Industry

Energy

Challenge

Booth & Associates wanted to expand its services by offering arc flash hazard label printing alongside its arc flash studies. However, they had no existing process in place to handle this new offering efficiently.

Results

By bringing arc flash hazard label printing in-house, Booth & Associates streamlined compliance labeling for client projects. This eliminated the need for outsourcing, reduced turnaround times, and enhanced their ability to provide a full-service arc flash study and labeling solution.

Key Production

"John Hawks has been my representative and he has absolutely ensured success from day one!"

Kate Massey

Booth & Associates

The Challenge

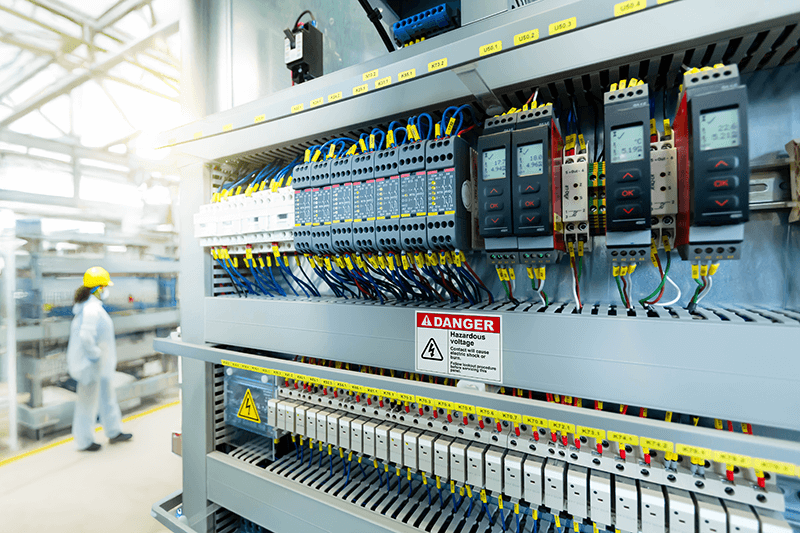

Arc flash hazard label printing was a new service for Booth & Associates. Before establishing an in-house process, the firm lacked a dedicated method for producing compliance labels for its clients. Relying on external providers led to delays, higher costs, and potential project slowdowns. To uphold its reputation for delivering top-tier electrical engineering services, Booth & Associates needed a reliable, user-friendly system for creating high-quality, compliant arc flash labels.

The Solution

With the help of the DuraLabel Toro Industrial Sign and Label Print System, Booth & Associates developed an in-house labeling process to meet their clients’ demand for compliant custom arc flash labels. This system enabled them to:

- Customize Arc Flash Labels for Each Project: Every label is tailored to the specific electrical system, voltage, incident energy, and required PPE, ensuring precise hazard communication.

- Enhance Compliance and Safety: Labels adhere to OSHA, NFPA 70E, and NEC guidelines, helping clients meet regulatory standards and improve workplace safety.

- Provide a Seamless Arc Flash Study & Labeling Service: Clients receive both comprehensive arc flash studies and the necessary hazard labels in one streamlined package, reducing delays and ensuring consistency.

- Improve Efficiency and Accuracy: By keeping labeling in-house, Booth & Associates maintains full control over label quality and ensures that critical safety information is clearly conveyed.

- Offer Long-Lasting, Durable Labels: The in-house process ensures that labels are resistant to harsh environments, including heat, chemicals, and abrasion, preserving safety information over time.

"I am able to print customized arc flash hazard labels for a variety of projects for our clients, allowing us to better serve them and not have to go elsewhere for their label printing needs." – Kate Massey

The Results

Since implementing in-house arc flash hazard label printing, Booth & Associates has successfully incorporated compliance labeling into its range of client services. By keeping the entire process internal, the company has improved efficiency, eliminated outsourcing delays, and added value to clients by offering a complete arc flash study and labeling solution. As a result, Booth & Associates has strengthened client relationships, enhanced its service offerings, and ensured that clients receive accurate, regulation-compliant labels for their projects.

.png)