Industry

Manufacturing

Challenge

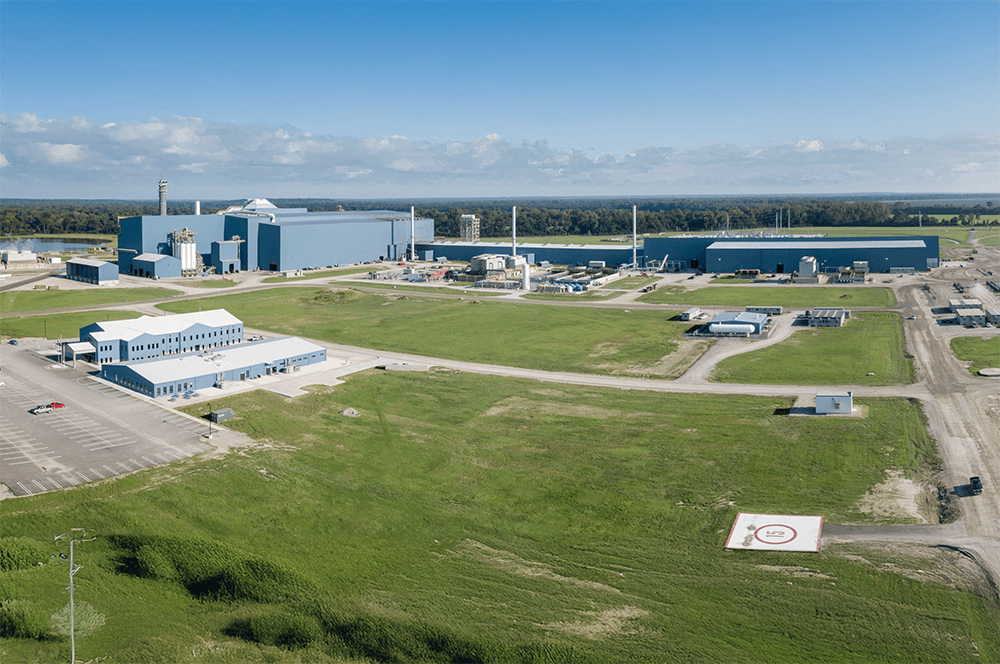

Ardagh Glass Packaging struggled with creating durable, large-format labels for safety, compliance, and asset management. Their lack of a reliable labeling system slowed processes and limited improvement projects like pipe marking and QR code implementation.

Results

DuraLabel Toro Max streamlined Ardagh’s labeling and improved productivity, safety, and compliance. The durable labels enhanced audits and asset tracking, allowing the plant to operate more efficiently and professionally.

Key Product

“I have used [the Toro Max Print System] for so many different products that help our employees keep things in order. We have had a few audits since we have had our labeler, and the auditors always comment on our labeling projects!”

Olivia Postlewait

The Challenge

At Ardagh Glass Packaging, maintaining and managing assets requires clear and durable labeling to support smooth operations and safety. Prior to adopting DuraLabel’s Toro Max, the team encountered significant challenges in completing labeling tasks.

Their previous labeler could not produce large, durable labels, which limited the company’s ability to complete small improvement projects effectively.

"Before we got our [DuraLabel] printer, we didn't have a labeler that would print large labels,” Postlewait described the difficulties: “This made it hard for us to complete small improvement projects like pipe marking, safety labels, and our QR code system."

The Solution

Ardagh Glass Packaging turned to DuraLabel and implemented the Toro Max Industrial Sign and Label Print System, which quickly solved their labeling challenges. The Toro Max allowed Postlewait and her team to print large, durable vinyl labels for various applications, including asset identification, pipe marking, and safety labeling.

One standout feature was the ability to create QR code labels for equipment. These QR codes, printed on premium vinyl, link employees to detailed equipment histories, for optimized asset management. “I use my DuraLabel Toro Max to print QR codes which make it easy for our employees to identify each asset along with the ability to scan the QR code and pull up the equipment history and information,” Postlewait explained.

The Toro Max's reliability and user-friendly design made it the go-to labeling tool for Postlewait's team of over ten employees.

“I use my DuraLabel Toro Max to print QR codes which make it easy for our employees to identify each asset along with the ability to scan the QR code and pull up the equipment history and information,” Postlewait explained.

The Results

DuraLabel Toro Max has significantly improved Ardagh Glass Packaging's labeling process. The durable vinyl labels have replaced paper stickers, ensuring that QR codes stay intact and readable over time. This enhanced the reliability of the asset tracking system, reducing the need for frequent replacements. “If I did not use this labeler for our QR code stickers, I would be using my normal printer to print QR codes on the paper stickers, which would not hold up like the vinyl labels you guys offer," Postlewait noted. The team also saved time by streamlining the labeling process, allowing them to focus on other critical tasks.

.png)