Inside the Changes to NFPA 70 Electrical Labeling

What Changed in NFPA 70 Electrical Labeling in 2026?

In the current edition of the National Fire Protection Association’s NFPA 70, the National Electrical Code (NEC), most electrical labeling requirements remain consistent, but one key area was clarified and updated. The primary change affects arc flash hazard labeling under Article 110.16, which now requires specific, data-driven information rather than general warning language.

These updates clarify how NFPA 70 electrical labeling requirements are applied, particularly for arc flash hazards. Requirements for equipment identification, disconnecting means, photovoltaic systems, and battery installations largely carry forward, allowing contractors and safety teams to focus their updates where labeling expectations were clarified.

NFPA 70 labeling updates center on five areas:

- How NFPA 70 approached labeling prior to the latest update

- NFPA 70 labeling requirements that remain unchanged

- The labeling requirement that changed in NFPA 70

- Why the arc flash assessment date matters

- Implications for labeling programs and asset design

How NFPA 70 Approached Labeling Prior to the Latest Update

Labeling requirements have long been part of NFPA 70, outlined across multiple articles covering equipment identification, disconnects, conductor marking, photovoltaic systems, battery installations, and energy storage.

In prior editions, Articles 110.3 and 110.21(B) emphasized clarity, durability, and environmental suitability. Labels were expected to identify what the equipment was, what it served, and where hazards might be present. However, earlier editions left the specific content of many labels largely to the installer, equipment owner, or Authority Having Jurisdiction (AHJ).

The code focused more on outcomes than on prescriptive wording. If a label clearly identified an arc flash hazard and could withstand its environment, it was generally considered compliant. This was especially true for arc flash labels, where generic warning language was commonly accepted. As long as labels indicated danger and met durability expectations, they typically satisfied the code requirements.

The current edition of NFPA 70 narrows how labeling rules are interpreted and establishes clearer expectations, particularly in areas tied directly to worker safety.

NFPA 70 Labeling Requirements That Remain Unchanged

One of the most important takeaways is that most labeling requirements in NFPA 70 remain consistent. These provisions continue to apply without substantive revision, meaning many existing NFPA 70 labeling practices remain valid when originally installed in compliance with the standard.

General Marking and Durability Requirements

NFPA 70 Articles 110.3 and 110.21(B) establish the foundational requirements for electrical labeling. Equipment must be listed and labeled as appropriate, and markings must be durable enough for the environment in which they are installed. These expectations remain unchanged.

From a labeling perspective, the requirement is straightforward. Labels must be legible, permanent, and suitable for the conditions where they are installed.

Disconnect Identification

NFPA 70 Article 110.22 governs the identification of disconnecting means. Disconnect labels must clearly identify the equipment served. In non-dwelling occupancies, labels must also include the source identification and location when that information isn’t otherwise evident.

This reinforces current disconnect labeling requirements under NFPA 70 and the need for clear, equipment-specific labeling rather than shorthand or generic identifiers.

Multiple Nominal Voltage Systems

NFPA 70 Article 210.5(C) addresses conductor identification and panel legends for systems supplied by more than one nominal voltage. Conductors must be identified by system, and a permanent legend explaining the identification method must be posted at each panelboard.

This requirement remains unchanged and continues to drive the need for dedicated electrical panel legend labels.

Solar Photovoltaic Labeling

Photovoltaic labeling requirements under Article 690.31 continue to focus on hazard identification, warning placement, and visibility. A minor wording adjustment to rapid shutdown labels in Article 690.12(D) is editorial in nature and does not change safety intent.

Similarly, existing electrical labeling requirements remain in place for:

- Electric signs

- Fixed electric space-heating equipment

- Stationary batteries

- Energy storage systems

For these systems, current practices remain valid when originally compliant with NFPA 70.

The Labeling Requirement That Changed in NFPA 70

The most significant and consequential labeling change affects arc flash hazard labeling.

Arc Flash Hazard Labeling Requirements Under NFPA 70 Article 110.16

NFPA 70 Article 110.16 was substantially revised, directly affecting how arc flash labels are designed, applied, and evaluated. Unlike other labeling provisions that carried forward with minimal adjustment, this revision clarifies both the purpose and required content of arc flash hazard labels.

The revised language narrows how arc flash labeling requirements are interpreted. Arc flash labels are no longer treated as general warnings but as informational safety tools intended to communicate specific risk data before energized work is performed.

What NFPA 70 Now Requires on Arc Flash Labels

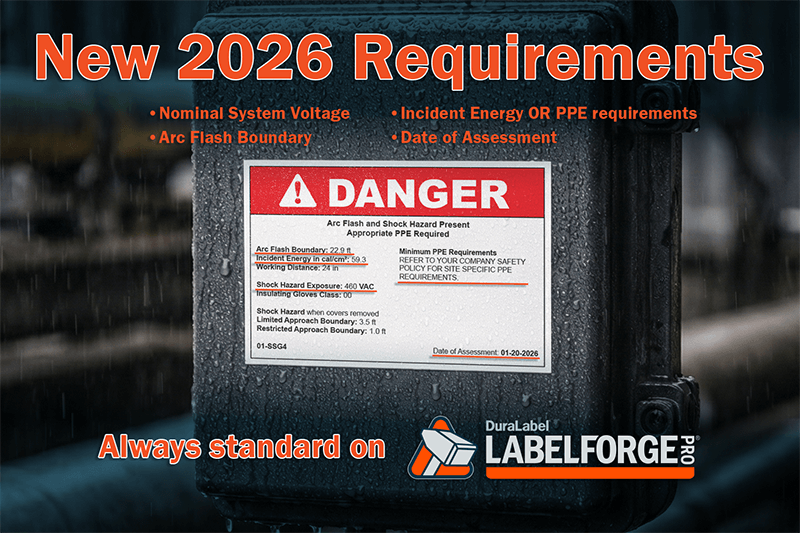

NFPA 70 Article 110.16 now requires arc flash hazard labels to include specific, actionable information that supports informed decision-making before energized work.

