Arc Flash Safety in the Workplace: 5 Mistakes to Avoid

How Can Arc Flash Risks Be Identified?

Arc flash risks can be identified by evaluating electrical systems, work tasks, and equipment conditions before work begins. Facilities should conduct a formal arc flash hazard analysis to determine incident energy levels, approach boundaries, and required personal protective equipment.

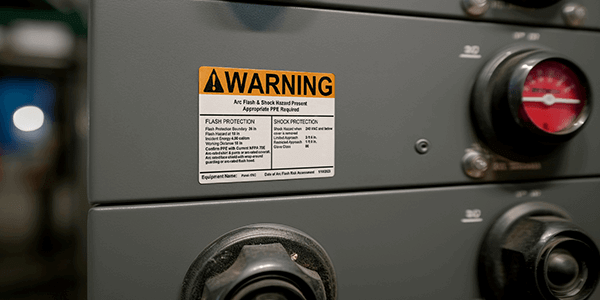

Regular inspections help uncover risk factors such as aging equipment, damaged components, poor maintenance, or changes to electrical systems that may increase arc flash exposure. Clear arc flash labels, up-to-date diagrams, and documented procedures allow workers to recognize hazards quickly and follow arc flash safety and electrical safety best practices before performing energized work.

What is an Electrical Arc Flash?

An electrical arc flash is a sudden burst of electrical energy that creates intense heat and light capable of causing severe injuries and equipment damage. The phenomenon occurs in a fraction of a second but can have permanent consequences for a worker’s life.

Addressing this hazard takes skill, responsibility, and consistent safety practices, often requiring the use of electrical safety printers to produce durable hazard communication. Workplaces can strengthen arc flash safety and support arc flash prevention by avoiding these common mistakes and printing custom safety signs that undermine compliance and awareness.

Common Electrical Arc Flash Mistakes That Undermine Arc Flash Safety

Understanding how electrical arc flash incidents occur is the first step in preventing them. These key points outline where even experienced teams can slip up and how to strengthen electrical safety in daily operations using electrical safety best practices.

1. Failing to Control Hazardous Energy

Every strong electrical safety program begins with controlling hazardous energy, often utilizing a Bronco Max printing system to ensure lockout/tagout (LOTO) procedures are clearly labeled. When steps are skipped, the risk of an electrical arc flash incident increases dramatically.

Complacency can cause workers to bypass critical procedures like lockout/tagout (LOTO). An efficient LOTO program should include steps to follow before, during, and after work is complete. For electrical work, it should also follow the National Fire Protection Association (NFPA) 70E guidelines—one of the most important electrical safety best practices for energized work.

What is NFPA 70E? The NFPA 70E standard covers shock and flash boundaries and provides tables for common situations to help workers establish electrical safety in the workplace and strengthen arc flash prevention.

2. Outdated Arc Flash Analysis Increases Risk

As systems age and equipment changes, so should a facility’s arc flash analysis. Outdated data can create false confidence, putting workers at risk of an electrical arc flash.

An arc flash hazard analysis, using standardized steps, is fundamental to working safely on energized equipment. You may follow the NFPA 70 standard, or you can follow the more calculated IEEE 1584 standard. The IEEE 1584 standard offers an experimentally-derived calculation method. Even with these accepted standards, science is still improving, and professionals need to be aware of potential pitfalls.

"My major concern with the way arc flash analysis is done by most folks is that heat flux is not factored in when determining threshold incident energy to second-degree burn," said Michael Furtak, a certified engineering technologist and editor of ArcAdvisor.com.

OSHA's regulations provide the minimum acceptable arc flash requirements. For optimum electrical safety, workers should look beyond those requirements. For optimal arc flash safety, workers should look beyond those minimums to support full protection and long-term arc flash prevention.

3. Poor Maintenance Creates Hidden Arc Flash Hazards

Even well-designed systems fail when maintenance is neglected. Small mechanical issues can build into serious electrical arc flash hazards if not addressed in time.

As part of vigilant housekeeping, facilities should routinely evaluate electrical components and equipment for age, damage, and proper function. Many common pieces of equipment need periodic maintenance, which often is forgotten or ignored. Not only could sticky switches, old control panels, and loose wires be a potential arc flash hazard, they can also cause fires, short circuits, and other equipment failures.

Routine inspection and preventive maintenance not only reduce these risks but also support long-term compliance and reliability—core electrical safety best practices that strengthen arc flash safety.

4. Lack of Training and Experience Among Workers

Strong equipment and processes mean little without knowledgeable workers. Lack of training is one of the most common contributors to electrical arc flash injuries.

Continuous arc flash incident training is important for any industry. Make sure electrical assessments, maintenance procedures, diagrams, and equipment specifications are up to date and easily accessible for the types of work that will be done. Make sure all workers are aware of high-voltage areas, electrical substations, and underground utility lines.

Ensure all workers are aware of high-voltage areas, electrical substations, and underground utility lines. Communicate critical information through clear signs, labels, and visual training materials. Before any live work begins, ensure all affected employees review the energized electrical work permit. This helps workers confirm PPE requirements, understand hazards, and voice concerns before starting any high-risk tasks—an essential step for arc flash prevention.

A DuraLabel industrial label printer can be a very useful tool when creating tags that meet these arc flash requirements. In particular, the Toro Max and Kodiak Max can produce the right size, the right color labels, and meet the durability requirements—supporting arc flash safety at the point of use.

5. Improper PPE Selection and Poor Safety Communication

Even the best prevention programs fall short without the right protection and communication. PPE serves as the final safeguard when all other controls fail.

While personal protective equipment is the last line of defense for an arc flash incident, it's necessary to protect workers from electric shock and burns. Be sure it meets or exceeds the minimum arc rating (AR) for the situation, as assessed by your arc flash hazard analysis, and posted on your arc flash labels.

Labels and signs also play a vital role in reinforcing electrical safety. Mark arc flash boundaries and electrical control panel clearances using floor tape and high-visibility signage to communicate hazards at the point of contact.

DuraLabel Resources to Amplify Arc Flash Safety

Effective prevention depends on consistency. Building a safer workplace means combining reliable communication tools with an informed workforce.

Workplaces of all sizes can improve arc flash safety programs with a few simple updates. Defending against electrical arc flash hazards requires clear communication, durable labeling, and a commitment to continuous improvement.

Employers can improve their workplace arc flash safety signage with expert help from DuraLabel’s portable label printer Toro Max. It gives you the freedom to create signs compliant with industry standards and design custom labels to meet site-specific needs.

Whether you need safety signs, pipe markers, or equipment labels—the DuraLabel® Toro® Max Industrial Sign and Label System is ready to transport anywhere you are. Get help crafting a system that will provide the safety communication you need. Call 1-888-788-9936 and one of our experts will guide you through the process.

Learn more about electrical safety with the free DuraLabel Electrical Safety Quick Start Guide. This guide will improve your warehouse electrical safety by meeting OSHA/NFPA arc flash requirements and utilizing visual communication. Download our free guide on electrical safety below.

Read Next:

Related Resources

Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary? An arc flash protection boundary defines the minimum safe distance ...

Read

Strengthen Electrical Safety Through Effective Arc Flash Training

What Electrical Safety Hazards Put Workers at Risk? Electricity powers the modern workplace. Motors, ovens, ...

Read

How to Improve Arc Flash Hazard Safety in Mining Operations

How Can Mining Teams Reduce the Risk of Arc Flash Hazards? Mining operations depend heavily on electrically ...

Read.png)

.webp)

%20(1).webp)