Achieve IUID Compliance with Thermal Transfer Printing

What is the Goal of the IUID System?

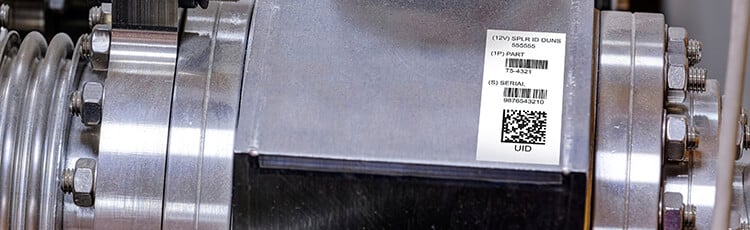

The Item Unique Identification (IUID) or MIL-STD-130 standard was created by the Department of Defense (DoD) to ensure every asset is traceable across its entire lifecycle. By assigning each item a unique identification code, the system improves accuracy in tracking, speeds up data collection, and reduces errors in logistics and reporting.

Beyond compliance, the IUID system delivers efficiency and security for both the Department of Defense and its contractors. Traceability matters more than ever as supply chains expand, counterfeit risks increase, and defense budgets tighten. A single lost or mislabeled asset can ripple into millions of dollars in wasted resources or mission delays. These benefits set the stage for understanding how compliance is achieved—and why thermal transfer printing is the most practical path forward.

How IUID Benefits the Department of Defense and Contractors

Although the labeling requirements can be challenging, the benefits of this method of tracking ultimately outweighs the task. Both the military and its contractors gain measurable improvements in oversight, security, and efficiency.

Both the military and its contractors gain:

- Total Asset Visibility (TAV): At any point during the shipping process, authorized personnel can view the location, ownership, and condition of a serialized item. This eliminates duplicate records and reduces confusion across multiple facilities or handoffs.

- Streamlined asset management: Consolidated data reduces manual entry errors and prevents mismatched records. Contractors can link physical items directly to digital documentation, simplifying audits and contract reviews.

- Counterfeit and theft prevention: Unique identification codes make it significantly harder for counterfeit or stolen parts to enter the supply chain. This reduces risk not only to equipment integrity but also to mission readiness and national security.

- Maintenance and lifecycle tracking: When serialized items are logged through IUID, maintenance records become accessible in real time. Technicians can quickly identify service history, order replacement parts, and return assets to operation faster.

- Faster service turnarounds: By linking each asset to its maintenance and part requirements, IUID reduces downtime for critical equipment. A failed component can be identified, repaired, or replaced with greater efficiency.

- Cost Savings Across the Board: Increased efficiency benefits the DoD, contractors, and ultimately taxpayers. More accurate asset management translates into fewer wasted resources, reduced delays, and better use of existing equipment.

To achieve compliance, your labels must remain legible and permanent for the entire lifecycle of your products. Thermal transfer printers are recommended by integration experts as a proven compliant method for producing IUID labels and markings.

What Happens if You Don’t Comply with IUID Requirements?

Failure to meet IUID standards isn’t just a paperwork issue—it directly impacts contracts, timelines, and trust with the Department of Defense. When labels don’t meet MIL-STD requirements, the entire supply chain slows down, inspections become more difficult, and accountability breaks down. For contractors, that means serious consequences.

The penalties for noncompliance extend beyond rejected labels. Contractors may face:

-

Shipment delays due to labels being returned or flagged for rework

-

Financial losses from contract penalties or re-labeling costs

-

Audit complications during DoD reviews or inspections

-

Damaged reputations that affect eligibility for future defense contracts

In short, compliance with MIL-STD standards isn’t optional. It is directly tied to contract performance, payment, and long-term credibility.

What Do MIL-STD-129R and MIL-STD-130N Require?

The IUID system doesn’t stand alone. It’s supported by detailed military standards that spell out exactly how assets and shipments must be marked to remain traceable. Two of the most important are MIL-STD-129R and MIL-STD-130N. These documents define how labels should look, what information they must contain, and how long they must last.

MIL-STD-129R (Revision R, Change Notice 3) is the most updated version of the standard that focuses on military marking for shipment and storage. It updates earlier versions and clarifies requirements for container labels, barcodes, contract/order identifiers, and other shipment-logistics data. The change reflects the DoD transition to lifecycle management of serialized items using programs for IUID and serialized item management.

MIL-STD-130N is the latest version of the standard released in 2012 which focuses on military marking requirements for individual items produced, stocked, stored, and issued for or by the DoD. The revision provides clarification, guidance, and marking criteria regarding the implementation of machine-readable information (MRI) for item identification marking and automatic data capture.

Together, these standards ensure that identification is consistent across thousands of contractors and millions of items.

Simplify Compliance with Thermal Transfer Printers

Meeting IUID requirements isn’t only about what information goes on a label — it’s about whether that label can survive the environments where military assets actually operate. From desert heat to saltwater exposure, labels are expected to remain scannable and intact for years. Many printing methods struggle to meet that standard, which can lead to rejected shipments, contract penalties, or delays in critical missions.

