Understanding the ASME A13.1 Standard for Enhanced Pipe Labeling

Natural gas pipe labeled with an ASME A13.1-compliant yellow marker and flow arrows, demonstrating standardized industrial pipe identification for safety labeling and maintenance signage.

What is the ASME A13.1 Standard for Pipe Labeling?

The American National Standards Institute (ANSI) A13.1 standard provides a widely recognized system for identifying pipe contents through standardized colors, text, and formatting. Adopted across many industries, this ANSI/ASME guideline improves workplace safety, supports hazard communication, and helps facilities implement consistent, compliant pipe marking programs.

The sections below break down what ASME A13.1 requires, how color schemes and label formats are structured, where the standard applies, and how facilities can implement effective pipe identification systems.

- The purpose and scope of ASME A13.1

- Required elements of compliant pipe labels

- Color classifications for hazardous and nonhazardous fluids

- Size, visibility, and placement guidelines

- How ASME A13.1 aligns with OSHA expectations

- Common pipe labeling mistakes facilities make

- Best practices for implementing standardized pipe marking

- Resources that support compliant pipe labeling programs

Clear pipe identification is not just a visual upgrade. It is a frontline safety control. Understanding ASME A13.1 is the first step toward building a safer and more organized facility.

History of ANSI and ASME A13.1

ANSI/ASME A13.1 is the broadest and most common recommendation for OSHA pipe marking in the United States. The standard has been revised over time, with the biggest change in 2007 when the old ANSI pipe labeling standard was combined with recommendations from the American Society of Mechanical Engineers (ASME). As a result of the cooperation between the two groups, the new standard has been called "ANSI/ASME A13.1," or "ASME A13.1."

The 2007 edition dramatically changed the pipe marking color codes to identify the type of hazard posed by a pipe's contents, rather than only showing whether the contents were hazardous. Additional colors were specified for user definition, allowing flexibility for unique situations. The latest edition, which was in 2023, includes minor revisions. The scope and all definitions were revised, and the Legend section was expanded. Both the Color section and Table 4.2-1, “Designation of Colors,” were updated. ASME A13.1 has been changed from a periodic-maintenance to a continuous-maintenance Standard. New figures were added: Figure 4.1-1, “Flow Direction to the Right”; Figure 4.1-2, “Flow in Both Directions (Double-Headed Arrow)”; and Figure 4.1-3, “Flow in Both Directions (Arrows Pointed in Opposite Directions).” The former Figure 4.1-1 is now designated as Figure 4.1-4, “GHS Pictograms.”

When a pipe's contents or use could pose a hazard to workers, pipe marking requirements for contractors may be a necessary step for workplace safety, and missing pipe identification labels can put your facility at risk of citations under the Occupational Safety and Health Administration's (OSHA) General Duty Clause. While OSHA requires certain industries to follow the ANSI pipe labeling standard, other facilities are better served with a different system; consider the pipe labeling standards that will apply to your facility's type and location. Check with your local authorities before beginning a pipe label project to ensure you're fully complying with the law.

ASME A13.1 Pipe Label Requirements & Components

Under the ASME A13.1 approach to pipe marking, there are five key elements to an effective pipe identification label:

- Bold text to identify the pipe's contents by name (Additional details, such as temperature or pressure, may also appear).

- Color coding to communicate the general category of the contents.

- Flow direction arrows to show which direction the pipe's contents flow.

- Label sizing to ensure the custom pipe labels are visible and legible.

- Label placement for clear viewing from a normal approach.

For additional details about these five elements, see our Best Practice Guide to Pipe Marking.

