NEC 110 Labeling Requirements

Electrical switchgear lineup with orange NEC 110 labeling, including available fault current and equipment warning signs, supporting code-compliant arc-flash awareness and electrical safety documentation.

What Are the NEC 110.24 Available Fault Current Labeling Requirements?

NEC Article 110.24 requires electrical service equipment in non-dwelling units to be field marked with the maximum available fault current. These labels must include the calculated fault current value and the date the calculation was performed. The requirement helps facilities verify that equipment Short Circuit Current Ratings (SCCR) are adequate for the available fault current at the service. The code also requires recalculation and relabeling when modifications affect fault current levels, with limited exceptions for certain industrial installations under qualified supervision.

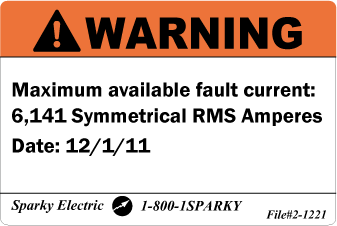

The most recent NEC Article 110 had new labeling requirements updated in 2011. The latest labels are for equipment rating purposes. These are not arc flash labels. There are three parts to the "available fault current" labels:

- Labels are required to be field installed on new equipment

- The information on the labels must be checked when changes are made

- Some facilities are exempt from these requirements

The first requirement is that labels showing the maximum available fault current be field installed.

NEC 110.24 states:

Field Marking. Service equipment in other than dwelling units shall be legibly marked in the field with the maximum available fault current. The field marking(s) shall include the date the fault current calculation was performed and be of sufficient durability to withstand the environment involved.

This requires that service entrance equipment is labeled with the available short-circuit current available when the equipment is installed. Although the equipment may have been marked by the manufacturer, that is not the label that is needed. A fault study must be done to identify the maximum amount of fault current available. In many cases, this information comes from the utility. That information and the date it was determined must be put on a label that is field applied to the equipment.

The purpose of this label is to allow the Short Circuit Current Rating of the equipment to be easily compared with the maximum available fault current. An SCCR label is usually placed on the equipment by the manufacturer. NEC's definition of SCCR is, "The prospective symmetrical fault current at a nominal voltage to which an apparatus or system is able to be connected without sustaining damage exceeding defined acceptance criteria."

Modifications. When modifications to the electrical installation occur that affect the maximum available fault current at the service, the maximum available fault current shall be verified or recalculated as necessary to ensure the service equipment ratings are sufficient for the maximum available fault current at the line terminals of the equipment. The required field marking(s) in 110.24(A) shall be adjusted to reflect the new level of maximum available fault current.

NEC 110 fault current warning label showing the maximum available fault current and date, used on electrical equipment to support code compliance and arc-flash/electrical safety signage.

This states that the maximum available fault current must be verified or recalculated any time there is a possibility it has changed. This can be difficult because, in addition to changes you make within your facility, changes made by the utility can change the maximum available fault current.

Fault current varies based on impedance, so any change in impedance will change the available fault current.Another factor that makes this confusing is that the NEC code is not universally applied. It must be adopted by the governing authority within each state. By the end of 2011, 15 states were using the 2012 version, 25 states were using the 2008 version and two states were still using the 2005 version. This means that the Authority Having Jurisdiction (AHJ) determines what labeling must be done to meet code.

The final section added to NEC 110 is the exception:

Exception: The field marking requirements of 110.24(A) and 110.24 (B) shall not be required in industrial installations where conditions of maintenance and supervision ensure only qualified persons service this equipment.

This exception is included because qualified persons know that the maximum available fault current must never exceed the SCCR of the equipment. As a part of their normal work practices, they have the necessary test equipment and will check this when changes are made to keep labels up-to-date. In addition to having the maximum available fault current and the date it was determined, the NEC code requires that the labels are able to withstand the environment in which they are located. This is a good reason to always use labels made with DuraLabel industrial label printers by DuraLabel. The DuraLabel labels have superior durability with over 50 types of supplies available. This means you can always get the right supply for the job.

Labels Warning About Deteriorating Agents

NEC is also concerned that the electrical system components are suitable for the environment in which they are used. This includes equipment such as cabinets, boxes, cable trays, raceways, conduit, elbows, fittings, couplings, supports, and support hardware. Designers and installers must select the right components based on temperature, the presence of moisture, corrosive gases, liquids, dust, sunlight or other environmental conditions that could deteriorate the equipment. Deteriorating agents include cleaning fluids, lubrication, and other workplace chemicals and substances that might come in contact with the equipment. Labeling that can survive these deteriorating agents should be used to warn about workplace substances that should not come in contact with electrical equipment. You can fulfill your labeling requirements and create custom electrical labels with DuraLabel industrial labeling kits.

Related Resources

Understanding Fault Currents and Electrical Safety

What is a Fault Current? A fault current is an unintended, high-magnitude flow of electrical current caused ...

Read

Solar Panel Safety Starts with the Right Labels

What Safety Labels Are Required for Solar Panel Installations? Solar panel safety depends on clear labels ...

Read

Available Fault Current

The National Electric Code, or NEC, requires that equipment be marked with the available fault current, and ...

Read.png)

%20(1).webp)

.webp)