What is Floor Marking?

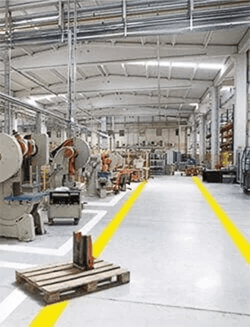

Visual safety communication takes many forms in the workplace. Beyond just signs and labels, floor marking is a valuable tool to communicate hazards, mark exit routes, and ensure traffic safety. Warehouse floor marking involves the use of colored lines, shapes, and symbols on the floor to convey important information in the workplace. This wayfinding practice is particularly common in industrial settings, warehouses, and manufacturing facilities.

Common Uses of Floor Marking for Workplace Safety

Pathways and Aisles: Clearly marked pathways and aisles provide proper wayfinding that guides the movement of people, vehicles, and materials. Different colors may be used to designate specific areas or indicate the flow of traffic. These visual factory tools also support OSHA workplace safety practices by ensuring organized movement through shared spaces.

Hazardous Areas: Floor marking tape can highlight hazxardous zones, such as areas where there is a risk of falling objects, exposure to chemicals, or other potential dangers. This helps employees stay aware of potential risks and take necessary precautions by adhering to floor marking regulations.

Emergency Exits and Escape Routes: Marked floor paths leading to emergency exits and escape routes assist in quick and safe evacuation during emergencies. This is crucial for the well-being of employees in case of fire, natural disasters, or other urgent situations.

Storage Areas: Marking designated areas for storing materials and equipment ensures organized and safe storage practices. A variety of colors may be used to distinguish between different types of materials or storage requirements while meeting OSHA floor marking guidelines.

Workstations and Equipment Placement: Industrial floor marking can be used to outline the boundaries of individual workstations or the proper placement of equipment. This helps maintain clear pathways and prevent overcrowding in specific areas while aligning with 5S marking standards.

Safety and Caution Signs: Floor marking can complement other safety signage by reinforcing important messages. For example, safety floor markings with the word "CAUTION" can alert employees to be mindful of potential hazards.

Spill Response and Cleanup Stations: Floor markings can indicate the location of spill response kits and cleanup stations. This ensures quick access in the event of spills or leaks of hazardous materials. Clear markings help employees respond quickly and effectively, which minimizes the risk of accidents or environmental contamination.

It's important to establish consistent and clear communication about the meaning of different floor markings within the workplace. Training employees on the significance of various floor markings, regularly maintaining the markings, and staying informed of OSHA floor marking guidelines promotes a safer work environment and improves OSHA compliance with 5S systemsOSHA Requirements for Floor Marking

OSHA requires that all walking and working surfaces are inspected periodically, and kept clean, safe, and accessible (29 CFR §1910.22). Where mechanical equipment such as forklifts are used, safe clearances must be maintained, and permanent aisles and passageways must be appropriately marked (§1910.176). Industrial floor marking is a convenient and inexpensive step toward meeting these requirements and maintaining OSHA workplace safety practices.

Floor Marking Color Regulations

OSHA’s general color code for marking hazards, described in 29 CFR §1910.144, only uses two different colors: red for “Danger” (marking severe hazards), and yellow for “Caution” (marking less severe hazards).

The American National Standards Institute (ANSI) standard Z535 uses red for “Danger” and yellow for “Caution,” just like the OSHA color code. They also use orange for “Warning” (for hazards that are not as extreme as “Danger,” but are more serious than “Caution” might imply). The ANSI Z535 standard adds green for safety messages and information, and blue for notices that provide other, facility-specific information. While these color assignments are described as used on signs and labels, the same general colors can be used for other needs, such as meeting the floor marking regulations for industrial environments.

Improve Workplace Safety with Floor Marking

Floor marking serves as a crucial element in enhancing workplace safety and understanding. Consider the following examples of how industrial floor marking can be effectively utilized to promote safety in various aspects of a work environment and comply with OSHA floor marking standards:

Traffic Routes:

Many people in the United States utilize motor vehicles, as they often provide the quickest and most affordable form of mobility. It has been the National Highway Traffic Safety Administration’s mission to create avenues that will save lives, prevent injuries, and reduce economic costs. These costs can be a result of road traffic crashes, through education, research, safety standards, or enforcement.

