Arc Flash PPE: What Workers Need to Know

Arc flash PPE safety image showing an electrical worker wearing a full flash suit with face shield for NFPA 70E-compliant protection against high-voltage arc flash and shock hazards.

Why Does Arc Flash PPE Matter for Worker Safety?

Personal Protective Equipment (PPE) is the last line of defense against injuries. When it comes to arc flash protection, PPE is necessary to protect workers from electric shock and burns. Fortunately, NFPA 70E offers guidance for understanding arc flash PPE and choosing the right gear for the job - a necessity highlighted by any arc flash survivor story.

Arc Flash PPE Overview

PPE designed to protect against arc flash hazards is called arc-rated (AR) clothing. AR clothing has been tested against exposure to an electric arc, and its AR rating (expressed as a number) represents the amount of incident energy the clothing can block or absorb. Note that older PPE may be marked as flame-resistant (FR), which is not the same; all arc-rated equipment is also flame-resistant, but not all flame-resistant equipment is also arc-rated.

Depending on the hazards, workers may be required to wear as little as a long-sleeve shirt and pants made from untreated natural fiber, or as much as a full arc flash suit over other protective clothing. Using the right arc flash equipment is critical to maintaining safety in environments where electrical energy is present.

None of the clothing worn next to a worker's skin should include materials that may melt, such as nylon or acetate. If these materials are exposed to the extreme heat of an arc flash, they can melt onto a worker's skin and remain, causing extreme burns. Natural fibers (such as cotton) are the best choice for these underlayers.

While AR equipment is meant to protect workers from burns, arc flash protection also involves addressing other hazards: powerful blasts of pressure, loud bursts of sound, and sprays of molten metal or shrapnel. As such, additional arc flash equipment may be needed to keep workers safe from secondary injuries.

Determining Appropriate PPE Levels

Wearing too little PPE can expose a worker to lethal injuries. On the other hand, highly protective PPE can be bulky and uncomfortable, restrict a worker's vision and movement, and increase the chance of an accident.

NFPA 70E offers two methods for finding the right PPE for working on a given set of equipment:

- Incident Energy Analysis: The expected incident energy of an arc flash is calculated for each piece of equipment, according to its actual installation. The incident energy is then used to determine how much protection a worker would need.

- Arc Flash PPE Categories: Each piece of equipment is found on a set of tables in the standard. The tables assign one of four categories to the equipment, with each category requiring a specific set of PPE and having a minimum arc rating for the clothing to be worn.

The PPE tables provided in NFPA 70E are valid only for a limited range of equipment and installations. Where the equipment or installation does not match one of the tables' entries, you should conduct an incident energy analysis.

Arc Flash PPE Chart

Understanding Arc Flash PPE Categories

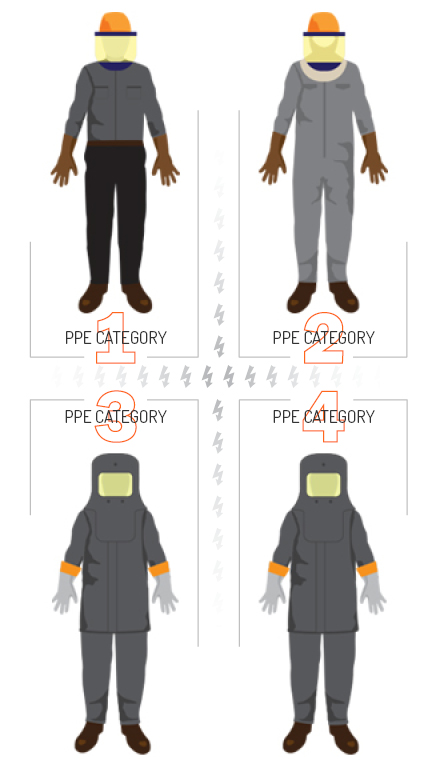

If you use the NFPA's tables to find PPE recommendations, the result will be one of four category numbers, corresponding to a standardized set of equipment.

Each category includes a minimum arc rating (AR) value for each piece of equipment; the AR is determined by the PPE manufacturer and reflects the amount of heat energy that the PPE can absorb or block before the worker is likely to sustain second-degree burns.