Pipe Marking Guide to the ANSI/ASME A13.1

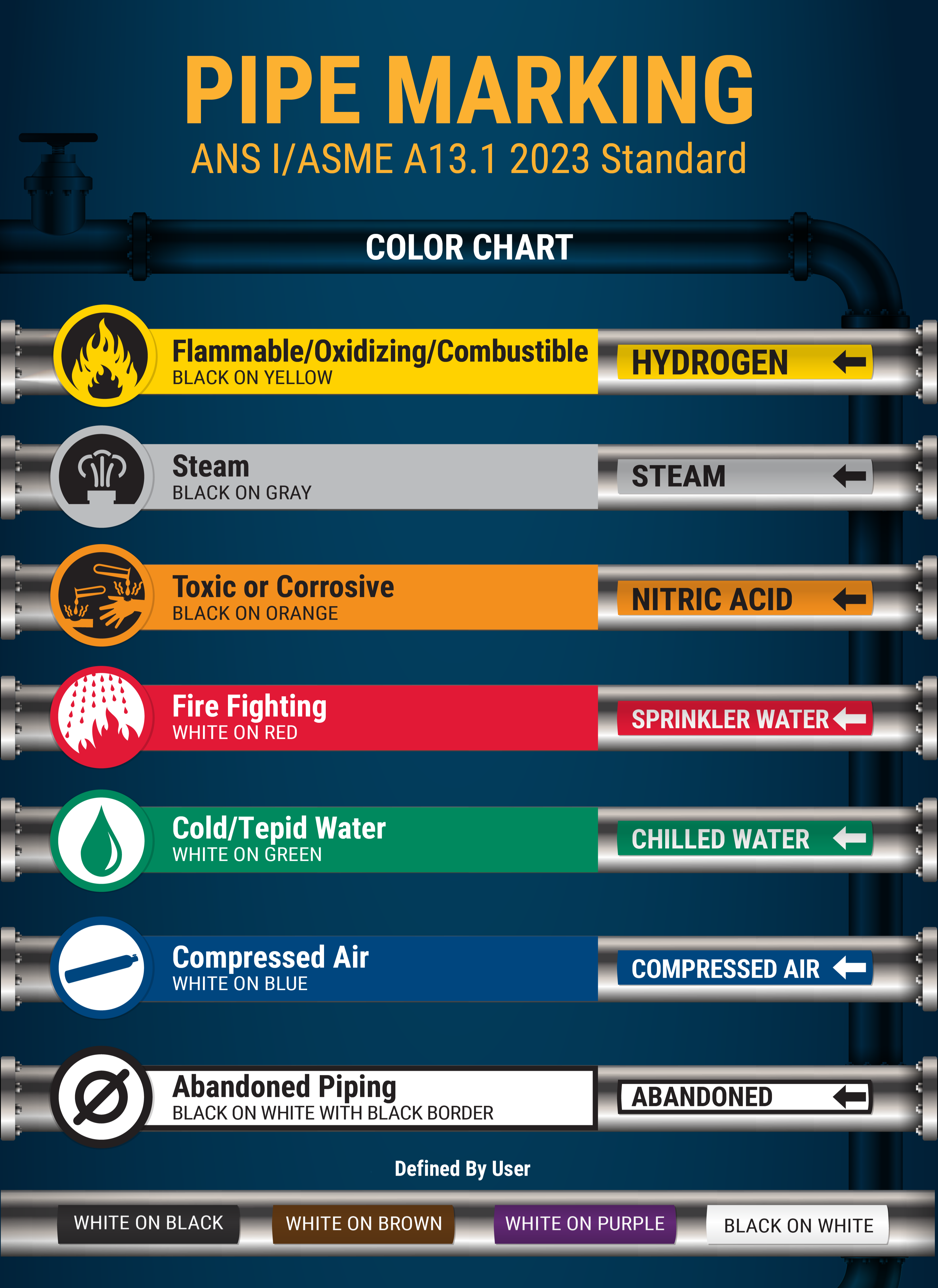

ASME A13.1 Pipe Marking Color Code

ASME A13.1 recommends a pipe marking color code designed to quickly alert workers to potential hazards. The pipe marking standards consists of six predefined colors to identify broad types of pipe contents. There are also four user-defined combinations that can be defined separately by each facility using the standard.

The most hazardous feature of the pipe contents should determine the color scheme used:

Each category uses a solid color for the pipe label background, which may also be used to color the entire pipe if desired. The text must appear in a contrasting color. If pipes fall under more than one category, there are two common approaches for choosing the color: identify one of the hazard types as more significant, and use that categorization, or use one of the user-defined colors to identify that particular type of pipe in the facility.

