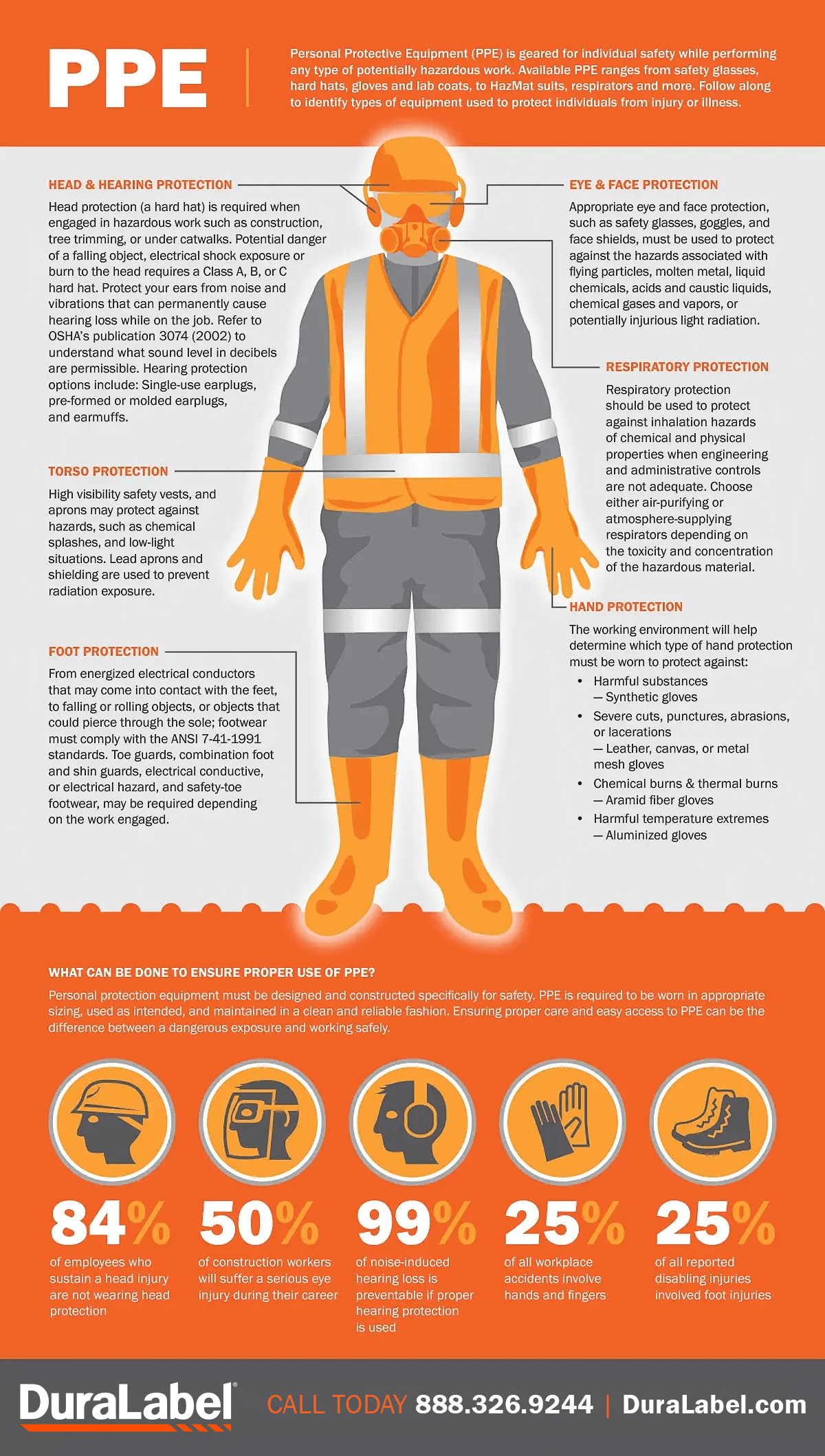

PPE

Infographic Transcription

Personal Protective Equipment (PPE) is geared for individual safety while performing any type of potentially hazardous work. Available PPE ranges from safety glasses, hard hats, gloves and lab coats, to HazMat suits, respirators and more. Follow along to identify types of equipment used to protect individuals from injury or illness.

HEAD & HEARING PROTECTION

Head protection (a hard hat) is required when engaged in hazardous work such as construction, tree trimming, or under catwalks. Potential danger of a falling object, electrical shock exposure or burn to the head requires a Class A, B, or C hard hat. Protect your ears from noise and vibrations that can permanently cause hearing loss while on the job. Refer to OSHA’s publication 3074 (2002) to understand what sound level in decibels are permissible. Hearing protection options include: Single-use earplugs, pre-formed or molded earplugs, and earmuffs.

EYE & FACE PROTECTION

Appropriate eye and face protection, such as safety glasses, goggles, and face shields, must be used to protect against the hazards associated with flying particles, molten metal, liquid chemicals, acids and caustic liquids, chemical gases and vapors, or potentially injurious light radiation.

RESPIRATORY PROTECTION

Respiratory protection should be used to protect against inhalation hazards of chemical and physical properties when engineering and administrative controls are not adequate. Choose either air-purifying or atmosphere-supplying respirators depending on the toxicity and concentration of the hazardous material.

TORSO PROTECTION

High visibility safety vests, and aprons may protect against hazards, such as chemical splashes, and low-light situations. Lead aprons and shielding are used to prevent radiation exposure.

HAND PROTECTION

The working environment will help determine which type of hand protection must be worn to protect against:

• Harmful substances

— Synthetic gloves

• Severe cuts, punctures, abrasions, or lacerations

— Leather, canvas, or metal mesh gloves

• Chemical burns & thermal burns

— Aramid fiber gloves

• Harmful temperature extremes

— Aluminized gloves

FOOT PROTECTION

From energized electrical conductors that may come into contact with the feet, to falling or rolling objects, or objects that could pierce through the sole; footwear must comply with the ANSI 7-41-1991 standards. Toe guards, combination foot and shin guards, electrical conductive, or electrical hazard, and safety-toe footwear, may be required depending on the work engaged.

WHAT CAN BE DONE TO ENSURE PROPER USE OF PPE?

Personal protection equipment must be designed and constructed specifically for safety. PPE is required to be worn in appropriate sizing, used as intended, and maintained in a clean and reliable fashion. Ensuring proper care and easy access to PPE can be the difference between a dangerous exposure and working safely.

84%

of employees who sustain a head injury are not wearing head protection

50%

of construction workers will suffer a serious eye injury during their career

99%

of noise-induced hearing loss is preventable if proper hearing protection is used

25%

of all workplace accidents involve hands and fingers

25%

of all reported disabling injuries involved foot injuries

DuraLabel®

CALL TODAY 888.326.9244 | DuraLabel.com

.png)