FOCUS PDCA: Your Guide to Systematic Process Improvement

FOCUS PDCA is a management method, developed in the healthcare industry, used to improve processes. Created by the Hospital Corporation of America (HCA), it is a systematic process improvement method. Through FOCUS PDCA, a knowledge of how a process is currently performing to meet customer needs and expectations is used to plan and test process changes. FOCUS PDCA is an extension of the Deming or Shewhart Cycle which includes Plan-Do-Check-Act. The HCA FOCUS piece precedes the PDCA with a five-part plan:

- Find a process to improve

- Organize to improve the process

- Clarify current knowledge of the process

- Understand the source of process variation

- Select the process improvement

Although created for the medical industry, FOCUS PDCA can be used by any type of organization. The FOCUS portion identifies the area needing improvement, brings together a team that is capable of achieving improvement, and selects a solution. The PDCA portion identifies what needs to be done to implement the solution, makes the necessary changes, and verifies that the desired result has been achieved.

Why Use FOCUS PDCA?

The FOCUS PDCA method works well in a number of situations, and in particular when there is a highly technical or complex work environment or task. The advantages include:

- It does not require in-depth expertise, even when working with highly technical or scientific processes.

- A wide range of people can be involved, bringing additional expertise to solving the problem.

- The method can be learned quickly.

- It provides a framework that guides improvement efforts.

- It keeps everyone focused on the area and problem being addressed.

- It clarifies the goal of the project for everyone involved.

- There is accountability for completing tasks.

- It supports a culture of continuous improvement.

Changes and success are based on measurable data and observations.

The Steps Defined by FOCUS PDCA

The FOCUS PDCA acronym describes the basic components of the improvement process. These are:

Find a Process to Improve

In some cases, the problem may be obvious. A process may not be meeting quality goals, or environmental emissions may be too high. However, in other cases, there may not be a readily apparent need for improvement. For example, a Failure Mode and Effect Analysis may reveal a previously unknown problem. The guiding principle of FOCUS PDCA should be to bring all processes fully into alignment with the strategic goals of the organization.

Organize a Team

The team should be composed of people who understand the process, but they do not need to be experts. The team should include those who are closest to the process, such as those who operate and maintain it. It is also worthwhile to include those who provide inputs to the process, and those who receive its outputs - that is, the people "upstream" and "downstream" of the process.

Clarify the Current Understanding of the Process

Collect data and information about the process. This may be done through physical measurements, but it should also include talking with those who are involved with the process. Get the answers to the six basic questions: who, what, where, when, why, and how.

Understand Variation in the Process

Every process includes variation, and some variation is usually acceptable. When variation interrupts the normal flow of work, it may be a symptom of problems in the process, and often causes other problems as well. In this step, the question "why" is asked to find the cause of variation. This is sometimes called "Five Whys" - the general principle is to ask "why" a sufficient number of times (often five) to identify the real cause of the variation.

Select a Strategy for Improvement

This step may involve brainstorming or other methods of developing ideas. Then, based on what was learned in the previous two steps, the best solution is selected. Keep in mind that the solution must be in alignment with the overall organization's strategy, it must add value for the final customer, and it must be both technically and financially feasible.

The final four steps are PDCA, a modified version of the Deming Cycle. It is a continuous process used to improve a process or system.

Plan

In a traditional PDCA the "Plan" step is where the problem is defined and a solution developed. In FOCUS PDCA, that has already been accomplished. Instead, the "Plan" step is where the implementation of the solution begins. Based on the solution identified in the final step of FOCUS, a plan for implementing that solution is developed. The plan specifies what will be done, how it will be done, when it will be done, and who is responsible for each task needed to complete the necessary changes. In addition, a means for data collection and measuring success is established.

Do

If it was not done as a part of FOCUS, data must be collected to characterize the condition of the process before changes are made. Then the required changes are made - that is, the plan is implemented.

Check

Did the changes have the desired result? Data is collected, the process is observed, and the changes are evaluated by comparing the actual results with the desired results. If the results are not as desired, then the previous steps are reviewed. This includes going back to the beginning to be sure the problem definition was correct, and the root cause was accurately identified.

Act

The final step is to take the steps necessary to maintain the improvement. For example, the changes should be incorporated into the standards governing the process. In addition, a means of monitoring the process or system should be established so that variations from the new normal can be readily detected.

The purpose of FOCUS PDCA is to provide a structure that guides the process of problem-solving and process improvement. By using this approach, a comprehensive analysis, response, action plan, and feedback loop is established to ensure success.

Keeping people safe during the FOCUS PDCA process, and after changes have been made, is a top priority. In many cases, this means identifying safe areas and using tools such as floor marking to keep people separate from moving machinery and vehicles. You can learn more about effective, durable floor marking with a free Floor Marking Best Practice Guide.

Related Resources

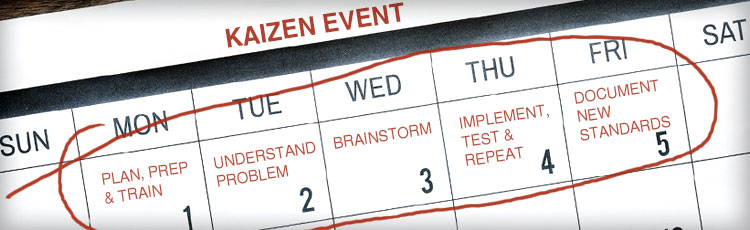

Kaizen Event: Driving Focused Continuous Improvement

What Is a Kaizen Event and How Does It Improve Lean Processes? AKaizen eventis a focused, short-term effort ...

Read

What Is Kaizen? - The Benefits of Kaizen Explained

What is Kaizen? Kaizenis a Japanese philosophy that meanscontinuous improvement with Kaizen. It focuses on ...

Read

Kaizen Getting Started

There is more to implementing Kaizen than we can include on a single web page. However, the following serves ...

Read.png)