Arc flash labels must include the following elements:

- Nominal system voltage

- Arc flash boundary

- Available incident energy or the minimum required arc-rated personal protective equipment (PPE) level

- Date the arc flash risk assessment was performed

Generic warning-only labels are no longer sufficient. The revision consolidates prior subsections into a singular marking requirement, reducing variation in arc flash label content.

Here’s how arc flash labeling expectations have shifted between 2023 and 2026 editions of NFPA 70:

|

Labeling Element |

2023 Edition (Article 110.16) |

2026 Edition (Article 110.16) |

|

Where Labels Apply |

Service equipment and large feeders (typically 1000 amps or more). |

All non-dwelling equipment likely to require examination, adjustment, servicing, or maintenance while energized, with no amp threshold. |

|

Label Purpose |

General arc flash warning. |

Clear, usable safety info for workers at the point of risk. |

|

Required Label Content |

Unspecified. Label text and format left to user interpretation. |

Four required elements: system voltage, arc flash boundary, incident energy or PPE level, and assessment date. |

|

Risk Assessment Date |

Not required. |

Required. The arc flash risk assessment date must be printed directly on the label. |

|

Durability Standard |

Labels had to be legible and hold up in the field. |

No change. Material durability expectations remain the same. |

|

Interpretation Flexibility |

Labels were often accepted with minimal information, provided durability and visibility requirements were met. |

Narrower. Labels must meet content requirements to be compliant. |

|

Compliance Implication |

Generic warning-only labels were commonly accepted. |

Generic warning-only labels no longer meet Article 110.16 content requirements. |

This breakdown shows how the 2026 edition shifts arc flash labeling from general warnings to structured, data-driven safety information, and why facilities should review their existing labels for compliance.

Why The Arc Flash Assessment Date Matters

Including the date of the arc flash risk assessment ties the label directly to the accuracy of the underlying analysis.

Electrical systems change over time. Equipment is modified, system configurations shift, and available fault current can change. When that happens, an outdated assessment date becomes a visible signal that the information on the arc flash label may no longer reflect current conditions.

From a labeling standpoint, this reinforces that arc flash labels are living safety documents tied to the condition of the electrical system. Including the assessment date helps qualified workers quickly determine whether arc flash information is current before performing energized work.

Implications for Labeling Programs and Asset Design

For most labeling categories, continuity remains the guiding principle under NFPA 70. Existing label designs that meet NFPA 70 requirements do not require redesign. Arc flash labeling is the exception.

Organizations should plan to review and update arc flash label templates to ensure they can:

- Accommodate multiple variable data fields

- Clearly present electrical values and hazard boundaries at the point of use

- Include a visible arc flash risk assessment date

- Meet durability requirements outlined in NFPA 70 Article 110.21(B)

This shift also changes how arc flash labels should be viewed internally. They function as part of a broader risk communication system intended to support informed decision-making by qualified personnel throughout the life of the electrical system and its assets.

NFPA 70 Labeling Resources and Support

Recent updates to NFPA 70 reinforce a clear takeaway for safety programs and compliance teams: most requirements remain consistent, while expectations for arc flash hazard communication have become more precise.

For teams looking for a practical starting point, the free DuraLabel® Electrical Safety Quick Start Guide outlines core electrical safety concepts, including arc flash awareness, hazard communication, and electrical labeling considerations aligned with NFPA standards. The guide is designed to help organizations evaluate current practices and identify where updates may be needed.

DuraLabel supports NFPA 70–aligned labeling through resources focused on label design, material selection, and long-term durability in electrical and industrial environments. Industrial-grade printers, supplies, and LabelForge® Pro Design Software work together to help facilities create and maintain NFPA-aligned electrical equipment labels, including arc flash and equipment identification labels, even in demanding environments where heat, moisture, abrasion, and chemical exposure are common.

Have questions about NFPA 70 labeling requirements or arc flash label design? DuraLabel’s safety and labeling specialists can help evaluate your application and compliance needs. Call 1-888-789-7964 to connect with a DuraLabel safety specialist.

Read Next:

Why Engineers Rely on LabelForge PRO for OSHA Electrical Safety

The Importance of Electrical Labeling for Electrical Installations

Related Resources

Solar Panel Safety Starts with the Right Labels

What Safety Labels Are Required for Solar Panel Installations? Solar panel safety depends on clear labels ...

Read

NEC 110 Labeling Requirements

What Are the NEC 110.24 Available Fault Current Labeling Requirements? NEC Article 110.24 requires electrical ...

Read

What Every Engineer Should Know About Preventing Arc Flash Incidents

How Can Labeling Help Prevent and Arc Flash Incident? An arc flash incident occurs when electrical current ...

Read.png)

.webp)