How Custom Signs Support OSHA Rules and ANSI Signage Requirements

Why Do Facilities Need Custom Signs to Meet OSHA Rules and ANSI Signage Requirements?

Custom signage plays a critical role in workplace safety compliance across U.S. industries. During inspections by the Occupational Safety and Health Administration (OSHA), one of the first things inspectors check is the condition and clarity of signage. For facilities with unique layouts, equipment, or hazards, off-the-shelf signs often fall short. That’s where custom signs become essential for meeting OSHA rules and ANSI signage requirements.

Understanding OSHA and what is ANSI standards is only part of the equation. This article explores how custom signs help translate those standards—and broader ANSI compliance expectations—into practical, site-specific safety tools.Federal Safety Requirements Shape the Role of Visual Communication

Visual communication is legally mandated in most industrial settings. OSHA outlines enforceable rules in 29 CFR 1910.145 for accident prevention signs. These requirements specify how hazards must be communicated using standardized signal words, colors, and visibility criteria.

To be OSHA-compliant, a sign must:

- Use signal words such as “Danger,” “Warning,” or “Caution”

- Follow OSHA’s color coding: red for immediate danger or yellow for caution

- Remain legible from a safe viewing distance under normal lighting conditions

Failure to meet these requirements can result in citations. According to 2023 data from the Bureau of Labor Statistics (BLS), unclear or missing signage contributed to hundreds of incidents involving hazardous energy, chemical exposure, and moving machinery.

The American National Standards Institute (ANSI), though not a regulatory body, provides additional guidance through its Z535 standards. Much of what is ANSI centers on defining best practices for formatting, layout, and design. ANSI-compliant signs typically feature standardized icons, structured layouts, and carefully selected fonts and spacing to improve readability. These Z535 expectations shape modern ANSI signage requirements across industrial facilities.

The ANSI Z535 series is widely adopted across industries and often cited during OSHA enforcement, especially when evaluating whether an employer has taken reasonable steps to communicate a hazard and maintain ANSI compliance.

Custom Signage Provides Targeted Solutions for OSHA and ANSI Compliance

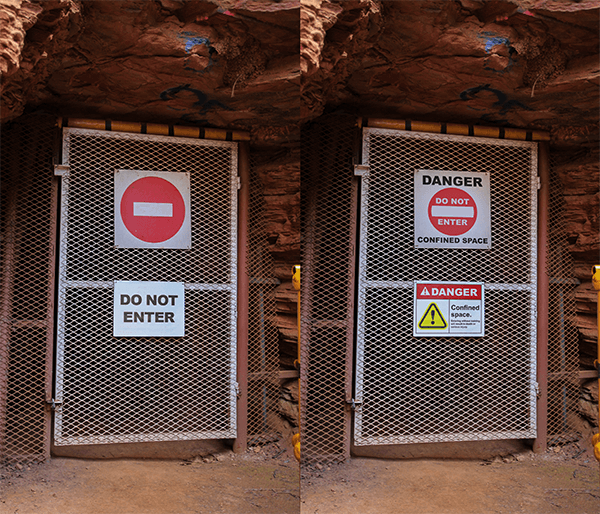

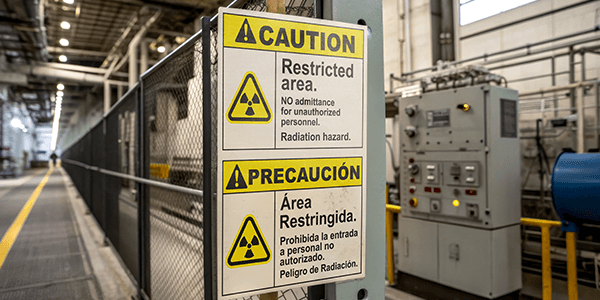

Custom signs are designed to meet site-specific safety needs while remaining fully aligned with OSHA rules and ANSI signage requirements. A trusted ANSI-compliant danger workplace signage setup can include hazard-specific messaging, relevant instructions, and multilingual content tailored to a facility’s workforce.

In facilities where a single piece of equipment may pose multiple hazards, custom signs are more effective than generic alternatives. For example, a boiler room might require warnings for high temperatures, confined space entry, and chemical exposure. A custom sign can consolidate all of these hazards into a single panel—supporting both OSHA and ANSI compliance.

In chemical-processing environments, the U.S. Chemical Safety Board recommends using site-specific signage that conveys critical information quickly. During an emergency, a generic “Danger” sign may not provide the level of detail workers or emergency responders need. This is especially true in multilingual environments, where bilingual safety signs ensure clarity and strengthen adherence to ANSI signage requirements.

Custom signage also allows employers to integrate in-house safety procedures directly into visual communication. In facilities with permit-required confined spaces, for instance, a custom sign might include steps for checking a logbook or contacting a supervisor before entry. This type of specificity goes beyond standard OSHA text while reinforcing compliance with Subpart J of 29 CFR 1910.

