How to Improve Eyewash Station Safety in Healthcare Workspaces

How Do Labels Comply With ANSI and OSHA Requirements in Labs?

Eyewash station labels support compliance by making emergency equipment easy to locate and use during an exposure event. Occupation Health and Safety Administration (OSHA) 29 CFR 1910.151(c) requires eyewash availability where corrosives are present, while American National Standards Institute (ANSI) Z358.1 emphasizes clear access and prompt use. Visible eye wash signage and consistent eyewash station markings help reinforce both expectations in labs and SPDs.

Our eyes are vulnerable in high-risk environments, where splash hazards and chemical exposure are part of the job. According to the Centers for Disease Control and Prevention (CDC), more than 2,000 U.S. workers sustain eye injuries on the job every day, many of them preventable with better labeling, signage, and safety protocols.

In clinical laboratories and sterile processing departments (SPDs), the use of concentrated chemicals, pressurized systems, and cleaning agents poses a constant threat to vision. While personal protective equipment (PPE) is essential, it’s not enough.

The American Academy of Ophthalmology reports that nearly 90% of workplace eye injuries are preventable when protective measures and clear visual communication are in place. Consistent labeling, visible emergency station markings, and well-placed eye wash signage help staff locate an eyewash station fast and support compliance with ANSI Z358.1 expectations.

The sections below explain eyewash station labeling best practices for labs and SPDs, how ANSI Z358.1 influences access and visibility, and what common placement issues can slow response time:

-

Where eye wash signage should be visible from in labs and SPDs

-

How ANSI Z358.1 access rules influence label placement

-

What to include on eyewash station labels for clarity

-

Common visibility and obstruction issues to correct

Why Eye Protection Requires More Than PPE

Goggles and face shields are often the first line of defense, but in fast-paced healthcare environments, even well-trained teams can become desensitized to routine hazards. Labs and SPDs regularly handle reactive substances and high-pressure tools that increase the risk of splashes and airborne exposure.

OSHA 29 CFR 1910.151(c) requires employers to provide eyewash stations where workers may be exposed to injurious corrosive materials, but equipment alone isn’t enough. If eyewash stations are difficult to find, improperly labeled. Or blocked from view, staff may be delayed in responding during an emergency.

How Can You Improve Eyewash Stations Visibility and Access?

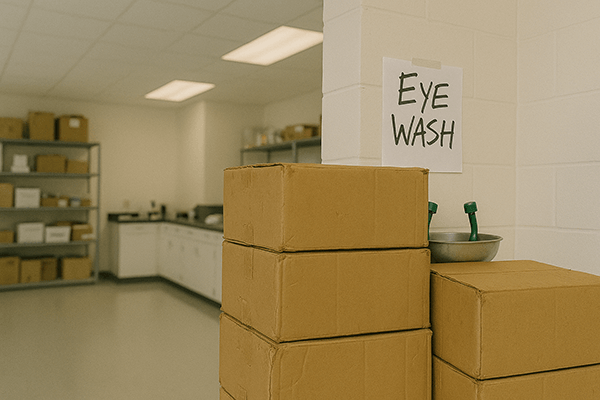

An eyewash station is a critical part of chemical safety, but it only helps if staff can locate and operate it immediately in an emergency. In labs and SPDs, stations are often blocked by carts, hidden behind doors, or effectively invisible because eye wash signage is worn, missing, or inconsistent.

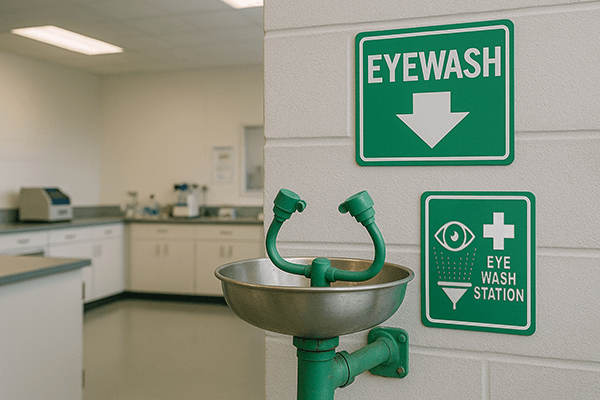

To improve response times and ensure compliance with American National Standards Institute (ANSI) Z358.1-2014, facilities should prioritize consistent labeling and clear, standardized signage. Recommended practices for eyewash station placement and labeling:

- Install signage at eye level and near all hazard zone entry points

- Apply custom labels directly to eyewash units with instructions and GHS-compliant pictograms

- Use chemical- and moisture-resistant materials suitable for lab and SPD conditions

- Add directional indicators if units are located around corners or behind barriers

In facilities that handle chemicals such as formaldehyde or xylene, delays in finding an eyewash station can result in long-term damage. Clear, standardized labeling helps eliminate uncertainty and supports faster emergency response.

