Andon System for Visual Alerts in Lean Manufacturing

.webp)

When a worker identifies a problem with the process, he pulls a rope known as an andon rope. The andon rope activates a light known as an andon light; generally this is accompanied by an andon tone. As long as the process has not advanced to the fixed position stop, the andon light turns yellow and this activates a light on an andon board. The andon board is located in a central location, where it can be monitored by the supervisor.

What is happening here? What is an andon and what are these ropes and lights for?

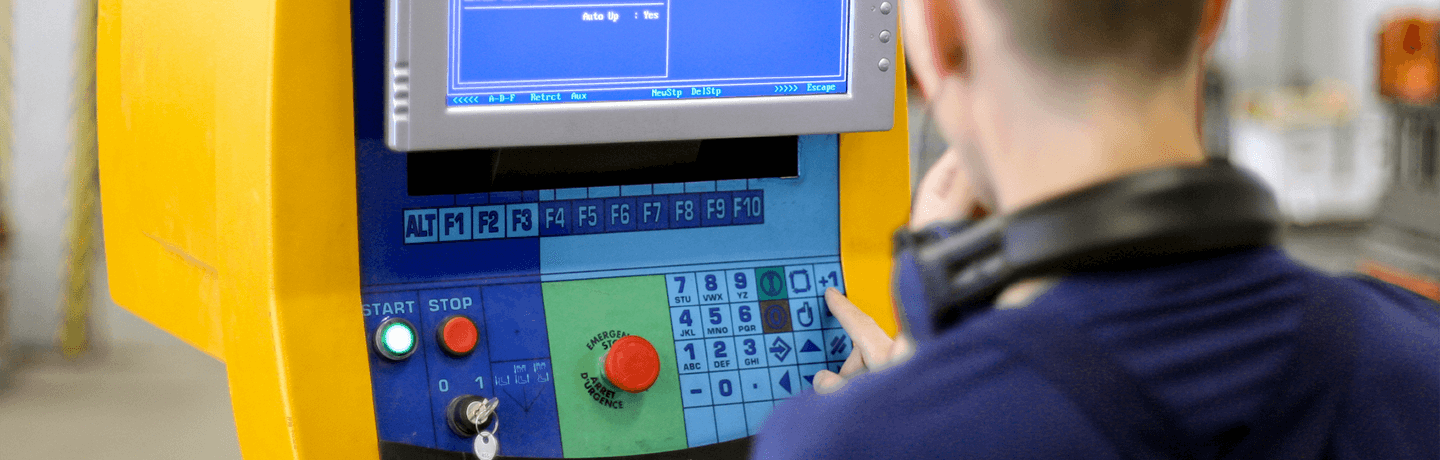

An andon is a visual display that uses lights to show the status of a machine or process. In the above example, the andon is activated manually. However, andons may also be activated automatically by equipment, machine, and process control systems.

The above quote is an example of an andon used for an assembly line. A worker has noticed a problem and pulled the rope that activates the yellow andon. However, the production line keeps moving. It will continue to move until an item on the production line reaches a fixed point at which the line will be forced to stop. This allows time for the problem to be fixed without stopping production. If the problem is fixed in time, the andon will turn off and the production line will simply keep moving. However, if the production line reaches its fixed stop point before the problem is fixed, the andon light will change to red, and the line will be stopped.

Andon Definition

An andon is a means of visual communication, useful in lean methodologies as varied as TPM and Sig Sigma, typically using lights to indicate the presence and location of a problem. It also may incorporate other means of signaling, such as sound.

Jidoka and Andons

Jidoka is a lean method for quality control in the Toyota Production System. It is defined as "automation with a human touch." The automated system is able to recognize when a problem exists, stop its own operation, and alert a human attendant. At this point, the human can exercise judgment and respond appropriately.

Jidoka is combined with andon to provide a visual method to communicate the status of the system to human operators. A signalboard with many lights visually shows the status of all of the equipment within a certain area or process. In this system, the signalboard itself is called an andon. In computerized systems, the signalboard may be replaced by a computer display that uses lights to indicate the locations of problems, and the lights may be supplemented with text.

With this type of system, a single worker can monitor and control a large number of machines or systems. Should a problem be encountered, the automation will stop production, and the andon will signal the location of the problem.

Paging andons are often used to request supplies of parts for the production line. When parts are about to run out at a process, the operator sends out a signal that lights the andon. This notifies the people who operate the parts supply system.

Although the term "andon" is commonly used for lights used in lean manufacturing systems, in other applications this type of light is called an indicator light.

Related Resources

Six Sigma Principles: Exploring Six Sigma, Lean, and The 5S System

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S ...

Read

Kaikaku: Driving Radical Change in Lean Systems

What Is Kaikaku and How Does It Support Lean Transformation? Kaikaku is the Japanese word for "radical ...

Read

8D Methodology

The 8D methodology (8D=eight disciplines) was developed in Ford Motor Company in the mid-1980s to be used by ...

Read.png)