Designing Custom Signs That Align with OSHA and ANSI Signage Requirements

Custom design does not exempt employers from compliance. A well-designed custom sign must include all visual elements required by OSHA and recommended by ANSI. These elements include:

- A signal word such as DANGER, WARNING, or CAUTION

- The safety alert symbol (a triangle with an exclamation point), when applicable

- Short, action-oriented descriptions of the hazard

- ANSI-recognized pictograms, where appropriate

Signs must also meet legibility standards. ANSI Z535.2 outlines minimum character heights based on viewing distance. Text must be large enough and printed in fonts that are readable from a safe distance, with high contrast between text and background to ensure visibility.

Durability is another critical compliance factor. OSHA requires that signage remain legible under expected environmental conditions. In areas exposed to chemicals, water, UV radiation, or extreme temperatures, facilities should choose high-durability materials such as laminated vinyl, polycarbonate, or metal substrates. According to the National Safety Council (NSC), faded or damaged signs are among the most common deficiencies identified during facility audits.

Beyond compliance, custom signs support better safety outcomes. The right sign reinforces training, guides behavior, and improves emergency response by communicating clearly when it matters most.

Custom Signs Reduce Incidents and Improve Safety Outcomes

Site-specific signage improves hazard recognition and reduces response time during incidents. Many industries have reported positive safety benefits after implementing custom sign programs based on OSHA and ANSI signage requirements.

In the chemical industry, GHS-compliant custom labels with ingredient-specific warnings have helped emergency responders identify spill risks more efficiently. Facilities using custom pictograms alongside written instructions experienced faster containment during drills and scored higher in hazard communication audits.

Custom signage that reflects actual equipment layouts reinforces safe procedures and strengthens training retention. The National Safety Council recommends site-specific labeling as a core element of ongoing hazard communication and control efforts, especially in workplaces where tasks vary by department, shift, or equipment type.

Selecting a Vendor That Understands OSHA Rules and ANSI Compliance

A custom sign is only as effective as the process behind it. Employers should partner with signage providers who deeply understand OSHA rules and ANSI signage requirements. Look for an ANSI-compliant danger workplace signage provider who offers:

- Access to ANSI-aligned templates

- Multilingual design support

- Material selection based on environment conditions

- Support for custom GHS and NFPA sign layouts

- Printing technologies that support legibility and durability

- Industry-specific knowledge in construction, manufacturing, healthcare, and logistics

The National Association of Safety Professionals (NASP) recommends documenting the rationale behind each custom sign. This step demonstrates due diligence during compliance audits and provides justification for any deviation from standard templates.

ANSI Compliance and OSHA Planning Start with Proper Execution

Custom signage is not just a best practice. It is often the most effective way to comply with OSHA mandates and ANSI signage requirements. Tailored visual communication allows employers to address unique hazards while maintaining consistency and professionalism across the facility.

With hazard communication violations consistently ranking among OSHA’s top ten citations annually, custom signs represent a proactive solution. When properly planned and reviewed for both OSHA rules and ANSI compliance, they not only meet the standard—they help protect lives.

OSHA and ANSI Compliance Resources from DuraLabel

OSHA-compliant signage requires more than bold letters and caution tape. It relies on standardized formatting, consistent application, and durable materials that withstand tough industrial environments. Whether you're labeling hazardous areas, marking restricted zones, or updating general facility signage, understanding OSHA’s sign requirements is essential for long-term compliance.

DuraLabel’s free OSHA Signs Quick Start Guide provides a practical overview of what compliance looks like in the field. The guide explains OSHA’s formatting rules for signal words like “Danger,” “Warning,” and “Caution,” offers visual examples of compliant signs, and outlines common sign types by application. You'll also find material recommendations based on environmental exposure, and best practices for optimizing visibility and placement. Download your copy today.

For teams needing on-demand custom signage, the DuraLabel Toro Max Industrial Sign and Label System delivers a flexible, all-in-one solution. With built-in design software and durable supply options, Toro Max makes it easy to create site-specific, compliant signs, right wherever they are needed, ideal for maintenance crews, field operations, and dynamic facilities where conditions change and signage needs to adapt.

Need help selecting the right signs, materials, or printers? Call us at 1-888-789-7964 to speak with a DuraLabel safety and compliance specialist.

Read Next:

What Is HazCom? Your Guide to Chemical Labeling, GHS, and OSHA Standards

Top 10 Uses for DuraLabel Industrial Label Printers

Related Resources

4 Signs Your Safety Communication Needs an Update

Safety signs and labels that are up to date, clearly worded, and in tact play a key role in achieving ...

Read

Custom Signage Built Around OSHA ANSI Signs for Safer Workplaces

How Do Slippery When Wet Signs Prevent Common Workplace Injuries? Slippery When Wet signs prevent common ...

Read

The Case for Custom Workplace Signs in Complex Environments

Why Do Custom Industrial Labels Outperform Standard Signs in Facility Environments? Custom workplace signs ...

Read.png)