Custom Signage Built Around OSHA ANSI Signs for Safer Workplaces

How Do Slippery When Wet Signs Prevent Common Workplace Injuries?

Slippery When Wet signs prevent common workplace injuries by giving people an immediate visual warning when a floor becomes hazardous. These workplace hazard signs provide immediate visual cues that alert workers and visitors to potentially dangerous walking surfaces.

The sections explain why wet-floor hazards cause so many incidents, what compliant signage requires, and how to reinforce warnings with floor marking:

-

Why slips, trips, and falls remain a top injury risk

-

Where wet-floor hazards show up most often

-

How OSHA and ANSI signs reduce real-time exposure

-

What 29 CFR 1910.145 requires for hazard signage

-

How OSHA floor tape strengthens wet-zone control

The table below summarizes common wet-floor hazards and the visual communication methods used to prevent related injuries.

| Common Wet-Floor Risk | Why It Causes Injuries | Visual Prevention Method |

|---|---|---|

| Slippery surfaces from cleaning or spills | Reduced traction leads to sudden slips and falls | “Slippery When Wet” safety signs |

| Unmarked wet zones | People enter hazardous areas without warning | OSHA/ANSI-compliant warning signage |

| High-traffic walkways | Increased exposure during busy operations | High-visibility floor marking tape |

| Temporary or changing hazards | Risks shift throughout the day | Portable warning signs and removable floor markings |

| Poorly defined walking paths | Trips caused by confusion or obstruction | Clearly marked pedestrian walkways |

Slippery conditions can result from routine cleaning, leaks, tracked-in weather, or nearby processes. If those areas aren't marked clearly, it increases the likelihood of injury. According to the Bureau of Labor and Statistics (BLS), slips, trips, and falls accounted for 674,100 injuries in the 2021-2022 calendar year. Of those, 700 were fatal.

These signs are even more effective when paired with floor marking solutions like high-contrast tape or anti-slip strips, which can guide people safely around wet zones. Together, they provide a low-cost but high-impact way to prevent one of the most common workplace injuries.

Why Floor Marking Solutions Reduce Slips, Trips, or Fall Risks

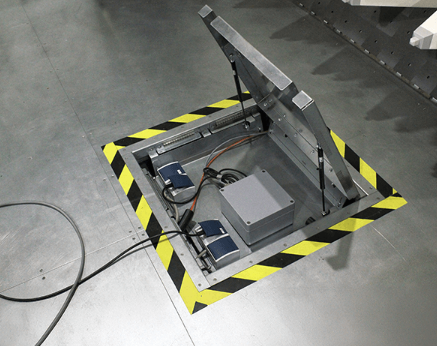

Floor markings don’t just organize your space, they help keep people on their feet. Floor marking solutions define walkways, alert workers to hazards, and show where it's safe (or unsafe) to move. And when things get busy, these visuals work as instant reminders to stay alert.

Common floor marking applications include:

-

Pedestrian walkways and forklift paths

-

“Do Not Block” zones near equipment or emergency exit signs

-

Caution tape around wet or uneven areas

-

Visual guides for stairwells and elevation changes

During OSHA inspections, damaged or faded tape often gets flagged. But well-maintained, clearly visible floor markings show that your facility takes safety seriously. Combined with proper signage, they form the backbone of a solid hazard communication system.

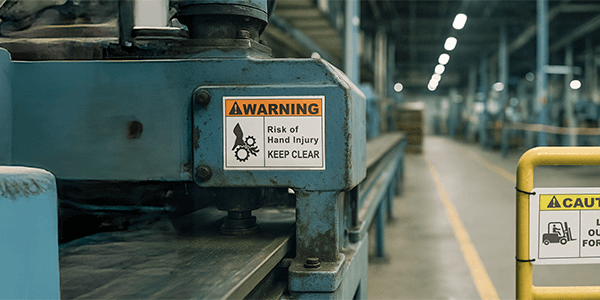

The Role of OSHA Safety Signs in Preventing Workplace Accidents

When it comes to keeping workers safe, OSHA safety signs are required. Under Occupational Health and Safety (OSHA) standard 29 CFR 1910.145, employers must post clear, visible signage that alerts employees to hazards, required actions, or emergency equipment.

This includes everything from fire extinguisher signs to arc flash warnings and evacuation routes.

But not every hazard fits neatly into a generic sign template. That’s where custom signage becomes essential. Custom workplace hazard signs allow facilities to:

- Use language and visuals specific to their layout or equipment

- Include multiple languages if needed

- Meet OSHA and ANSI Z535 formatting requirements

- Improve visibility in harsh or low-light conditions

For example, a custom fire extinguisher sign might feature directional arrows and glow-in-the-dark material for quicker access in an emergency. Similarly, emergency exit signs designed for complex layouts can help reduce confusion during a facility evacuation.

How Can Slips, Trips, and Falls Be Prevented in the Workplace?

A lot of slip, trip, and fall prevention relies on the ability of your workforce to recognize where these hazards are found and know how to use safe work practices to minimize their risk.