Clearly document the ANSI pipe marking color codes in use, and train workers to recognize and understand it. This is especially important in situations where a highly specialized piping system makes the common ANSI color code less effective. For example, pipes in hospitals often carry a variety of compressed gases; some are for patients to breathe, while others are for operating equipment, and others are part of an anesthetic system. Confusion across these types of pipes could be dangerous, or even fatal. As a result, hospitals typically follow a more specialized pipe labeling standards system.

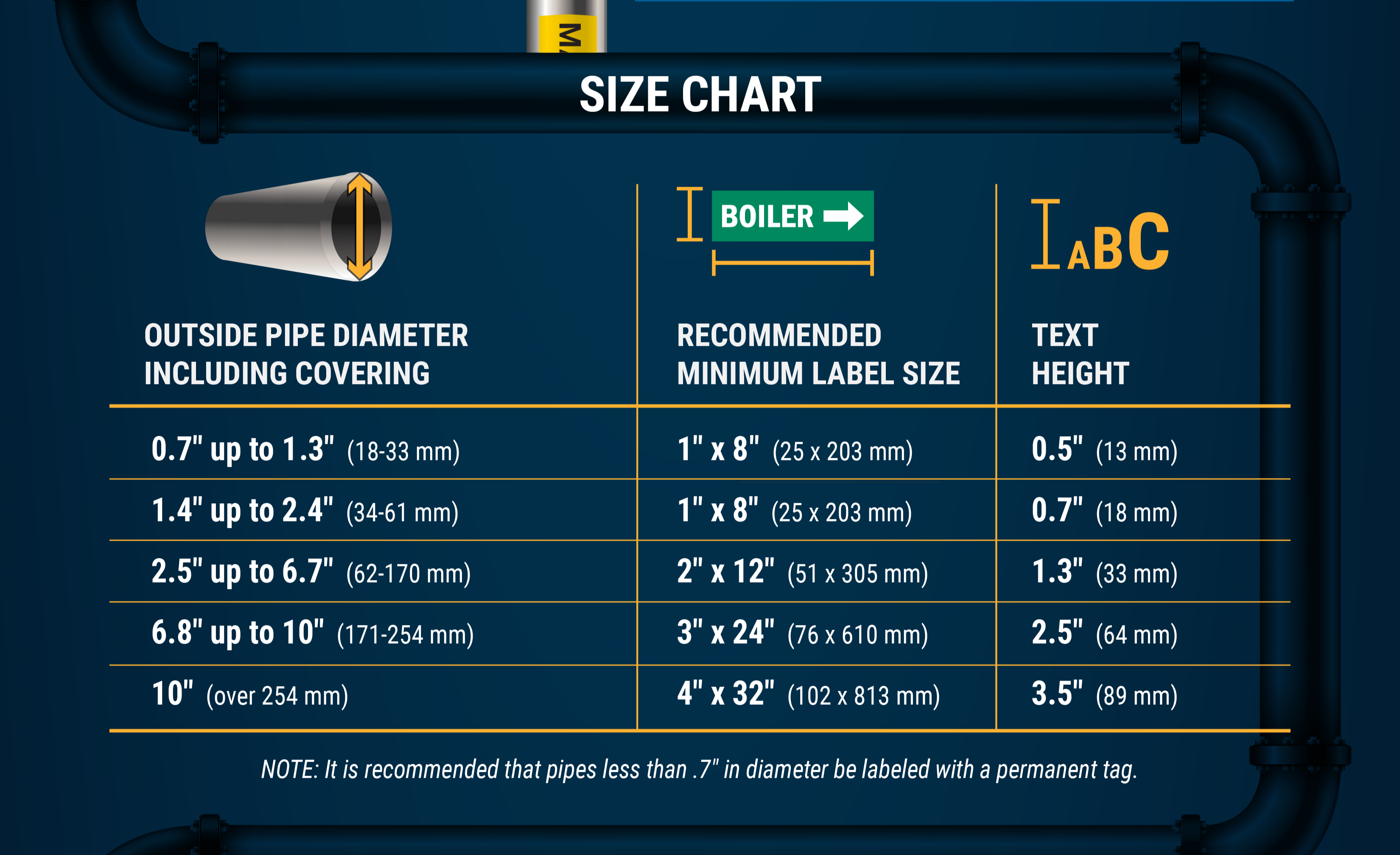

ASME A13.1 pipe marking size chart infographic showing outside pipe diameter ranges with recommended minimum label dimensions and text heights for compliant industrial pipe identification and safety labeling.