Unlike inkjet or laser methods, thermal transfer creates crisp, high-contrast barcodes that meet machine-readable information (MRI) scanning requirements. It’s the only approach that consistently delivers both durability and precision.

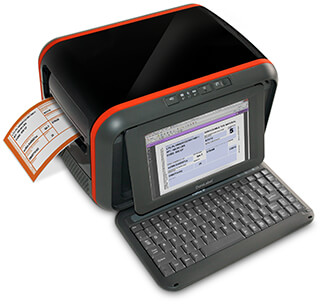

DuraLabel Industrial Label Printers for IUID Compliance

Thermal transfer technology sets the standard, but the equipment you choose makes or breaks the process. Not all printers are built to handle the unique demands of military labeling — from strict barcode accuracy to security requirements in the field. Contractors need a solution that goes beyond basic compliance, offering durability, mobility, and the flexibility to support broader facility labeling needs.

To meet those needs, DuraLabel provides a complete system that includes industrial label printers, supplies, software, and scanners designed to work together for full IUID compliance.

Toro Max for Military Applications

The DuraLabel®Toro® Max makes compliance straightforward with built-in capability to print MIL-STD-129R and MIL-STD-130N labels and barcodes. For military-partnered contractors, a dedicated version of the Toro Max is pre-configured for high-security environments. With no networking capability, it eliminates cybersecurity concerns while remaining portable and self-contained. An optional battery allows continuous printing for up to three hours without external power.

Durable Supplies for Harsh Environments

Even the best-printed code is only as strong as the material it sits on. IUID labels are expected to last through years of wear, and standard stock just won’t cut it. That’s why DuraLabel supplies are engineered for extreme conditions — resisting weather, oils, and chemical exposure while staying legible for the full asset lifecycle.

LabelForge PRO Software Integration

Hardware is only half the equation. Compliance depends on fast, error-free design and data management. LabelForge® PRO label design software streamlines the process by letting contractors design and produce compliant labels quickly. Key capabilities include:

- Generate linear and 2D Data Matrix barcodes

- Choose from more than 20 barcode formats

- Easily import data from a database or spreadsheet to quickly create custom asset tags and labels

- Make a variety of labels for improved asset management, inventory control, shipping, and more

This combination of automation and flexibility makes LabelForge PRO a powerful partner for meeting IUID standards.

Seamless Data Capture

Seamless Data Capture

Printing a compliant label is the first step, because the information on that label has to integrate seamlessly into the asset management system. Reliable data capture ensures every record stays accurate, whether it’s tied to a serialized part, a container, or a condition tag.

To support this, the DuraLabel Toro Max comes pre-loaded with templates for materiel condition tags, making it easy to standardize this critical part of IUID compliance. As described in MIL-STD-129R, materiel condition marking: "shall be used whenever materiel may become mixed during storage or shipment within or between installations, or where physical evidence is necessary for materiel control to prevent duplicate inspections, or both."

Together, these tools give contractors a proven system for meeting IUID requirements while improving efficiency across the rest of their operations.

DuraLabel IUID Resources

In defense operations, reliable asset tracking is as critical as the assets themselves. IUID labels provide that reliability by ensuring every part, shipment, and piece of equipment can be identified throughout its lifecycle. To meet this challenge, DuraLabel offers a complete system of printers, supplies, and software designed for mission-ready compliance.

DuraLabel offers a complete system designed for mission-ready compliance. The Toro Max Industrial Sign and Label System provides secure, portable printing for IUID and MIL-STD labeling, while durable supplies withstand abrasion, chemicals, and extreme conditions. Paired with LabelForge PRO software and integrated barcode scanning, contractors gain a reliable end-to-end solution for producing and managing compliant labels.

To support long-term compliance goals, the free DuraLabel Guide to Printer Supplies provides detailed instructions for selecting the right materials and adhesives for any application. It includes breakdowns of supply types, durability ratings, and best practices for keeping labels intact throughout the asset lifecycle. This resource helps contractors match the right supply to each environment, ensuring compliance doesn’t fail in the field.

Have questions about IUID labeling or supply compatibility for your facility? Call 1-888-820-4631 and a DuraLabel specialist will guide you through the process.

Read Next:

What Is HazCom? A Guide to Chemical Labeling, GHS, and OSHA Standards

Mission-Ready Fire Safety: How Labeling Protects Military Assets

Related Resources

Efficient Use of Barcoding Labels for Smarter Facility Management

With today’s technological advancements, much of the work force is searching for ways to become more ...

Read

Why Upgrade to the DuraLabel Toro Max Industrial Sign and Label System

Why Would Facilities Upgrade to a Toro Max Printer? Facilities upgrade to the DuraLabel® Toro® Max Industrial ...

Read

Why Upgrade to the DuraLabel Bronco Max Industrial Sign & Label System

What Is a Bronco Max Printer Used For? The DuraLabel® Bronco® Max Industrial Sign and Label System is used to ...

Read.png)