Eye Wash Signage That Promotes Everyday Eye Safety

While eyewash stations are the emergency response, eye safety signage serves as everyday prevention. SPDs face a higher risk of eye injuries due to regular exposure to cleaning agents, disinfectants, and sterilization equipment. In these settings, visual reminders help staff alert to ongoing risks, even during routine tasks. Effective signage should communicate expectations clearly, visually, and in context. Key considerations for awareness signage include:

- Use direct, action-based language such as “Wear Eye Protection When Operating”

- Include ANSI-compliant icons for universal recognition

- Offer multilingual options that reflect workforce needs

- Update signage regularly to avoid desensitization and ensure readability

Signage placement should be strategic, located where hazards are likely to occur. The goal is to ensure workers are reminded of the risk at the exact moment it matters.

Simplify Eyewash Station Labeling with LabelForge PRO

Maintaining consistency across labeling systems can be difficult, especially in large healthcare networks or departments with rotating staff. LabelForge PRO Design Software offers a way to simplify that process by providing easy-to-use templates that support OSHA and ANSI Z358.1 compliance while adapting to department-specific needs.

The free LabelForge PRO includes pre-built formats for eyewash stations, PPE areas, and emergency equipment. Labels can be customized, translated, and printed using durable materials that hold up in harsh conditions common to labs and SPDs. By centralizing the labeling process, facilities can reduce errors, improve consistency, and maintain visual standards across locations.

Strengthening Eyewash Station Safety Through Visual Communication

A successful eye safety program doesn’t rely on equipment alone. It depends on a consistent system of visual cues that guide behavior, reduce ambiguity, and support rapid decision-making.

Steps for strengthening visual communication in labs and SPDs:

- Conduct visual audits of eyewash stations and related signage at least quarterly

- Apply custom labels near hazardous equipment to reinforce operating procedures

- Integrate signage and labeling into onboarding and ongoing staff safety training

- Include signage checks as part of regular safety rounds or compliance reviews

Visual consistency promotes faster reaction times, clearer understanding, and better adherence to established protocols, which protects both workers and patients in the process.

DuraLabel Eye Safety Awareness Signage Resources

Effective eyewash station signage, custom labeling, and eye safety awareness signage are essential for reducing eye injuries. Standardizing visual communication across departments helps improve response times but ensure alignment with OSHA and ANSI standards.

For facilities looking to improve labeling consistency across high-risk areas, LabelForge® PRO offers a streamlined way to create compliant, durable labels tailored to healthcare environments. Its pre-built templates and customizable options help standardize critical information across departments, reducing the risk of mislabeling chemicals, emergency equipment, and PPE zones.

To learn more about how to support broader chemical safety and injury prevention, download DuraLabel’s free HazCom Quick Reference Guide. It provides a clear overview of OSHA’s Hazard Communication Standard, GHS label elements, and best practices for identifying hazardous substances. It also provides ways to improve label visibility, and selecting the right materials that perform in demanding settings.

If you have questions or need assistance implementing a labeling system that supports your safety goals, our experts are here to help. Contact us at 1-877-534-5157 to speak with a specialist and they will guide you through the process.

Read Next

What’s the Real Cost of Failing to Meet OSHA Safety Standards?

HazCom Basics: Chemical Labeling 101

Related Resources

Hazardous Chemical Storage Risks and GHS Labeling Solutions

How Do Labels Support Safe Chemical Storage? Labels support safe storage of hazardous materials by clearly ...

Read

Workplace Chemical Labels and GHS Requirements Explained

What is Chemical Labeling? Clear chemical labels help workers recognize hazards quickly, select the right ...

Read

Hazard Control Hierarchy and Lab Safety Labels for Chemical Hazards

What Are Lab Safety Labels? Lab safety labels are visual identifiers that communicate chemical and process ...

Read.png)