Categories 1 and 2 usually require only a single layer of arc-rated PPE, while categories 3 and 4 usually mandate multiple layers of arc flash equipment for higher levels of protection.

| PPE Category | Minimum Arc Rating (cal/cm²) | Typical Protection Level | Common PPE Components |

|---|---|---|---|

| Category 1 | 4 cal/cm² | Lower exposure risk | Arc-rated shirt and pants, face shield, gloves |

| Category 2 | 8 cal/cm² | Moderate exposure risk | Arc-rated shirt and pants, arc-rated face shield or hood, gloves |

| Category 3 | 25 cal/cm² | High exposure risk | Arc-rated flash suit, hood, gloves, balaclava |

| Category 4 | 40 cal/cm² | Very high exposure risk | Full arc flash suit, hood, multi-layer protection |

The arc rating is determined by the PPE manufacturer and reflects how much heat energy the equipment can withstand before second-degree burns are likely.

See the types of arc flash PPE that correspond with each category in DuraLabel' free Arc Flash PPE Quick Reference Guide.

Arc flash PPE categories chart illustrating NFPA 70E PPE Category 1–4 protection levels, from basic FR clothing to full flash suits with hood, gloves, and face shield for electrical hazard safety.

Arc Flash PPE Labels and Signage

Whatever method is used to decide the appropriate level of PPE, that information must be posted on or near the equipment with an informative arc flash label. NFPA 70E includes specific requirements for these equipment labels in Article 130.5(D); one such requirement is to display PPE information. This information should appear using at least one of the following four methods:

- Incident Energy and Working Distance: If an Incident Energy Analysis has been performed, the results of that analysis can provide detailed information on the amount of heat energy that workers need to protect themselves from. Because the effective Incident Energy decreases dramatically as a worker's distance from the equipment increases, it's important to specify which Working Distance was used for the calculations.

- Arc Flash PPE Category: If the NFPA's tables cover the equipment in your facility, this approach offers a simple shortcut. Each of the numbered categories, from 1 to 4, refers to a specific set of equipment. To avoid confusion and possible contradiction, the Incident Energy and the Arc Flash PPE Category should not be used for the same equipment.

- Minimum Arc Rating for Clothing: This approach effectively tells workers how much protection they need, which can simplify the process of job-to-job PPE selection. Every piece of arc flash PPE will be clearly marked by the manufacturer with its arc rating; workers simply need to match their PPE with the label, and wear arc flash equipment that meets or exceeds this required protective value.

- Site-Specific PPE Identification: Where another approach makes sense for a facility, the NFPA offers this option. Some sites use a full listing of the different PPE elements required for safe work, while others use a customized or color-coded system, such as "Blue Suit with Hood." With this approach, it's critical to maintain effective employee training to ensure workers understand the system in place.

These labels or signs must be legible and durable, standing up to whatever environment they are in. The DuraLabel line of printers from DuraLabel offers a simple and reliable way to make these labels on-site and on-demand.

Thinking beyond Arc Flash PPE

PPE can greatly reduce the injuries associated with an arc flash event, however the best way to reduce injuries is to prevent them altogether.

Whether you need safety signs, pipe markers, or equipment labels—Toro Max is ready to transport anywhere you are. Get help crafting a system that will provide the safety communication you need. Call 1-888-789-9790 and one of our experts will guide you through the process.

Learn more about establishing and reinforcing industry best practices for arc flash PPE. It gives you the information and tools needs to prevent accidents at your workplace. Download our free Arc Flash Labeling Guide

Read Next:

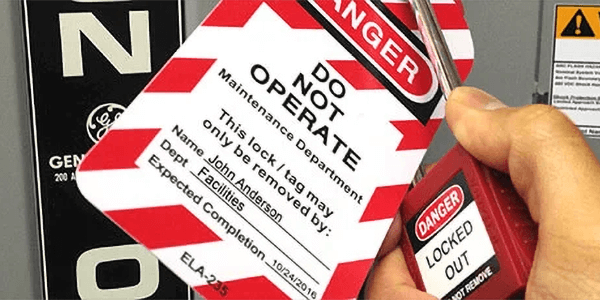

Importance of Lockout/Tagout Training

Related Resources

NFPA 70E Arc Flash with OSHA Signs

What is NFPA 70E? NFPA 70E, or the NFPA’s Standard for Electrical Safety in the Workplace, outlines specific ...

Read

Electrical Safety Gap Analysis: OSHA and NFPA 70E Safety Standards

Why Is an Electrical Safety Audit Critical for Workplace Compliance? No electrical system is without gaps. ...

Read

How to Prevent Arc Flash with Lockout/Tagout Signs and Safety Labels

What Are the First Steps to Preventing an Arc Flash Accident in the Workplace? In the realm of electrical ...

Read.png)

%20(1).webp)