Electrical Safety Gap Analysis: OSHA and NFPA 70E Safety Standards

Why Is an Electrical Safety Audit Critical for Workplace Compliance?

No electrical system is without gaps. Often, third parties are best equipped to evaluate existing HSE management systems.

We've come a long way from Thomas Edison's light bulb. Today, electricity powers our workforce, connecting mechanical assembly lines and propelling conveyors across the country.

Electricity is an integral component of our way of life and global economy, but it's not without hazards. Electrical hazards can be unpredictable and dangerous, placing engineers, electricians, and other professionals in harm's way. A thorough electrical safety audit provides the oversight and accountability needed to align with both OSHA and NFPA 70E standards for electrical safety.

Effective Health, Safety and Environmental (HSE) management systems deploy a variety of training procedures and safeguards to lower their company's Total Recordable Incident Rate (TRIR) and ensure workers and assets are protected. Forward-thinking companies contract a third party to provide an electrical safety gap analysis.

Understanding the Electrical Safety Gap Analysis Process

The premise is simple: No electrical system is without gaps. Often, third parties are best equipped to evaluate existing HSE management systems to pinpoint strengths and opportunities for improvement. Depending on the size of your company, these on-site evaluations can be completed in an afternoon or over the course of a few days.

An electrical safety gap analysis:

- Examines low-cost solutions to meet regulatory compliance needs

- Documents safety measures for OSHA audits and compliance

- Creates safety proposals for budget generation

- Provides recommendations and regulatory standards for personal protective equipment (PPE)

- Offers an in-depth report of recognized gaps or "hazards"

When in doubt, call in the cavalry. A trained professional will not only evaluate your electrical safety program, but help prevent accidents and fines.

Electrical Regulatory Standards

Electrical hazards inundate OSHA's Top Ten Safety Violations year after year, affecting a multitude of industries. An electrical safety gap analysis can help prevent your company from becoming a fateful statistic.

OSHA'S Top 10 Safety Violations for 2014 included:

- Powered industrial trucks, with 3,147 violations (No. 5)

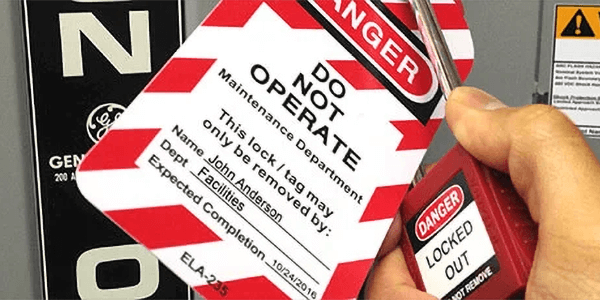

- Lockout/Tagout (LO/TO), with 3,117 violations (No. 6)

- Electrical/wiring methods, with 2,907 violations (No. 8)

- Machine guarding, with 2,520 violations (No. 9)

- Electrical/general requirements, with 2,427 violations (No. 10)

OSHA's electrical standards are designed to protect employees exposed to dangers such as electric shock, electrocution, fires, and explosions. While electrical hazards are addressed in specific standards for the general industry (29 CFR 1910), shipyard employment (29 CFR 1915), and marine terminals (29 CFR 1910), the benchmark for safety in workplace practice is established by the National Fire Protection Association (NFPA) and the standard NFPA 70E.

NFPA 70E defines work practices that protect workers from electrical hazards during the inspection, operation, and maintenance of electrical equipment. NFPA 70E also specifies safe work practices for employees who may not be directly working on electrical equipment, but who are performing work that might expose them to electrical hazards.

An electrical safety gap analysis will walk your HSE professionals through complex regulatory standards, and most importantly, provide real-world safety applications and resources. Much like Edison's first light bulb, successful safety programs must evolve, constantly be tinkered with, and be open to scrutiny.

Related Resources

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA’s Standard for Electrical Safety in the Workplace, outlines specific ...

Read

Electrical Hazard Prevention Starts with Awareness

Why Is Electrical Safety Awareness Important in Every Workplace? Electrical safety awareness is essential for ...

Read

How to Prevent Arc Flash with Lockout/Tagout Signs and Safety Labels

What Are the First Steps to Preventing an Arc Flash Accident in the Workplace? In the realm of electrical ...

Read.png)