LNG Demand Calls for Effective Safety Solutions

Next generation energy leaders will convene Sept. 17-19 at Gastech in Houston, the world's largest marketplace for the gas, LNG, and energy industry. It's the first time the show has been held in the United States in about 30 years. What makes this conference buzz this year is the focus on liquid natural gas. Extraction, transportation, compression, storage, and regasification are all activities that are part of the LNG process. While LNG is a safe option for fuel and generating power, there are still several key tips for next gen professionals to keep in mind for efficiency as the demand for LNG surges.

LNG Growth Continues

LNG supplies are fast growing worldwide, with China leading the demand, according to Shell's Energy and Innovation report. Globally, the demand is set to reach 384 million tonnes in 2020, making LNG a fuel for the future, a Shell executive said, citing new projects the company is focusing on as a cost-competitive and cleaner transport fuel, especially for shipping and heavy-duty road transport.

"Shell has signed a deal with ship cruise operator Carnival to supply the world's first LNG-powered cruise ships," Shell Integrated Gas & New Energies Director Maarten Wetselaar said. He said the future of transport fuels will show a new and evolving balance between different fuels, traditional and new, depending on customers' needs and local availability.

LNG Safety

LNG extraction falls under the oil and gas extraction subsector, where work related fatalities, injuries, and illnesses are lower than in years past but still hover to several deaths per year, according to the Bureau of Labor and Statistics. As LNG propels as the fuel of the future, companies will need to ensure they are following essential safety standards and remain efficient through focusing on process safety management.

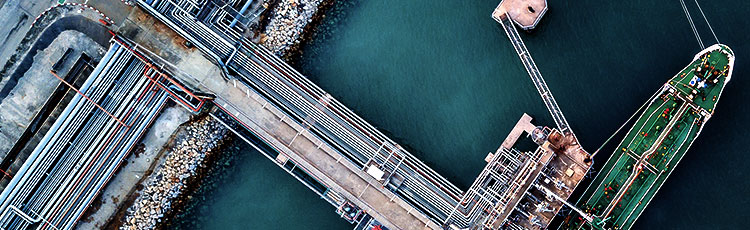

A critical part of process safety management is having the right tools in the right place for employees and contract workers in on- and offshore LNG facilities, terminals, and ships. Labels and signs reliably provide information such as hazard warnings, operating information, and safety reminders at the necessary locations. Reinforce clear communication by using:

- Thorough and consistent pipe marking and preventing leaking of hazardous materials

- General safety signs such as no smoking reminders and machine maintenance notifications during technical failures or breakdowns

- Floor marking throughout refinery facilities to demonstrate work boundaries and clearance areas

- Lockout/tagout for pressurized and heavy equipment

Quickly identify and assess risks that have the potential to become an incident, and take the necessary steps to mitigate or eliminate them for next-generation projects. Keep training up to date to ensure workers avoid dangerous ignition activities like working in confined spaces where vapors can accumulate. Review and improve emergency response tactics and procedures routinely focusing on cases of spills, fires, leaks, or explosions.

Related Resources

10 Safety Tips for Oil and Gas Industry Workers

Workers in the oil and gas extraction industry continue to be one of the highest at risk of injuries and ...

Read

OSHA's Process Safety Management Standard

OSHA established a Process Safety Management (PSM) standard that applies to all companies that use any one of ...

Read

Safety Risk Management

In our experience, those companies who place major significance on risk management are the most successful in ...

Read.png)