The Department of Transportation collected data based on findings created by the Fatality Analysis Reporting System (FARS) and non-fatal motor vehicle traffic crashes from the National Automotive Sampling System (NASS), General Estimates System (GES), and Crash Report Sampling System (CRSS). Based on the information gathered for the 2021 year:

- One person was killed every 12 minutes

- 5 people are injured every minute in traffic crashes

- The fatality rate per 100 million vehicle miles traveled (VMT) increased from 79 in 2020 to 80 in 2021

Clear and distinct pathways for both pedestrian and vehicular traffic are paramount for daily operations and wayfinding, especially during emergencies. Implementing floor marking solutions plays a vital role in delineating these pathways and enhancing overall traffic safety in alignment with OSHA workplace safety practices.

Forklifts have been the culprit of numerous workplace incidents in 2022. The Bureau of Labor and Statistics reported from 2021–2022 that forklift accidents resulted in:

- 73 work-related deaths

- 24,960 Days away from work, job restrictions, or transfer (DART) cases

The prevalence of workplace fatalities resulting from forklift collisions underscores the importance of well-marked traffic routes. Effective warehouse floor marking should be easily comprehensible, letting everyone navigate safely. Employ floor tape to:

- Distinguish separate lanes for vehicle and pedestrian traffic.

- Identify intersections and blind spots around corners.

- Highlight safe pathways to exits, stairwells, aisles, and emergency equipment, even in low-light conditions.

Hazardous Areas:

Four types of hazards occur in the workplace, chemical, biological, ergonomic, and physical hazards. Out of the four hazards, physical hazards, like slips, trips, and falls are the most common. The Bureau of Labor and Statistics, reported in 2022:

- 5,486 fatal work injuries

- 5.7 % increase from 5,190 in 2021

- The fatal work injury rate was up from 3.6 per 100,000 in 2021

Employers bear the responsibility of safeguarding workers from occupational hazards. Preventing potential accidents can be achieved through installing traction, safety messages, and hazard-striped boundaries with safety floor marking tape. Enhance safety by marking:

- Pedestrian pathways and boundaries in high-traffic areas around moving machinery, equipment, loading docks, and electrical panels.

- PPE-required work areas with hazards and entry requirements clearly marked.

- Slippery areas such as washdown stations, stairs, and handrails.

Product & Material Storage:

Exposure to hazardous chemicals poses a significant risk to any work environment. According to the National Institute of Environmental Health Sciences (NIH), chemical exposure leads to 50,000 workplace-related illnesses each year.

Clearly marked areas for chemical storage, spill containment, and personal protective equipment (PPE) zones help mitigate the risk of accidental exposure and contamination while meeting floor marking regulations. By marking storage areas for products and materials, it minimizes confusion and optimizes efficiency. In line with 5S floor marking and lean strategies, color-coding facilitates communication about the designated locations for materials, contributing to overall organization. Here are five ways floor marking can be beneficial for product and material storage:

- Organization: Floor marking tape can designate specific areas for different types of products or materials by using different colors and patterns to organize. This process helps improve efficiency in storage facilities.

- Safety: Aisles, walkways, and storage zones that are marked help prevent accidents by ensuring that employees are aware of when it’s safe to walk and where materials should be stored.

- Space optimization: Floor markings can indicate where items should be placed, ensuring that space is utilized efficiently and that there is a clear plan for storage, reducing clutter and congestion.

- Inventory management: Inventory management will become easier when warehouse floor marking is used to designate locations for specific products and materials. It will allow for quicker identification and retrieval of items when they are needed.

- Compliance: Based on some safety regulations and standards, floor marking is required in some industries to avoid fines or penalties.

Machinery & Equipment:

The third leading cause of workplace fatalities is injuries sustained from contact with objects and equipment.

