3D Printing Hazards

3D printing, or additive manufacturing (AM), is a popular method for rapid prototyping and even small-scale manufacturing. Compared to CNC milling or casting, 3D printing is relatively fast and inexpensive. 3D printing allows engineering teams to employ the principle of "Fail Fast, Fail Cheap" for product concepts. To accelerate learning, elements of a mechanical project are printed early for performance and usability tests.

Harmful Effects of 3D Printing

3D printers use a variety of materials from thermoplastic filament to powdered metal to concrete. Many materials have hazards associated with them that users should be aware of and trained to handle.

Most common 3D printing processes use a thread like plastic filament (called feedstock) that is liquefied via a heating element and which is then jetted through a nozzle. Prolonged exposure to fumes from some materials can be hazardous. Recent studies of 3D printers and thermoplastic feedstock have found hazardous vapors and gases are emitted during the printing process. The two most popular thermoplastics used, ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), have been found to release ultrafine particles (UFP) and volatile organic compounds (VOCs).

UFPs, or nanoparticles, are particles between 1 and 100 nanometers in size (1 x 10-9 m). These are the same dimensions of biological molecules which mean they can be immediately absorbed by living systems. Reports say that inhaled nanoparticles can reach the blood, liver, and heart. Exposure to nanoparticles at high concentrations is associated with adverse health effects.

VOCs are organic chemicals that have a high vapor pressure at room temperature. The high-pressure nature means that large numbers of molecules are able to evaporate and enter the surrounding air. We are exposed to VOC pollutants in many ways every day from air fresheners to gas engine emissions. Studies of the materials used for 3D printing, such as ABS, PLA, and nylon can be a source of dangerous VOCs such as styrene, butanol, cyclohexanone, ethylbenzene, and others. In particular, heating ABS at a temperature typical for 3D printing results in high VOC emission. A study found that the particle concentration of ABS material was 33?38 times higher than PLA material. Health effects from VOC emissions include eye, nose, and throat irritation, nausea, and organ damage.

3D Printing Safety with VOC, ABS and PLA Fumes

The good news is that emission exposure can be avoided with good ventilation. The University of Florida?s 3D Printer Policy allows one printer per standard office and no more than two printers for a standard classroom or workroom. The 3D Printing Safety fact sheet (PDF) from Carnegie Mellon University recommends that air volumes should be replaced four times per hour.

3D printed parts are built layer by layer. Each layer supporting the next. To model complex shapes, 3D printers employ support structures that are dissolved away after the print completes. Alkaline baths are often used to dissolve support materials. The bath is usually water and caustic soda (sodium hydroxide). Caustic soda is corrosive and can cause chemical burns, scarring, and blindness. Proper handling, spill, and waste disposal precautions are necessary to safely handle alkaline baths.

Advanced industrial 3D printers employ gas atomized metal powder for applications within the aerospace, medical, and tooling industries. Metal powders can be flammable. Labs handling this material should use proper personal protective equipment (PPE), anti-static measures, and fire suppression equipment.

Safety and 3D Printing

Duralabel provides numerous resources to help engineering labs operate safer. Visual communication, PPE, and spill control equipment can help staff stay safe around 3D printers and the hazardous chemicals used to dissolve support materials.

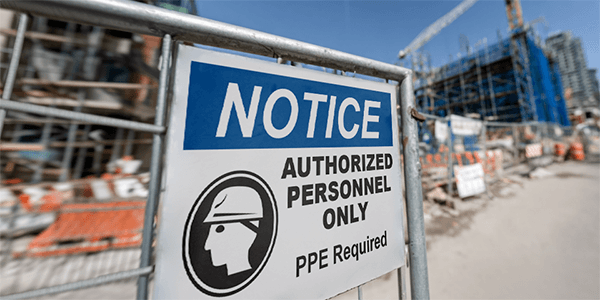

- Safety signs and labels posted on and nearby printers should warn of emissions and hot surfaces. HVAC controls for ventilation should indicate the requirements for indoor air quality. Signs should indicate the location of fire extinguishers, eyewash stations, feedstock and chemical storage, and clean up supplies. In labs that employ anti-static measures, labeling equipment with a label that has anti-static properties like DuraLabel Electrostatic Dissipative Tape (ESD) will help avoid static buildup. For more information about safety signs for the workplace, see the Best Practice Guide to OSHA Safety Signs.

- Floor marking tape installed around printer or alkaline baths indicate hazardous areas to laboratory staff. Learn more about products for durable floor marking.

The following 3D printing precautions were collected from the recommendations published by Carnegie Mellon University, University of Florida, and University of Vermont:

- Consult the Safety Data Sheets (SDSs) of printing materials

- Provide OSHA safety training to individuals that work with hazardous 3D printer chemicals

- Provide training in the correct and safe operation of the 3D printer

- Use 3D printers in a well-ventilated area

- When using metal materials keep workspaces free of any static electricity

- Do not open 3D printer covers once a print job is underway

- Equip the facility with Class D fire extinguishers and train on proper use

- Wear a protective P100 respirator dust mask when accessing the printer stage area

- Handle uncured printing materials with neoprene or nitrile gloves

- For print processes that use an alkaline bath to dissolve support material, provide an emergency eyewash station in the immediate vicinity of the work

- Wear eye protection around liquid materials that can splash

- Use solvent-absorbent pads for spills of printing material

- Keep model and support materials away from areas where food and drink is stored, prepared, or consumed

Related Resources

New Safety Controls Expand As Industrial Laser Use Grows

Laser use in industry has seen a sharp increase in the past year and the technology is being used for a ...

Read

Industrial Safety Labels | Label Signage | Sign Label

The accurate interpretation of safety signs is crucial to prevent injuries and save lives. OSHA has set ...

Read

5 Industries that Benefit from Custom Industrial Safety Signs and Why

Why Are Custom Industrial SafetySigns Essential for Protecting Workers? In every high-risk workplace, silent ...

Read.png)