Pipe Label Size

The diameter of the pipe will determine the appropriate pipe identification label and text size. A size chart can help any facility understand the appropriate label for their specific piping system. Determine the pipe label sizes you need for your pipes by identifying the outside pipe diameter.

Pipe Label Placement

Pipe marker labels must always be clearly visible from the normal angle of approach. For example, if the pipe is overhead, apply the label below the centerline. If the pipe is below eye level, apply the label above the centerline. Additional recommendations for label placement:

- Near all valves and flanges.

- Adjacent to changes in direction.

- Both sides of floor/wall penetrations.

- At regular intervals on straight runs of pipe; at least one label every 50 feet (about 15 meters) throughout the piping run.

When applying custom pipe labels directly to a pipe or covering is not possible, apply valve tags or stand-off pipe marking signs since they're both ideal for small pipes, providing a durable base for OSHA pipe marking. If pipes are difficult to label or tend to get greasy and dirty, pipe grabber sleeves will protect labels and prevent damage. When you're ready to install your labels and have pipes that are difficult to reach, a pipe marker applicator is a great way to safely and securely apply them without a ladder. Relying on valve tags, grabber sleeves, and other pipe marking accessories can enhance your piping system and will help your labels last for years to come.

ASME A13.1 Pipe Marker Evaluation Checklist

When you're ready to carry out a full pipe marking project, do a walk-through of your facility and take note of the pipe marker labels that are needed. Streamline the process with a handy evaluation checklist. Periodically, repeat a general pipe labeling standards inspection process to ensure labels are intact, legible, and accurate. Always replace any damaged, outdated, or worn labels right away to maintain safety and prevent new hazards.

Streamline Your ASME A13.1 Pipe Labeling Efforts

If you're ready to install or update pipe marking for your entire facility, utilizing a DuraLabel pipe label printer is a convenient and quick way to get started. In addition, you can produce custom pipe identification labels and signs for a variety of other industry labeling requirements. Consider the DuraLabel Toro Max Pipe Marking Kit to ease the pipe labeling process. It contains all the essential pipe labeling standards supplies you'll need at a discounted price.

For smaller jobs, premade pipe markers are perfect for one-off labels, replacement labels, and other small ANSI pipe labeling projects. These pipe marker labels ship to your facility ready to install and are preprinted with all the essential information to make up a standardized pipe label in line with ANSI/ASME A13.1 and the International Institute of Ammonia Refrigeration (IIAR) pipe marking standards.

A great way to learn more about pipe labeling standards with DuraLabel’s free Pipe Marking Quick Start Guide. This guide helps you stay compliant with OSHA and ANSI pipe labeling standards, understand potential hazards in pipes, and adhere to industry-specific regulations. For help creating a reliable labeling system, call 1-888-411-3520 and speak with an expert who can guide you through the process.

Read Next:

How to Meet IIAR Standards for Ammonia Pipe Marking

Facility Safety and Compliance: Utilizing the Right Pipe Markers

Related Resources

.png)

Navigating Pipeline Pathways with Directional Pipe Markers

Directional pipe markers are key when it comes to effectively identifying a facility’s pipe system. These ...

Read

The Dangers of Abandoned Pipes

Whether a pipe contains chemicals, water, or nothing, it's important to know if it's hazardous. ANSI/ASME ...

Read

The Benefits of Pipe Marking

Pipe Marking Benefits Industrial pipe marking is an economical solution to any facility's complex pipe ...

Read.png)