- 738 fatalities

- 780,690 Days of job transfer or job restrictions cases in 2021-2022

- 450,050 cases were reported for days away from work

Industrial floor marking can be applied to many areas, such as tool boards, parking spaces for forklifts, and drawers. A couple of ways to safeguard workers from injury is to label the machinery and equipment and mark the floor with designated locations. This ensures efficient access to tools, all while helping to prevent clutter and reduce the risk of injuries. Here are some areas where floor marking can improve safety in your facility:

- Hazard identification: Mark dangerous zones clearly to support OSHA compliance with 5S systems.

- Emergency routes: Use reflective tape to highlight paths to exits in dark or smoke-filled conditions.

- Equipment placement: Designate safe zones for machines to avoid collisions.

- Visual warnings: Use high-visibility floor tape to emphasize caution around specific work areas.

Floor Marking & Wayfinding:

Creating a visual workplace involves incorporating labels, signs, and other visible cues to facilitate understanding of the operational aspects of an area.

This includes instructional placards on walls and machinery, signs with important reminders, equipment labels, and inventory management tags. Some areas may benefit from reflective tape for an extra measure of safety. A visual workplace, including warehouse floor marking, is integral to comprehensive 5S marking standards. Floor marking aligns with a broader organizational philosophy known as wayfinding, essential for orienting individuals in physical spaces and guiding them from one location to another. Wayfinding principles encompass four stages:

- Orientation: Determining one's location in relation to nearby objects.

- Route Decision: Selecting a course of direction to a specific destination.

- Route Monitoring: Ensuring the selected route leads toward the intended destination.

- Destination Recognition: Confirming when the final destination has been reached.

Floor Marking Color Patterns

While every facility will have its own plan, there are certain colors and patterns that have common uses in industrial floor marking deployment. Using colors that catch your eye ensures that any high visibility tape rarely goes unnoticed. Make sure to train your employees on the specific colors and patterns used in your facility to meet both 5S marking standards and OSHA floor marking expectations.

YELLOW - Commonly used for pedestrian and equipment traffic lanes, aisles, and pathways.

WHITE - Used for general production to border machines, racks, workstations, and equipment.

RED - Often used as a boundary for red tag areas, scrap, and defective inventory.

ORANGE - For holding materials or products, often for inspection.

BLACK/GREEN/BLUE/PURPLE - Materials management stages including raw materials, finished goods, and in-process manufacturing.

RED/WHITE STRIPING - Identifies areas that need to be kept clear for safety such as equipment operations, electrical panels, and exits.

BLACK/WHITE STRIPING - Identifies areas that must be kept clear for operations and workflow.

BLACK/YELLOW STRIPING - Use in areas that present health hazards and require extra caution.

Floor Marking Solutions to Find Your Path to Safety

Warehouse floor marking is an indispensable component of a safe and organized workplace, providing visual cues that guide and protect employees. To implement an effective floor marking strategy, it's essential to utilize high-quality materials and equipment. DuraLabel offers a comprehensive line of floor tapes, signs, and industrial label printers that are specifically designed to meet the demands of diverse work environments.

DuraLabel's floor marking solutions not only enhance safety but also contribute to the overall efficiency and organization of your workspace. Take the next step in elevating your workplace safety standards by giving us a call today at 1-888-695-5670, and one of our safety experts can guide you through the process.

DuraLabel’s free Floor Marking Quick Start Guide not only helps facilities create safe pathways for pedestrians and vehicular traffic but also guides workers to the tools they need. Download your free copy today.

Learn more about 5S, including 5S floor marking. DuraLabel’s free 5S System Best Practice Guide helps build a 5S system that can be implemented in your environment. The guide can also help set facility standards, as well as improve safety and efficiency.

Read Next:

Shine a Light on Safety: LED Floor Marking Improves Wayfinding

Related Resources

5S Floor Marking: Organization & Safety Fundamentals for Your Facility

What is 5S floor marking? 5S floor marking helps communicate workplace organization, improve safety, and ...

Read

A Quick Guide to Floor Marking Products

Why are Floor Marking Solutions Important? Floor marking solutions help safety managers and facility teams ...

Read

Floor Marking 101

Companies around the world, from major manufacturers down to your local grocery store, all share a common ...

Read.png)

%20(1).webp)