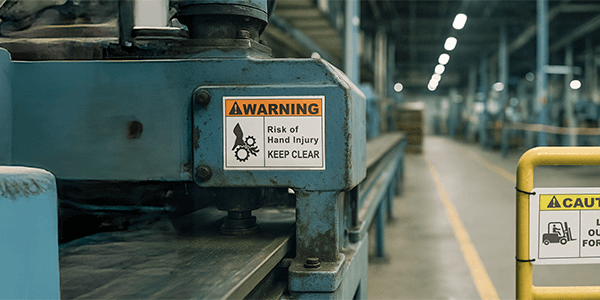

Industrial workplace settings require a high level of concentration. Even with the most astute mental focus, mistakes can happen. With newer technology, such as wearable eye trackers, job hazard studies can pinpoint and provide a window into what a worker might see and how they behave while performing a task. Noticeable signs and labels are fundamental measures for workplace safety communication to reinforce behavior and help prevent injuries. However, they do not do any worker good if they are failing, missing, add to clutter, and are not up to date.

Evaluate Existing Safety Signage

Safety managers and workers should thoroughly evaluate the worksite both inside and out using a job hazard analysis. Utilize free tools and resources for facility safety management and OSHA safety signs. Here are a few points to keep in mind when evaluating communication needs in the facility.

1. Look for missing or incorrect signs and labels

- Have labels or signs fallen off due to incorrect, weak label materials used?

- Have processes changed due to new or updated equipment?

- Have regulations changed that require new signs and labels?

Re-examine the facility's safety communication. Correct messages that are amiss or processes that have changed for workers handling hazardous tasks.

2. Evaluate for wear and tear

- Has indoor lighting or outdoor weather deteriorated signs?

- Has text become smudged or worn off due to abrasive environments?

- Are signs cracked, peeled, or partially unreadable due to harsh outdoor environments?

Replace old or worn safety signs and labels with a supply that is long-lasting and can stand up in harsh environments made from industrial grade adhesives and materials.

3. Ensure signs have organization and are clear

- Are there conflicting messages that confuse?

- Are signs at the point of need where they are most relevant?

- Are signs hidden among surrounding elements?

Strategically place signs and labels from a reasonable, readable distance. Use bold, succinct messages to quickly attract a worker's attention. Keep messages organized to prevent visual clutter or confusion.

4. You've had an injury, accident

- Have accidents occurred and could signs have helped?

- Are procedures marked in the area work is to be performed?

- Are emergency exits, equipment, and phone numbers marked?

Lack of adequate precautionary information can also lead to lawsuits, heavy OSHA citations, and days away from work. Increase sign and label visibility with a combination of floor markings.

Be a Leader in Safety Communication

Help prevent injuries on the job by employing a strong workplace safety program. Facility managers should make time to regularly evaluate, update, and replace safety communication as necessary. When a workplace's communication is clear, organized, and in line to address hazards, employees can work safely with confidence.

Related Resources

How Custom Signs Support OSHA Rules and ANSI Signage Requirements

Why Do Facilities Need Custom Signs to Meet OSHA Rules and ANSI Signage Requirements? Custom signage plays a ...

Read

Everything You Need to Know To Be OSHA Signs and Labels Compliant

How Does OSHA Signage Compliance Support Workplace Safety? Occupational Health and Safety Administration ...

Read

Redefining Job Site Safety Through Better Custom Labeling

How Do Contractors Use Labels and Signs for Better Job Site Safety? The final steps of a project are just as ...

Read.png)