Breathe Easier with Respiratory Protection Labeling for Safer Jobsites

How Can Jobsite Labeling Improve Compliance with Respiratory Protection Standards?

Jobsite labeling improves respiratory protection compliance by making PPE requirements visible at the point of use, reducing guesswork in high-risk areas. Clear labels and signs can flag construction safety hazards, identify required respirators, and reinforce fit-check and filter rules. When crews see expectations consistently, PPE construction compliance becomes easier to follow and enforce.

Respiratory protection labeling provides a simple, reliable way to reinforce safety measures. Custom industrial labels and signage make hazards, respirator requirements, and storage information clear, helping workers follow established respiratory protection guidelines and supporting Occupational Safety and Health Administration (OSHA) compliance without relying solely on verbal instruction.

The sections below explain where labeling supports respiratory protection programs, what to mark in high-exposure zones, and how to reduce noncompliance on active sites:

-

Where respiratory protection signs should be posted on jobsites

-

How labels reinforce PPE selection and exposure controls

-

Common construction safety hazards that require respiratory PPE

-

Practical labeling tips for training and daily compliance

Placement is the make-or-break piece here. We’ll walk through where to post labels and signs so they’re visible in the areas that matter most.

Respiratory Protection Risks from Construction Safety Hazards

Some of the most serious construction safety hazards cannot be seen. Dust and fumes travel easily, and exposure can have lasting health effects. That is why respiratory protection cannot be treated as optional or occasional on active jobsites.

Tasks that generate respiratory risks include:

- Concrete cutting and grinding: Generates respirable crystalline silica, a leading cause of silicosis and lung cancer.

- Welding and soldering: Releases toxic metal fumes, including hexavalent chromium.

- Insulation installation and drywall sanding: Produces fine dust that contributes to chronic bronchitis and asthma.

- Painting or coating in confined spaces: Creates exposure to chemical vapors and volatile organic compounds (VOCs).

According to the Centers for Disease Control and Prevention (CDC) and the National Institute for Occupational Safety and Health (NIOSH), nearly 20% of construction workers have a diagnosed respiratory condition. Alarmingly, one in four workers with chronic obstructive pulmonary disease (COPD) has never smoked, pointing to occupational exposure as the primary culprit.

These conditions develop gradually, often after years of exposure. That delayed onset is what makes consistent visual reminders so important, and why labeling plays a central role in reinforcing safe practices before problems arise.

Why OSHA Respiratory Protection Compliance Often Falls Short

Even with well-established rules, jobsite compliance does not always translate from paper to practice. OSHA requires formal programs under 29 Code of Federal Regulations (CFR) 1910.134 for OSHA respiratory protection and 29 CFR 1926.1153 for silica. Yet many construction sites struggle with real-world implementation.

Breakdowns often happen because:

- Generic or missing signage fails to reflect current hazards.

- Respirators and filter cartridges are mismanaged or unlabeled.

- Temporary or subcontracted crews miss safety briefings or rely on guesswork.

- Restricted areas are not clearly marked or updated as conditions change.

These gaps are not always the result of negligence. Construction environments change daily, and communication often struggles to keep up. Without visual cues to reinforce written programs and respiratory protection guidelines, even diligent crews can miss steps that protect their long-term health.

Why Respiratory Protection Compliance Breaks Down on Jobsites

Custom PPE labeling and jobsite signage help transform written plans into actionable guidance. Durable labels and signs ensure information is visible where it is needed most:

- Define hazard zones: Use durable “Respirator Required” or “Silica Exposure” signs.

- Mark and organize PPE storage: Clearly identify respirators and filter cartridges.

- Use QR codes or NFC tags: Link workers to fit-test records, SOPs, or SDS sheets on the spot.

- Bridge language barriers: Use multi-language labels and pictograms.

- Highlight engineering controls: Highlight HEPA filtration units, negative air machines, and wet-cutting areas.

These gaps are not always negligence. Construction environments change daily, and communication can lag behind. Without consistent visual cues to reinforce written programs and PPE expectations, PPE construction compliance slips, even on crews that take safety seriously.

