The Overlooked Fix That Improves Electrical Panel Safety

How Do Electrical Panel Labels Improve Safety and Compliance?

Electrical panels are essential to every facility’s infrastructure and serve as control points for electrical circuits. They also pose significant risks if improperly handled or maintained. The National Institutes of Health (NIH) reports concerning statistics on electrical hazards:

- 400 high-voltage electrical injuries per year

- 30,000 non-fatal shock incidents per year

- 1,000 deaths per year

Maintaining electrical panel safety is a critical part of any workplace safety program. A well-planned labeling system not only ensures compliance but also establishes a consistent visual language workers can quickly recognize in high-risk situations. Labels play a vital role in warning about hazards and providing essential operating information.

Effective electrical panel safety comes from combining compliant labeling, strict regulatory adherence, and clear visual communication that identifies hazards and reduces risks in industrial environments.

The Dangers of Improperly Labeled Electrical Panels

Unlabeled or poorly labeled electrical panels present serious risks. Without accurate information, workers may underestimate the hazards of working near or on electrical panels, exposing themselves to shocks, burns, or even fatal electrocution. Because many panels look similar, unclear or missing labels increase the chance that employees will access or service live equipment by mistake.

Key Elements of Effective Electrical Panel Labels

Not all electrical panel labels are created equal. To be effective, they must do more than simply exist. Labels need to communicate hazards quickly, clearly, and in a way that holds up under the tough conditions of industrial environments.

The following elements define strong, compliant labeling systems.

Color Coding

OSHA and ANSI define color standards for safety signs, making it easier to communicate hazard severity at a glance.

- Red labels: Indicate immediate danger, often associated with high voltage or arc flash risks.

- Yellow labels: Signal caution and warn of potential hazards.

- Green labels: Often used for instructional messages related to safe operation.

Consistent use of these colors across all electrical panel labels helps workers instantly recognize the type of hazard they face.

Text Clarity

Text on electrical panel labels should be clear, concise, and easy to read. Large, bold fonts are especially important in areas with dim lighting or outdoor environments. For example, a label such as “Danger: High Voltage – Keep Away” in bold, high-contrast lettering helps prevent accidental contact with live parts.

Pictograms and Symbols

Pictograms provide a universal communication method that transcends language barriers. ANSI Z535 defines standardized symbols for electrical hazards. Common examples include:

- A lightning bolt to represent electrical shock.

- The arc flash symbol to indicate high-energy electrical discharges.

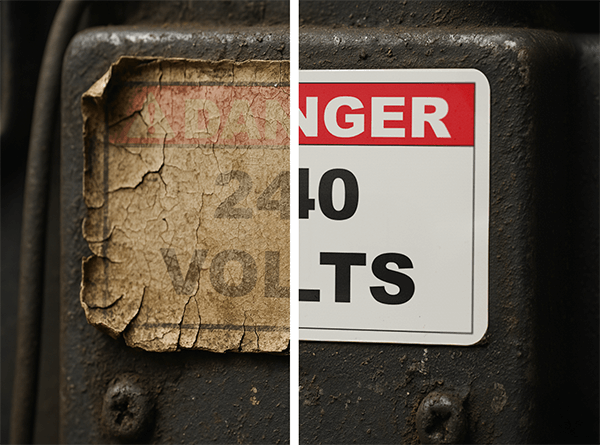

Location and Durability

Labels should be placed in prominent, easy-to-see locations, ideally near the specific hazard. Because electrical panels are often exposed to extreme temperatures, moisture, chemicals, or sunlight, label materials must be durable, weather-resistant, and capable of remaining legible over time.

Compliance with Electrical Labeling Standards

Following the correct standards for electrical labeling is not just a matter of safety—it’s a legal requirement. Several regulations dictate how electrical hazards must be communicated in the workplace, including OSHA standards, NFPA 70E requirements, and NEC guidelines.

OSHA (Occupational Safety and Health Administration)

OSHA requires that electrical panels and other hazardous equipment be labeled to protect worker safety. Regulations specify that electrical equipment must be clearly marked with warnings, including any danger related to electrical shock or high-voltage exposure.

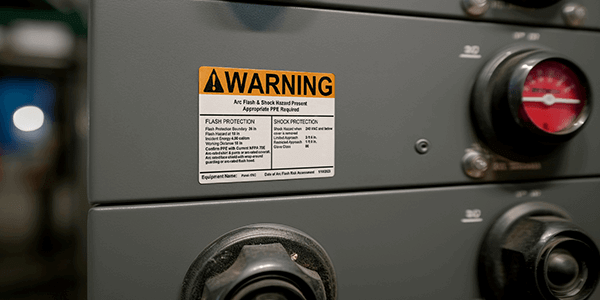

NFPA 70E (Standard for Electrical Safety in the Workplace)

NFPA 70E labeling requirements sets detailed requirements for identifying electrical hazards, including specific rules for arc flash labeling. Arc flash labels must indicate the potential hazard, the appropriate personal protective equipment (PPE), and other critical information needed to protect workers.

