Maintain Uniformity with DoD Labels

When a business receives a contract to do work for the Department of Defense, keeping up with the proper labeling system is a crucial task. The information on how to label parts, items and even shipping boxes might seem confusing at first, but it is extremely important to follow orders to ensure organization and efficiency. Expectations are high when creating products or shipping freight for government or military destinations. Companies need trusted compliance education, tools, and services to help keep the job on the right track.

Keep Track

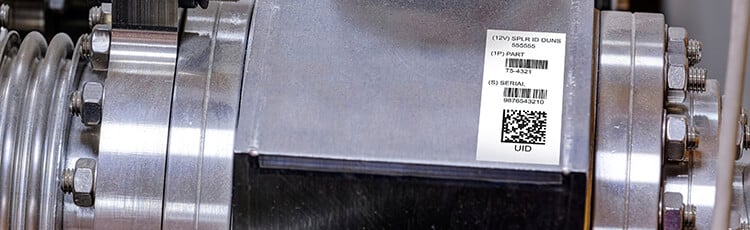

Any business supplying the DoD must follow proper procedures to maintain supply lines and inventories. For many of those situations, there are two parts to the procedures: MIL-STD-129R for shipping labels and the Item Unique Identification (IUID) system (MIL-STD-130) for asset management. These two systems are part of the same overall puzzle of logistics.

The ammunition and explosive section of the MIL-STD-129R standard for shipment and storage was completely rewritten in 2014, as new requirements were listed for the DoD's packaging label. This requirement helps keep shipment and storage of ammunition organized, providing the information that must be available for smooth transitions between contractors and the military.

The ammunition and explosive section of the MIL-STD-129R standard for shipment and storage was completely rewritten in 2014, as new requirements were listed for the DoD's packaging label. This requirement helps keep shipment and storage of ammunition organized, providing the information that must be available for smooth transitions between contractors and the military.

MIL-STD-129R shipping tag compliance includes proper barcoding, label materials, protection, and processing. This helps provide the DoD and all contractors that work with it a mechanism for tracking that box at all points, from the beginning of transit to final delivery. Make sure MIL-STD-129 and MIL-STD-130 labels are accurate for every container and pallet that needs to be sent.

"It's extremely important that our reporting is thorough because the more accurate we are, the more efficient our process is and the better business decisions we make," Dennis Zarnesky, director of Inventory Control Point (ICP), told Stripes Okinawa newspaper. He is part of a civilian based group that also includes retired military personnel. ICP uses a special digital program to track the proper issue, accountability, upkeep and disposal of ammo on a daily basis. The platform has transformed a once daunting task of sifting through thousands of transactions and records, to easily providing detailed information - down to the lot and serial number. "If there's an error at one of the 160 locations that track and disseminate ammo, the system can reveal that," Zarnesky said.

Worn, improperly created, or sloppy labels make the tracking of these items more difficult than necessary. Up until the release of better quality label materials and systems, military personnel were required to stencil tags. These labels have to comply with DoD requirements, but also with the requirements of shippers such as USPS. Create tags and labels with durable and compliant material and thermal print type to avoid wasting man hours filling out repetitive information.

"With modern shipping label requirements, logistics doesn't have as many issues as they used to," said Justin Davis, a logistics specialist and retired Marine who lives in Georgia. "The printed tags help multiple warehouses we were having issues with in being able to properly track the items they had within their warehouse. With the addition of the IUID, they were given a better way to manage the assets within the warehouse."

Command DoD Shipping

Managing military labeling compliance can be easier with tools developed specifically for the defense community. Design with confidence using tags and labels that comply with Department of Defense standards for materiel tracking, IUID labeling, and more. Companies can also benefit from using industrial-grade labeling systems and print-ready materiel condition tags.

Related Resources

GHS Label Information

Appendix C to the 2012 (OSHA 1910.1200) Hazard Communication Standard (HCS) specifies the mandatory ...

Read

Achieve IUID Compliance with Thermal Transfer Printing

What is the Goal of the IUID System? The Item Unique Identification (IUID) or MIL-STD-130 standard was ...

Read

What is HazCom? Your Guide to Chemical Labeling, GHS, & OSHA Standards

What Is HazCom? OSHA’s Hazard Communication Standard (HazCom) is a regulatory framework requiring chemical ...

Read.png)