Visual Communication: Key for Safety and Efficiency in Manufacturing

.webp)

What is Visual Communication?

Manufacturing facilities require a delicate balance of precision, speed, and safety. Effective communication ensures smooth operations and protects the well-being of employees. While verbal and written instructions have traditionally been the backbone of communication in these settings, visual communication is a powerful tool that significantly enhances reliability and efficiency in manufacturing facilities.

Visual communication involves the use of images, symbols, colors, and other visual elements to convey important information quickly and clearly. In a manufacturing environment, this can range from visual safety signs and labels to floor markings and digital displays. The primary advantage of visual communication is its ability to convey complex information at a glance, making it easier for employees to understand and act upon.

Visual Communication for Safety

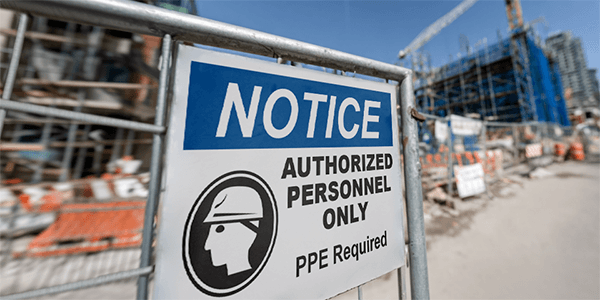

Visual communication in manufacturing facilities isn't just about quick recognition—it's about embedding safety into every aspect of the workspace. Key visual safety tools such as safety labels, signs, floor markings, and pipe markers play a vital role in both well-being and proficiency.

Instant Recognition of Hazards

- Safety Labels: Applied directly to equipment, machinery, and containers, safety labels offer critical information at the point of use, such as operating instructions or hazard warnings, ensuring that workers can quickly identify dangers and respond appropriately.

- Safety Signs: These are strategically placed to warn employees of potential hazards, indicate mandatory protocols, and provide clear instructions, reducing the likelihood of accidents. For example, a red sign with a white hand symbol clearly communicates “Do Not Touch” without the need for lengthy explanations.

- Floor Markings: These markings—like floor tape—help define safe walkways, indicate hazardous zones, and organize workflow areas. By visually separating work zones with floor tape and other signs, floor markings reduce the risk of collisions and improve overall productivity.

- Pipe Markers: Identify the contents of pipes and the direction of flow. They help prevent accidents, particularly in emergency situations where quick identification is crucial. They also aid in maintenance tasks, reducing downtime and improving operational performance.

Clear Instructions and Warnings

- Instructional Diagrams: Complex machinery and processes often require detailed instructions. Visual communication simplifies this by using diagrams and flowcharts that provide step-by-step guidance. These visuals reduce the likelihood of errors, which in turn minimizes the risk of accidents.

- Digital Displays and Dashboards: In more advanced manufacturing environments, digital displays and dashboards are used to provide real-time information about machine status, production metrics, and safety alerts. These visual cues allow workers to monitor operations continuously, respond to issues promptly, and maintain a safe working environment.

Reinforce Safety Culture

- Safety Posters and Campaigns: Beyond the immediate communication of hazards and instructions, visual communication plays a key role in reinforcing a protective culture. Posters, for instance, can remind employees of best practices or highlight the importance of specific safety protocols. When combined with regular training and meetings, these visuals help to embed a strong risk-awareness culture within the organization.

- Safety Recognition and Rewards: Incorporate visual elements that celebrate safety milestones and achievements. Displaying awards, recognition boards, or milestone markers can motivate and engage employees. By visually acknowledging those who contribute to a safe work environment, organizations reinforce the value of maintaining high protective standards and encourage ongoing commitment to visual safety practices.

Enhancing Efficiency with Visual Communication

Visual communication plays a critical role in streamlining operations within manufacturing facilities. By conveying complex information quickly and clearly through images, symbols, and color codes, it reduces the time spent interpreting instructions and minimizes the risk of errors. This rapid, clear communication not only speeds up workflow but also ensures consistency in task execution, ultimately leading to more efficient and productive operations.

Streamlining Processes

In a busy manufacturing facility, written instructions can be time-consuming to interpret, especially for new or temporary workers. Visual work instructions, such as infographics or visual aids, speed up the learning process and ensure consistency in task execution. This not only reduces the time taken to complete tasks but also minimizes errors.

Improving Workflow

The use of visual tools like Kanban boards helps manage workflow and inventory in manufacturing settings. By providing a visual representation of work progress, these systems allow teams to quickly identify bottlenecks, track inventory levels, and adjust workflows as needed. The result is a more efficient and organized production process.

Facilitating Communication Across Language Barriers

Manufacturing facilities often employ a diverse workforce, with employees from different linguistic backgrounds. Visual communication, through universal symbols and pictograms, helps bridge language barriers, ensuring that all workers understand critical safety information and operational procedures.

Implementing Effective Visual Communication in Your Facility

To maximize the benefits of visual communication in your manufacturing facility, it’s essential to follow these best practices:

Standardize Visual Elements: Use standardized symbols, colors, and formats across the facility to avoid confusion. Adopting industry standards, such as those set by the Occupational Safety and Health Administration (OSHA) or the International Organization for Standardization (ISO), ensures consistency and compliance.

Regularly Update Visuals: As processes and equipment change, so should your visual communication tools. Regularly review and update signs, labels, and instructions to reflect current conditions.

Integrate with Training Programs: Visual communication should complement, not replace, traditional training methods. Incorporate visuals into training sessions to reinforce learning and ensure all employees are familiar with the visual cues used in the facility.

DuraLabel Visual Communication Solutions

Incorporating visual communication into your manufacturing facility is a strategic move that enhances both well-being and efficiency. By providing clear, easily interpretable information, visual tools help reduce accidents, streamline processes, and foster a defensive culture. As manufacturing environments become increasingly complex, the role of visual communication will only continue to grow in importance, making it a critical component of any visual safety and optimization strategy.

Start enhancing your facility’s visual communication with the DuraLabel Toro Max Starter Kit. The kit includes the DuraLabel Toro Max Industrial Sign and Label Print System and the supplies needed to print custom industrial labels and signs. This kit has everything needed to enhance your facility’s visual communication.

If you're looking to improve protection and efficiency in your manufacturing facility, consider conducting an audit of your current visual communication tools. Get the free DuraLabel Visual Workplace Management Guide. This guide helps identify areas for improvement and takes the necessary steps to implement effective visual solutions.

Read Next:

5 FAA Safety Signage Tips for Aviation Facilities

Overcome Aviation Safety Top Challenges: Runway Safety and Incursions with the FAA

Related Resources

New Safety Controls Expand As Industrial Laser Use Grows

Laser use in industry has seen a sharp increase in the past year and the technology is being used for a ...

Read

5 Industries that Benefit from Custom Industrial Safety Signs and Why

Why Are Custom Industrial SafetySigns Essential for Protecting Workers? In every high-risk workplace, silent ...

Read

Top 10 Uses for DuraLabel Industrial Label Printers

How DuraLabel Printers are Used Across 10 Key Industrial Applications DuraLabel printers are built to solve ...

Read.png)