NEC (National Electrical Code)

The NEC requires compliant labeling for electrical panels, particularly for equipment operating at high voltages. Labels must provide adequate warnings about potential risks and include clear instructions for safe operation.

By complying with OSHA standards, NFPA 70E labeling rules, and NEC guidelines, facilities can protect employees, reduce risks, and avoid potential fines or legal liability.

Types of Labels for Electrical Panel Safety

Different types of electrical panel labels address a range of hazards and help workers understand the specific risks present.

Warning Labels

Warning labels alert workers to the general dangers of working with electrical panels. Common examples include “High Voltage,” “Electric Shock Hazard,” or “Do Not Open While Energized.” These labels often use orange backgrounds and bold text to capture attention quickly.

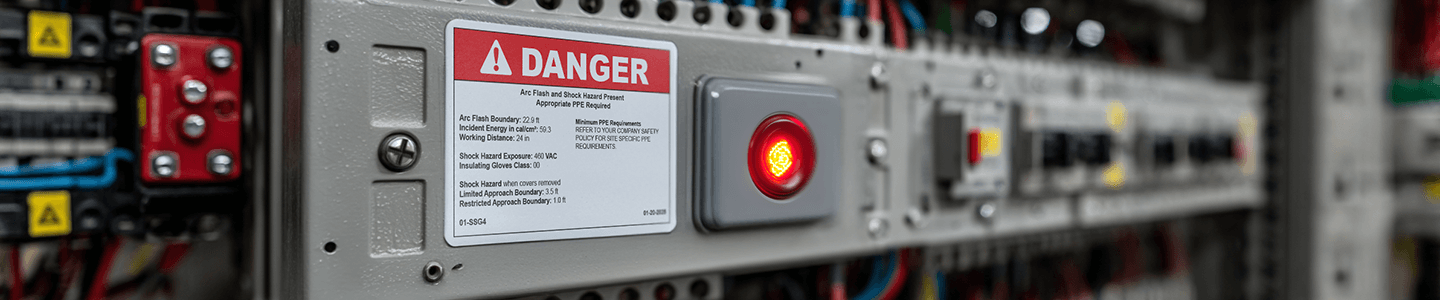

Arc Flash Labels

Arc flash labels identify equipment that could release dangerous energy during a fault. They provide details such as arc flash boundaries, incident energy levels, and required PPE.

Example: “Warning: Arc Flash Hazard – PPE Required: Face Shield, Gloves, Protective Clothing. Incident Energy: 8 cal/cm².”

Lockout/Tagout Labels

Lockout/tagout labels are essential during maintenance, signaling that electrical panels are de-energized. They typically include space for the worker’s name and the date of the lockout.

Instructional Labels

Instructional labels guide the safe operation of electrical panels. They may include step-by-step shutdown, isolation, or restart procedures.

Benefits of Correctly Labeled Electrical Panels

Applying accurate and compliant electrical panel labels deliver measurable improvements in both safety and compliance. These labels not only meet regulatory requirements but also reduce accident risks and streamline maintenance tasks.

Clear, compliant electrical panel labels provide the following advantages:

- Compliance with Regulations: Ensures alignments with OSHA electrical safety standards, NFPA 70E labeling requirements, and NEC guidelines.

- Improved Worker Safety: Reduces the risk of electrical accidents by clearly identifying hazards.

- Faster Emergency Response: Gives first responders and staff the information they need to act quickly and effectively.

- Reduced Maintenance Risks: Makes maintenance safer and more efficient with clear lockout/tagout and hazard instructions.

DuraLabel® Resources for Electrical Safety

Whether you’re installing new panels, upgrading circuits, or maintaining high-voltage systems, durable and compliant electrical panel labels are essential for reducing risk and supporting long-term performance.

Electrical labeling demands materials built to last, and a process designed for efficiency. DuraLabel Premium Vinyl Label Stock provides a tough-tested solution for creating clear, long-lasting electrical panel labels, arc flash warnings, conduit markers, and voltage identifiers. Resistant to heat, moisture, and abrasion, these labels meet both OSHA electrical safety and NFPA 70E labeling standards.

With the DuraLabel Toro® Max Industrial Sign and Label System—a portable, all-in-one printer—teams can quickly produce compliant electrical labels on demand. From panel circuit IDs and arc flash warnings to voltage hazard markers and lockout/tagout instructions, Toro Max makes it simple to create exactly what your safety program requires, right at the job site.

Want to strengthen OSHA electrical safety compliance and meet NFPA 70E requirements? Download DuraLabel’s free Electrical Safety Quick Start Guide for proven strategies to label panels, conduit, and other critical equipment. Call 1-888-902-2148 to connect with a safety and efficiency expert today.

Read Next:

OSHA Signs Regulations and Compliance: Everything You Need to Know

The Importance of Labeling for Safe Compliant Electrical Installations

Related Resources

From Flash to Ash: Understanding Arc Flash Hazards and Prevention

What is Arc Flash? When it comes to electrical safety, arc flash is one of the most dangerous—and most ...

Read

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA’s Standard for Electrical Safety in the Workplace, outlines specific ...

Read

Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary? An arc flash protection boundary defines the minimum safe distance ...

Read.png)

.webp)