Six Sigma Methodology

As the name implies, a Lean Six Sigma methodology combines the principles of lean manufacturing ("Lean") with those of Six Sigma. But why would anyone want to do this? What are the advantages and disadvantages of combining Lean and Six Sigma methodologies?

What Does Lean Contribute?

Lean is a process of continual improvement based and increasing value for the customer. The objective is to eliminate anything that does not contribute to what a customer is willing to pay for. This puts the focus on eliminating waste and streamlining the process of delivering the product or service.

Lean involves applying a number of principles and methods, including 5S organization principles, which include:

- Kaizen - the principle of continuous improvement based on employee suggestions.

- Kanban - customer demand "pulls" the product through the production process.

- TPM - Total Productive Maintenance is used to reduce equipment downtime.

- TQM - Total Quality Management continually improves product and service quality.

- 5S System - improving quality and efficiency through cleaning up and getting organized.

- SMED - the principles of Single Minute Exchange of Die reduce the time needed to change a machine or production line to produce a different product.

Lean is a tool used by businesses to streamline manufacturing and production processes. The main emphasis of Lean is on cutting out unnecessary and wasteful step so that only the steps that directly add value to the product remain.

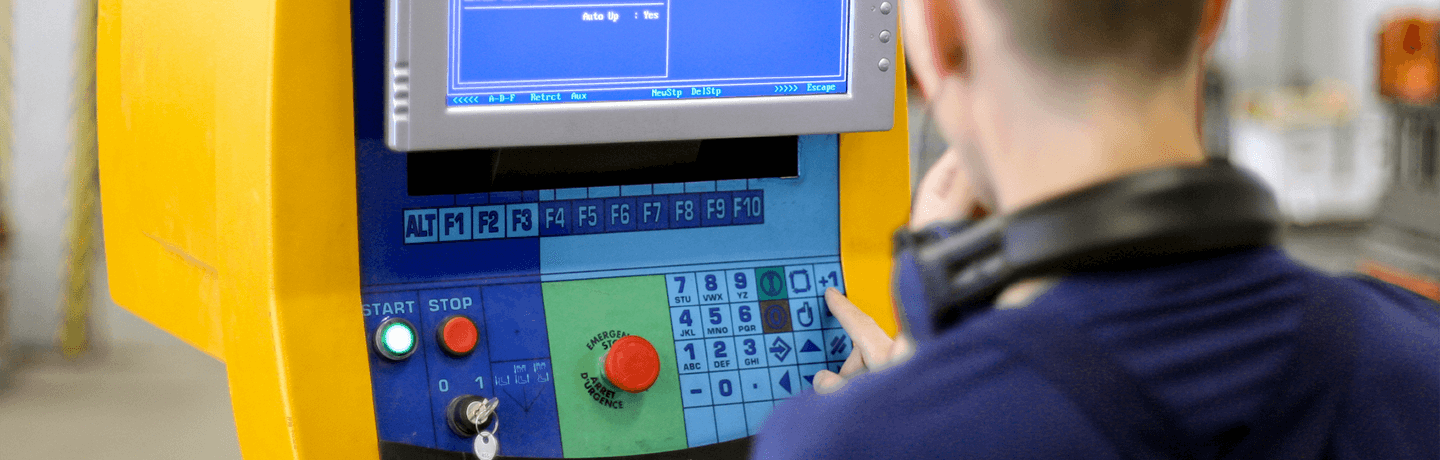

Lean Six Sigma Methodology Visual Communication

Without clear, effective visual communication, implementing Lean Six Sigma methods will be next to impossible. Visual communication using signs and labels delivers needed information at the physical locations and times when it is most needed. Learn more about DuraLabel label and sign solutions from Duralabel.

Related Resources

DFSS (Design For Six Sigma): A Customer Centered Process

What Is Design for Six Sigma and How Does It Improve Product Design? Design for Six Sigma (DFSS) is a ...

Read

Kaikaku: Driving Radical Change in Lean Systems

What Is Kaikaku and How Does It Support Lean Transformation? Kaikaku is the Japanese word for "radical ...

Read

Six Sigma Principles: Exploring Six Sigma, Lean, and The 5S System

What is Six Sigma? Six Sigma is a systematic approach to eliminating errors that harmonizes with 5S and 5S ...

Read.png)