OSHA currently does not have a formal requirement for training on slips, trips, and falls, however, workers need to receive some type of training and reoccurring refreshers in OSHA regulations to be able to decrease the occurrence of these types of incidents in their workplace.

One of the easiest and most effective ways to keep the workforce fresh on this topic is to craft a training plan where employees can learn:

- OSHA’s regulations for walking/working surfaces

- Slips, trips, and falls and what causes them

- How to avoid slips, trips, and falls in the workplace

The amount of training can be done at the worker’s own pace or in a more formal setting. Once training is set up, visual communication can help retain the information.

How Can Visual Communication Be a Preventative Method for Workplace Safety?

Most workplace accidents are preventable, including accidents that involve slips, trips, and falls. Most of these types of incidents are caused by obstructions in walkways, while the rest are a result of uneven surfaces.

Preventing these accidents is often simple and cost-effective. Many visual communication methods can reinforce safety training in any work environment. Here are some visual communication methods that can work in any facility:

Why Floor Marking Solutions Are Essential for Hazard Prevention

Floor marking can act as a visual guide to not only workers but visitors too by defining safe pathways. Brightly colored floor markings can highlight walkways, emergency exits, and other areas where caution may be needed. Clearly marked walking paths and equipment zones ensure safe movement and prevent slips, trips, and falls. For instance, directional floor tape can guide workers safely around obstacles, reducing the risk of a safety hazard.

The Role of OSHA Safety Signs in Reducing Workplace Accidents

Signs can provide clear instructions and warnings to workers of any hazard present in their environment. For instance, “Watch Your Step” signs remind workers to be mindful of uneven surfaces.

How LabelForge PRO Supports OSHA/ANSI-Compliant Sign Design

A crucial part of effective visual communication is how signs and labels are designed. That’s where LabelForge® PRO Design Software helps—labeling software that makes OSHA/ANSI-compliant sign creation faster and easier, even for non-designers.

With LabelForge PRO, teams can:

- Choose from pre-configured OSHA/ANSI templates

- Customize text, symbols, and layouts for their facility

- Create signs in multiple languages or for unique hazards

- Export print-ready files for use with compatible printers

Whether the need is wet-floor warnings, pathway directions, chemical hazard labels, or custom safety signs, LabelForge PRO provides the flexibility and compliance support to keep visual communication consistent.

Why Safety Labels Are Vital for Workplace Hazard Awareness

Labels can be effective in the workplace by clearly identifying hazards and providing clear instructions for how to avoid them. For example, labels on chemical containers can warn workers about slippery substances, while labels on equipment can notify workers about proper usage and maintenance procedures. Labels can also be used in areas with low visibility to light, such as stairwells.Custom signage can be extremely effective in the prevention of workplace hazards, as it can be tailored to any environment or facility. By creating custom signage that addresses the unique risks of any given workplace, employers can effectively communicate safety information to workers and visitors.

Customizing signs allows for more flexibility in the design and can enhance visibility more effectively than generic signs. Graphics, colors, and language can be incorporated to meet safety needs. They can be more than just informational but created to follow OSHA and other regulatory requirements too.

DuraLabel Recommended Product to Prevent Workplace Accidents

To help prevent workplace slips, trips, and falls, one highly effective solution is the DuraLabel® Bronco® Max OSHA Kit—a complete industrial labeling system designed to help you create durable, compliant safety signs and hazard labels in-house.

DuraLabel Bronco Max OSHA Kit is an all-in-one kit that includes the Bronco Max industrial label printer and a selection of premium vinyl tapes and ribbons so you can produce OSHA/ANSI-compliant safety signs and custom hazard labels right on-site. It comes with LabelForge PRO Design Software and industrial-strength supplies built to withstand tough environments, giving you the flexibility to label wet-floor warnings, pathway signs, caution labels, and more.

Download DuraLabel’s OSHA Signs Quick Start Guide. This free guide helps create OSHA/ANSI compliant safety signs, quick access to facility needs with a site inspection checklist, as well as choose the correct sign header with a simple flow chart. Get help crafting a system that will provide the safe communication you need. Call 1-888-897-5580 and one of our experts will guide you through the process.

Learn more about floor marking with DuraLabel’s free Floor Marking Quick Start Guide. It helps employers make strategic decisions about how they want to create safe pathways for pedestrians and vehicular traffic, guides workers to the tools they need, as well as reduces confusion, and improves efficiency.

Read Next:

Tips to Choosing the Optimal Floor Marking Tape

Why OSHA Required Floor Marking Fails in Summer

Related Resources

4 Signs Your Safety Communication Needs an Update

Safety signs and labels that are up to date, clearly worded, and in tact play a key role in achieving ...

Read

5 Ways to Make Workplace Safety Signs Stand Out

How Safety Signage Improves Hazard Communication and Employee Awareness Workplace safety signs play a key ...

Read

How Custom Signs Support OSHA Rules and ANSI Signage Requirements

Why Do Facilities Need Custom Signs to Meet OSHA Rules and ANSI Signage Requirements? Custom signage plays a ...

Read.png)