How Respiratory Protection Labeling Supports Audits and Inspections

Effective labeling does more than guide workers, it helps demonstrate compliance when auditors or inspectors arrive. Well-labeled sites communicate that OSHA respiratory safety measures are active and enforceable.

When labels are consistent and durable, auditors can confirm at a glance that:

- Respirators and cartridges are stored properly and tracked for replacement.

- Restricted areas are posted and understood by all personnel.

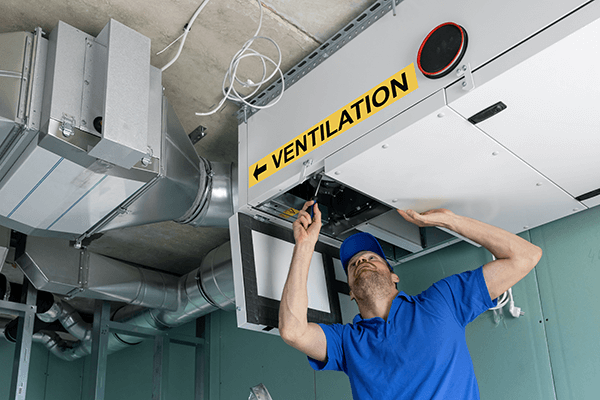

- HEPA units and ventilation equipment are clearly labeled and operational.

Sites with clear, consistent signage are more likely to avoid unnecessary citations because their compliance is immediately evident. By contrast, a jobsite with peeling or missing signage signals risk, even if its written plans are solid.

Best Practices for a Label‑Supported Respiratory Protection Program

A strong respiratory program does more than meet the minimum standard. It builds a visible, repeatable system that keeps safety top of mind. Labeling is central to that effort.

Here are best practices to put labeling to work:

- Assess hazards in real time: Update labels and signage as new tasks or materials introduce new risks.

- Mark PPE zones and storage areas clearly: High‑visibility, durable signs reduce reliance on verbal reminders.

- Label respirators and filter cartridges: Include type, usage notes, and replacement dates to prevent confusion.

- Apply GHS and hazard communication labels: Ensure all chemical storage and mixing areas have compliant visual identifiers.

- Leverage QR codes on signage: Provide instant access to fit‑test logs, cartridge change schedules, and SOPs.

- Review and refresh all labels routinely: A label that fades, peels, or disappears is a safety gap waiting to happen.

By combining administrative controls with strong visual communication, crews are better equipped to follow the respiratory protection program every single shift.

DuraLabel Custom Signage Resources

Respiratory protection is only as strong as the communication that supports it. Standard signage often falls short in dynamic construction environments where hazards shift daily. Custom labeling ensures every worker, whether permanent, temporary, or multilingual, has clear, consistent guidance to stay safe and compliant.

DuraLabel provides industrial‑grade labeling and signage solutions engineered to perform in construction’s toughest conditions. From GHS‑compliant hazard labels to on-demand custom respirator zone signage, our solutions reinforce OSHA respiratory protection practices directly on the jobsite.

Ready to strengthen your respiratory safety program? Download DuraLabel’s free OSHA Signage Quick Start Guide for step‑by‑step guidance on selecting the right headers, applying ANSI and GHS formatting standards, and choosing durable materials that withstand dust, moisture, and abrasion.

Have questions? Call 1‑888‑789‑7964 to connect with a DuraLabel safety specialist and start building a safer, more compliant jobsite with clear, lasting labels.

Read Next:

Tips to Improve Silica Compliance

Related Resources

How to Get the Most Out of OSHA Construction Signs on Site

How Can Construction Sites Reduce Risks? One of the most effective tools to reduce risk is through the ...

Read

How Contractors Use Custom Safety Labels for Job Site Safety

What Types of Labels Are Best for Construction Sites? The best labels for construction sites are durable, ...

Read

The Key to Reliable Construction Projects: Safety Signage That Works

Construction signs and labels play a crucial role in protecting workers and keeping projects on schedule. ...

Read.png)