How 5 Industries Rely on Custom OSHA Signs to Cut Hazards

How Can Construction Safety Signs Reduce Injury Risks in Fast-Paced Job Sites?

Construction safety signs reduce injury risks by providing clear, site-specific warnings that adapt to constantly changing conditions. When custom OSHA signs are used for shifting layouts, PPE zones, and temporary hazards, are used for portable barriers, multilingual PPE instructions, and temporary floor markers, workers get quick visual cues that helps prevent falls, struck-by incidents, and equipment collisions.

The sections below explain why construction needs job site specific signage and how custom signs reduce risk.

-

Why fast paced sites need custom OSHA signs

-

How changing layouts create signage gaps

-

Where falls, struck by, electrocution, and caught in between risks show up

-

What types of safety signage work best in construction

-

How portable and multilingual signs reinforce safe decisions

On construction sites, the biggest signage advantage is responsiveness. Signs need to move when the work moves, stay readable in chaotic conditions, and communicate the same warning clearly across mixed crews and languages.

According to the Occupational Health and Safety Administration (OSHA), construction accounted for 19% of all workplace fatalities in 2023, despite representing only 6% of the workforce. OSHA’s “Fatal Four” hazards includes falls, electrocution, struck-by, and caught-in/between. These hazards cause roughly 65% of construction deaths annually.

Dynamic job sites require signage that evolves with changing layouts. That same principle applies to manufacturing, where the hazards move with the machinery.

Controlling Manufacturers Hazards with Safety Signage

Machine safety signage protects operators by clearly identifying moving parts, pinch points, and lockout/tagout (LOTO) locations where injuries are most likely to occur. Durable labels withstand heat, vibration, and chemical exposure, while QR codes on industrial custom labels provide instant access to procedures and maintenance instructions.

The National Safety Council (NSC) reports that contact with objects and equipment is the second-leading cause of workplace injuries, and machine guarding violations (29 CFR 1910.212) remain among OSHA’s top 10 most-cited standards. Incidents involving moving equipment often result in:

- Extended downtime

- Workers’ compensation claims

- Costly regulatory penalties

Beyond compliance, machine signage builds operator confidence and standardizes communication. Facilities can consolidate hazard icons, bilingual instructions, and LOTO steps into one durable label to reduce confusion across shifts. Some sites now integrate digital connectivity into their signage, such as scannable codes linking to step-by-step repair videos, maintenance logs, or inspection schedules. This turns each label into a functional safety tool that streamlines both operations and audits.

While machinery hazards are the primary concern in manufacturing, multi-use facilities must also communicate overlapping chemical and sanitation risks to diverse teams.

HazCom Label Gaps Put Food Processing Plants at Risk Without Custom OSHA Signs

Hazard communication labels help food-processing facilities maintain compliance by making chemical and sanitation risks visible to all employees and inspectors. In environments where cleanliness and accuracy are critical, these labels serve as frontline safeguards against contamination, equipment misuse, and regulatory violations.

GHS-compliant labels, color-coded floor markers, and durable visual indicators enable workers to identify hazards quickly, even in wet or frequently sanitized areas. Chemical containers, cleaning stations, and mixing zones often require signage that withstands repeated washdowns while staying legible and intact.

OSHA’s Hazard Communication Standard (29 CFR 1910.1200) is consistently one of the most frequently cited workplace violations. Food-processing plants are particularly vulnerable, as missing or unclear labels can lead to audit failures, product contamination, or costly shutdowns.

Standard labels rarely survive food plant conditions for long. That’s why facilities lean on custom signage that can combine hazards, stay readable through washdowns, and communicate clearly across crews.

Custom signage solutions address these challenges by:

- Combining multiple hazard warnings into a single, space-efficient sign

- Incorporating bilingual messaging and ANSI-recognized pictograms

- Ensuring durability against moisture, cleaning chemicals, and high traffic

When paired with floor labeling, rack signs, and visual work instructions, hazard communication labels create a safety system that works across shifts and departments. The result is safer operations, cleaner audits, and fewer workflow disruptions.

