NFPA 704 vs HazCom 2012

A variety of labeling standards and classification systems are available for managing chemical safety. This array of standards and changing requirements has led to confusion about what a compliant chemical label really looks like. In the United States, the most common systems are based on the NFPA 704 standard or OSHA's regulations.

To understand what's needed, you need to know the differences between three common label types:

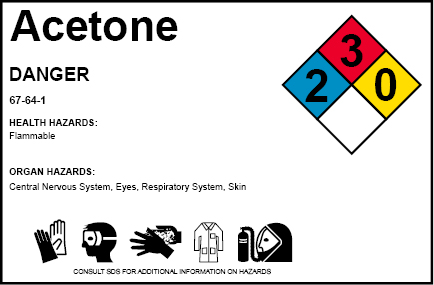

- NFPA Diamond (or Fire Diamond) labels, which follow NFPA 704

- Customized and expanded labels that are loosely based on the NFPA style

- Standardized HazCom 2012 shipping labels, which follow OSHA's updated requirements

Standards and Regulations

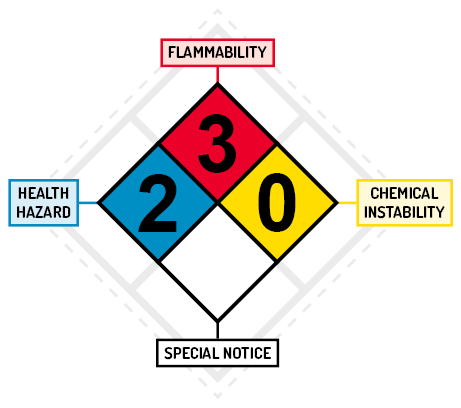

NFPA 704 was created in 1960 by the National Fire Protection Association, with the goal of helping first responders in an emergency situation. Its sign format uses bright colors and a simple design, which make NFPA 704 signs both easy to spot and easy to read. However, it only provides very limited information. Because this standard is not a law on its own, it is only mandatory where some legal authority chooses to require it.

In the United States, OSHA regulates workplace safety. Over time, the agency recognized that many safety issues were arising because workers simply didn't know about the chemical hazards they were exposed to. In 1994, OSHA created a set of rules for communicating about those hazards. These rules are often referred to as "Right-to-Know" or RTK, because they reflected the idea that each worker has a right to know about the hazards in their workplace.

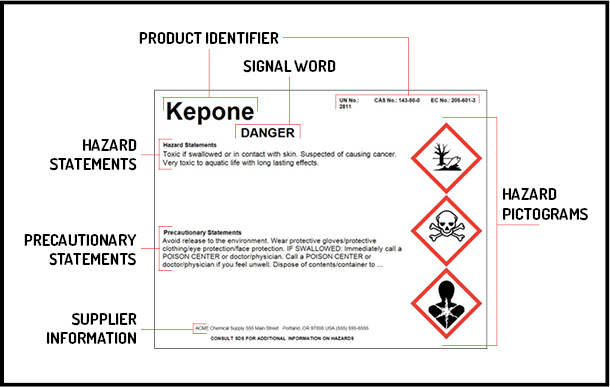

In 2012, OSHA replaced those RTK rules with a new set of requirements, incorporating elements of an international standard called the Globally Harmonized System (GHS). These updated rules for hazard communication are often referred to as HazCom 2012. The updated requirements include a label format for shipped containers, and a slightly relaxed set of rules for in-facility usage.

So what do these different labels look like?

Choosing the Right Label Format

Choosing the Right Label Format

Each label or sign format has its own purpose. To choose the right design, match the style to your need. If your goal is to ensure worker safety in normal, day-to-day operations within your facility, the NFPA 704 approach is not your best choice. Instead, consider an expanded NFPA label, or step up to the widely-standardized HazCom 2012 format. If you already have an effective protection system for your workers, but want to prepare against an emergency situation, then NFPA 704 may be the way to go. Some industries and locations may have additional requirements for these signs. For containers of hazardous materials that leave your facility, the fully-detailed HazCom 2012 format is required.

If you have questions about these labeling formats, request a free guide to the HazCom 2012 system or watch a recorded HazCom webinar on the topic to learn how OSHA's chemical safety regulations affect your facility. When it's time to print your labels and signs, consider the DuraLabel line of printers from Duralabel.

If you have questions about these labeling formats, request a free guide to the HazCom 2012 system or watch a recorded HazCom webinar on the topic to learn how OSHA's chemical safety regulations affect your facility. When it's time to print your labels and signs, consider the DuraLabel line of printers from Duralabel.

Related Resources

Avoid Costly Mistakes When Shipping Hazardous Materials

Companies fail to meet basic hazardous materials shipping requirements every year. Recently, a Columbus ...

Read

Risk Management with ISO 31000

Running a business involves risk. Risk cannot be avoided, but it can be managed. ISO 31000 provides ...

Read

Hazardous Waste Disposal

According to the Environmental Protection Agency (EPA), subtitle C of the Resource Conservation Recovery Act ...

Read.png)