Floor Marking 101

Companies around the world, from major manufacturers down to your local grocery store, all share a common struggle: efficiently managing the movement of products and people. Business may slow down because storage isn't organized, or forklift drivers aren't sure which way to go. Every company could benefit from better organization, workflow, and safety. Enter floor marking.

Floor marking uses visual signals, such as lines, applied directly on the floor to provide information about a given area. Often, floor marking is used to identify aisles, walkways, or other spaces in warehouses and other industrial workplaces. Using specialized floor tape, paint, or even lighting systems, effective floor marking can enhance safety, streamline logistics, and improve organizational efficiency.

Floor Marking Requirements

OSHA's general standard for workplace floors is 29 CFR 1910.22, titled "Walking and Working Surfaces." The regulation requires these surfaces to be inspected periodically, and kept clean, safe, and accessible. Additionally, where mechanical equipment such as forklifts are used, OSHA's regulations for materials handling (in 1910.176) come into play. These rules require that safe clearances must be maintained, and permanent aisles and passageways must be appropriately marked.

These regulations don't specifically require floor tape, painted lines, or other forms of floor marking; the rules are written to focus on the goal, rather than the method used to achieve it. However, floor marking can be an excellent way to move toward each of the goals laid out in the OSHA regulations. High-quality floor marking tape is cost-effective, highly visible, and withstands the abuse of warehouse traffic.

Applications for Floor Marking

While safety is a clear goal for floor marking, the same process can also be used to meet other important business needs. It can help facilities:

- Indicate where inventory should be stored

- Define loading and unloading areas for inventory

- Mark aisles, pathways, and hazardous areas

- Help visitors find their way around unfamiliar areas

- Direct the flow of traffic within the facility

Companies are increasingly viewing floor marking as a component of the 5S lean manufacturing methodology. Essentially, it helps the Set in Order step. Everything is organized and has its place, from heavy machinery to garbage cans. Floor marking can cordon off these areas, or show employees where to find them.

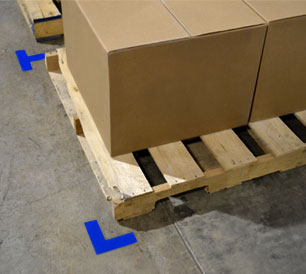

While large companies may have more warehouse traffic, even small companies may have complex and confusing warehouse layouts. Both can benefit from floor marking to alleviate potential bottlenecks. For example, floor marking tape can clearly mark areas for pallets. If you can't tell where to put the pallets, you're wasting time, taking up valuable space, and compromising safety. With floor marking, you can organize the pallets based on their content or shipping destination.

Floor Marking Tape Benefits

Applying floor marking tape is quick and cost-effective, compared to painting floors. Stenciling or painting on a floor is messy. Basic paints wear off quickly under foot traffic, and tougher epoxy or enamel paints release fumes during application and curing that can require temporary closure of part of a facility. Preparation for painting, and waiting for paint to dry, can also impact productivity. Floor marking, by contrast, produces no fumes and needs no time to dry or cure.

All floor marking tape is not created equal. For heavy duty facility traffic, DuraLabel has introduced a family of floor marking supplies that can take daily punishment from vehicles, enhance safety communication, and direct people to exits and entrances.

How to Apply Floor Marking Tape

It's easy to apply floor marking tape, whether in a small facility or a large one. Follow this simple process:

- Prepare the floor surface by cleaning with soap and water

- Determine areas to be sectioned off including aisles, electrical boxes, storage areas, eye wash stations, fire extinguishers, garbage cans, recycling stations

- Measure area widths

- Determine floor marking tape colors and other supplies based on inventory, traffic flow patterns, areas needing specific boundaries for safety, height, available light in the facility and corporate logos

- Load up applicator with floor marking tape

- Apply tape

- Clean with damp mop

DuraLabel can help make the application process quick and easy. Facilities can rent or purchase the PathFinder Floor Tape Applicator (qualifying PathFinder purchases include a free rental), which ensures smooth application and guarantees an effective adhesive bond with a heavy-duty roller system for added pressure.

Creating Printed Floor Signs

One indispensable tool for any warehouse, facility or supply chain manager is a thermal transfer printer to generate signs and labels that complement floor marking supplies. The DuraLabel line of printers from DuraLabel can even allow users to create custom-printed floor marking, as well as signs and labels for safety, efficiency, wayfinding and other applications. Printable Premium Vinyl Supplies are the perfect tool for customized messages that supplement an overall floor marking scheme.

While industrial and warehouse environments are likely the most common floor marking applications, forward-thinking facility managers can also leverage floor marking strategies beyond tried and true environments.

Related Resources

What is Floor Marking?

How Does Floor Marking Improve Workplace Safety? Floor marking improves workplace safety by clearly defining ...

Read

A Quick Guide to Floor Marking Products

Why are Floor Marking Solutions Important? Floor marking solutions help safety managers and facility teams ...

Read

Why OSHA Required Floor Marking Fails in Summer

Why Does Floor Marking Tape Fail More Often in Summer? Floor marking tape fails more frequently in summer ...

Read.png)

%20(1).webp)