Aviation Crews Rely on Custom OSHA Signs in High-Risk Work Zones

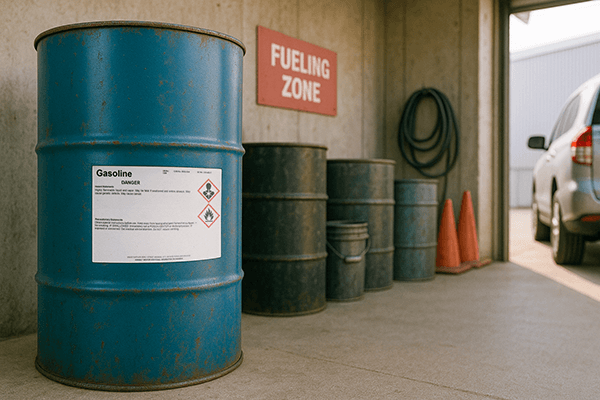

Aviation safety signage reduces risk by helping personnel through high-traffic areas like runways and hangars. High-visibility floor markings establish safe movement paths in these environments, where even a minor misstep can have serious consequences.

Custom safety signage in aviation addresses three critical needs:

- Regulatory precision: Hangar floor markings, fueling zone identifiers, and GHS-compliant chemical labels keep operations aligned with both U.S. and international safety standards.

- Environmental durability: Signs must withstand jet fuel exposure, ultraviolet (UV) light, weather extremes, and constant foot and vehicle traffic without fading or peeling.

- Global workforce communication: Multilingual warnings and universally recognized pictograms ensure international crews and contractors can follow safety protocols without hesitation.

Modern aviation operations also use temporary, magnetic, or removable labels during maintenance projects. This flexibility allows ground crews to mark hazards quickly and remove the signage without damaging surfaces, preserving a pristine and professional work environment. From wing-walk markers to emergency fuel shutoff indicators, every label functions as part of a larger, precision-driven safety system.

How Custom OSHA Signs Supports Dynamic Warehouse Safety and Traffic Flow

Custom signage supports warehouse safety by guiding traffic, marking temporary hazards, and adapting to constant layout changes. In environments where workers operate in close proximity, signage provides clear visual communication that supports safe navigation and efficient workflow. It’s often the first line of defense when layouts change or new hazards emerge.

Warehouses and distribution centers are designed for speed, which comes with risks. As inventory rotates, work zones shift, and traffic patterns change, the likelihood of miscommunication and collisions rises. Without clear visual management, collisions and workflow interruptions become more likely.

Expanding the visual system with custom safety signage improves both safety and efficiency. Facilities often use color-coded systems to organize movement and storage, making navigation safer and more efficient. Temporary labels on pallets or equipment can help prevent mis-ships and inventory damage. When paired with lean 5S programs, this visual approach transforms a busy warehouse into a safer, more organized, and compliant operation.

Across industries, the pattern is clear. Custom safety signage is not an accessory. It is an essential tool for risk reduction, operational control, and long-term compliance.

DuraLabel Custom OSHA Signage Resources

Custom safety signage does more than warn. It ensures compliance and clarity in demanding environments. Industries such as aviation, construction, and food processing depend on signage that can adapt to changing conditions while meeting OSHA and ANSI standards.

DuraLabel’s free OSHA Signage Quick Start Guide provides a practical overview for evaluating your current signage, selecting the right materials, and aligning with ANSI Z535 and GHS requirements.

For facilities that need on-demand, site‑specific solutions, the DuraLabel® Toro® Max Industrial Sign and Label System makes it easy to create durable, compliant signs wherever they are needed.

Need expert guidance? Call 1‑888‑789‑7964 to speak with a DuraLabel signage specialist and enhance your facility’s safety and compliance.

Read Next:

What Is HazCom? Your Guide to Chemical Labeling, GHS, and OSHA Standards

Related Resources

The Key to Reliable Construction Projects: Safety Signage That Works

Construction signs and labels play a crucial role in protecting workers and keeping projects on schedule. ...

Read

Top 5 Challenges Mechanical Project Managers Face

What Are the Biggest Obstacles Mechanical Project Managers Face? Mechanical project managers oversee ...

Read

How Contractors Use Custom Safety Labels for Job Site Safety

What Types of Labels Are Best for Construction Sites? The best labels for construction sites are durable, ...

Read.png)