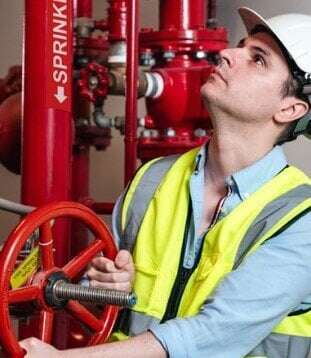

Pipe Marking Best Practice Guide

Implementing or updating your pipe marking system is crucial for improving workplace safety and operational efficiency. This comprehensive guide provides an in-depth look at the ANSI/ASME A13.1 standard, helping you identify the contents of all facility pipes with the correct label sizes, colors, and positioning. Industry-specific systems are also covered to ensure your facility meets regulatory standards.

- Step-by-step guidance on pipe labeling

- Information on ensuring compliance with regulations

- Practical insights for improving operational safety

Download the guide today to streamline your pipe marking process and enhance facility safety!

ANSI/ASME A13.1 Labeling Standards

Proper Label Sizes and Placement

Color Coding for Safety and Efficiency

Industry-Specific Pipe Marking Systems

Why Choose DuraLabel?

- Over 50 years of trusted safety expertise.

- Find the right solutions for your specific safety needs.

- Stay informed on how regulations impact your worksite.

- Connect with experts ready to help you solve challenges.

- Learn how to easily create custom labels for your facility.

- Improve both safety and efficiency across your operations.

Related Resources

Construction Safety Best Practice Guide

This essential resource is designed for construction site safety managers, general contractors, and ...

Go to GuideBronco Max Buyer's Guide

Discover the advantages of a reliable industrial sign and label system built for performance. The Bronco Max ...

Go to GuideKodiak Max Buyer's Guide

The DuraLabel Kodiak Max Print System delivers unmatched ease, precision, and durability for in-house sign ...

Go to Guide.png)