How to Meet IIAR Standards for Ammonia Pipe Marking

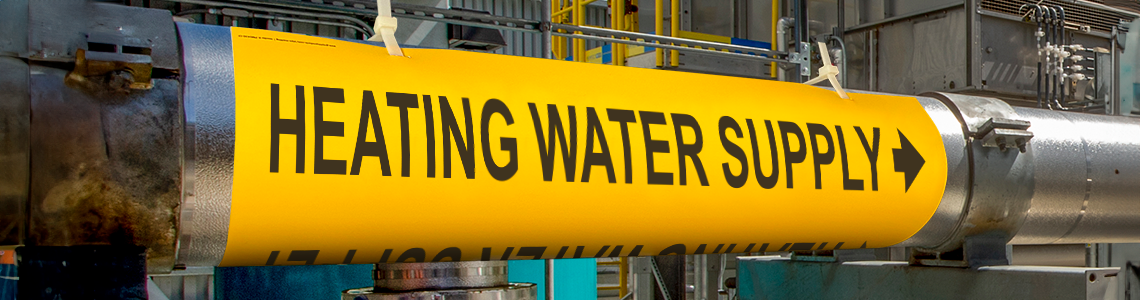

For safe operations and maintenance, its important employees know what's inside the pipes they're working around to prevent accidental exposure to hazards. If contents in a pipe may be hazardous, that information should be clearly communicated as a matter of human safety.

Recently, a multinational American corporation in the food industry agreed to pay a civil penalty of $3.95 million for eight separate incidents that occurred over the span of four years. The accidents were due to the accidental release of dangerous levels of anhydrous ammonia in several facilities causing property damage, multiple injuries, and one fatality.

The Environmental Protection Agency (EPA) says ammonia refrigeration facilities have higher accident rates than other processes, which puts a major focus on ensuring safety practices are in place to protect employees, first responders, and communities located near processing facilities from the threat of chemical releases. Luckily, there are accident prevention steps and systems facilities can implement to keep workers safe and aware of the presence of ammonia.

IIAR Bulletin 114

Ammonia is number two among the top five chemicals associated with injury (from 1999-2008) according to the CDC. The presence of toxic ammonia can cause harmful health effects ranging from irritation to severe respiratory injuries and even death at higher concentrations.

To improve the safety of ammonia refrigeration piping and system components, the International Institute of Ammonia Refrigeration (IIAR) has a guideline for labeling them: Bulletin No. 114. The purpose and requirements stem from ANSI/ASME A13.1 to provide consistency with general pipe marking standards.

Identifying ammonia refrigeration piping and components helps to:

- Promote safety because personnel are aware of potentially hazardous contents of pipes

- Simplify maintenance so workers can easily follow the piping system

- Quickly communicate vital information to emergency personnel

How to Make an Ammonia Pipe Marking Label

The IIAR label standard includes two different types of labels that make up a complete ammonia pipe marking system. The label that goes on the pipe itself consists of five parts:

.webp)

Five-Part Ammonia Label

- Piping Abbreviation: Identify the name of the pipe's role in the system (such as "OD" for Oil Drain).

- Physical State: Communicate the physical state of the contents at that point in the pipe.

- Pipe Contents: Clearly print "AMMONIA" in the middle of the label.

- Pressure Level: Communicate whether the internal pressure of the pipe is high or low.

- Direction of Flow: Indicate the direction the contents flow in the pipe with a directional arrow.

Two-Part System Component Label

In addition to five-part labels, each piece of equipment in an ammonia refrigeration system may also be labeled. This label consists of two sections:

- Name of the system component: Identify the equipment name with its abbreviation.

- Pressure level: Communicate whether the internal pressure of the pipe is high or low.

Include a reference chart that fully explains the ammonia refrigeration piping and component identification markers, including piping abbreviations, in areas where people can see them. For a visual, step-by-step breakdown of an ammonia label, download Duralabel' Ammonia Pipe Marking Reference Guide.

In addition to the labels themselves, the IIAR also suggests a piping color scheme to help aid in training and safety efforts. A color-coding system can help make pipes and pressure relief valves quicker to identify and can help improve response time in an emergency situation. The colors may be applied using paint over the length of the pipe or as bands of color. If you decide to implement a piping color-code system, post a legend or key to describe the color scheme in place where personnel can easily see it.

To enhance safety, post ammonia placards that communicate the National Fire Protection Association (NFPA) 704 anhydrous ammonia diamond and general ammonia safety signs to alert personnel of areas where ammonia is present. Protect refrigeration equipment like pipes, valves, and tanks by drawing attention to barriers, like bollards using PathFinder reflective tape. This can help alert personnel to prevent forklifts and other machinery from colliding and potentially damaging components of ammonia refrigeration systems.

A pipe marking system is about more than just meeting regulatory requirements, it also helps to strengthen an overall safety program.

Pipe Marking Standards: Canada

The safety of piping systems is a concern in facilities worldwide. This is why a broad, voluntary general pipe marking standard was created in Canada by the Canadian General Standards Board (CGSB): CAN/CGSB 24.3-92. However, in June 2016, the governmental organization withdrew the archaic standard originally established in 1992. The label guidelines are similar to ANSI A13.1:

- A recommended color-code

- Display of legible information

- Clearly visible label positioning

- Pictograms to indicate the type of hazards that may be present in the pipe

Canadian workplaces may follow ANSI A13.1 and IIAR ammonia pipe marking standards as a guideline for a holistic pipe marking system. Having some kind of pipe marking system in place will help increase overall safety, reduce the chances of error, simplify emergency procedures, and minimize hazards.

Does your pipe marking system need some fine tuning? Find out how to implement or update a general pipe marking system with Graphic Product's Best Practice Guide to Pipe Marking. This guide outlines industry standards, explains different types of pipe marking in the field with visual charts, and solutions to help streamline the labeling process.

Solutions for Ammonia System Labeling

To help accomplish all of your ammonia pipe labeling tasks, consider a DuraLabel Toro Ammonia Pipe Marking Kit. Mass produce pipe marking labels for your entire facility with the multipurpose Toro printer with durable supplies to create custom pipe marking labels. Toro uses supplies that are made to endure their environment and are engineered to resist fading from UV light, moisture, and most chemicals to provide lasting durability. DuraLabel Premium Vinyl Tape is a perfect supply for pipe marking and is available in a wide variety of colors to meet your specific needs, both indoors and outdoors.

Simplify the labeling process with preinstalled label design software that comes on nearly any DuraLabel industrial label and sign printer. Just use the built-in pipe marking module to create IIAR-style pipe and component markers in a snap.

Download our free Ammonia Pipe Marking Chart below to keep a handy reference of standards near your labeling printer to ensure your labels are always compliant.

Related Resources

BS 1710 British Standard Pipe Marking

British Standard 1710 (BS 1710) provides a robust framework that fulfills the pipe marking requirements set ...

Read

Safety that Sticks: Using Pipe Labels for Every Size and Type of Pipe

Proper use of pipe labels in industrial settings is essential for safety, compliance, and operational ...

Read

How to Get Started with Pipe Marking and Labeling

Pipe marking quickly communicates information about a pipe and its contents, improving overall workplace ...

Read.png)