8 Essential HVAC Installation Tips to Prevent Costly Mistakes

.png)

HVAC Installation Done Right: 8 Essential Tips to Prevent Costly Mistakes

A poorly installed heating, ventilation, and air conditioning (HVAC) system does not just underperform—it can cost businesses thousands in repairs, energy inefficiencies, and lost productivity. Every year, improper sizing, faulty ductwork, and overlooked safety measures lead to system failures that could have been avoided.

According to the Sheet Metal and Air Conditioning Contractors' National Association (SMACNA), energy loss from defective duct systems can reach up to 40%, significantly increasing operational costs. Additionally, the Occupational Safety and Health Administration (OSHA) reports that HVAC-related indoor air quality issues affect over half of commercial buildings, impacting both employee productivity and overall health.

Improper HVAC installation can lead to increased operational costs, energy inefficiencies, and premature system failures. To prevent costly mistakes and ensure compliance with industry standards, HVAC contractors should follow these eight essential steps:

1. Avoid Sizing Errors

Selecting the right HVAC unit size is crucial for efficiency and performance. Undersized systems struggle to meet demand, running excessively and wearing out prematurely. Oversized systems cycle on and off frequently, resulting in inconsistent temperatures and wasted energy.

The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) Standard 90.1-2022 establishes energy efficiency requirements, including proper load calculations to ensure HVAC systems operate at optimal performance. HVAC contractors determine the right system capacity by performing load calculations that consider square footage, insulation, and climate.

Improper sizing also impacts humidity control, increasing the risk of mold growth and indoor air quality issues. The Energy Star program recommends professional load calculations to prevent these inefficiencies. In fact, poor sizing remains a primary reason HVAC systems fail to meet energy efficiency standards, further raising operational costs.

2. Install Ductwork Correctly

Ductwork directly affects HVAC efficiency. Poorly sealed or inadequately insulated ducts waste energy, strain the system, and drive-up operational costs. ASHRAE Standard 90.1 sets guidelines for minimizing duct leakage through proper sealing and insulation, ensuring efficient airflow and reduced energy loss.

Common ductwork mistakes, such as using the wrong materials, failing to seal joints, and adding unnecessary bend, can reduce airflow and overall performance. Ensuring a proper design, secure connections, and adequate insulation optimizes energy use and extends system lifespan.

According to the U.S. Department of Energy, sealing and insulating ducts effectively can enhance energy efficiency by up to 20%. This reduces the load on the HVAC system, lowers energy costs, and minimizes the need for frequent maintenance.

3. Maintain Accurate Refrigerant Levels

Accurate refrigerant charging keeps HVAC systems running efficiently. Overcharging increases system pressure, leading to component failure, while undercharging diminishes cooling effectiveness and damages the compressor. Contractors must follow manufacturer specifications and use proper instrumentation to prevent these issues.

The Environmental Protection Agency (EPA) enforces regulations on refrigerant handling to reduce environmental impact. HVAC contractors must comply with EPA Section 608, which mandates proper measurement and leak prevention.

4. Prevent Drainage Issues

Adequate drainage is essential for maximizing the lifespan of HVAC systems. HVAC condensation must drain properly to prevent leaks, mold growth, and water damage.

Clogged or misaligned drain lines can lead to water buildup, reducing system efficiency and result in costly repairs. To avoid these issues, contractors should install accessible, well-maintained drainage systems to ensure smooth operation and long-term performance.

5. Ensure Secure Electrical Connections

Faulty electrical connections contribute to HVAC system failures. Loose wiring, improper voltage, and unsecured connections can create fire hazards and operational inefficiencies. Contractors must follow electrical codes, verify voltage compatibility, and securely fasten all connections.

Labeling electrical components helps prevent errors and optimize troubleshooting. Clearly labeled wiring, control panels, and circuit breakers improve HVAC electrical safety, simplify maintenance, and reduce repair time.

6. Trouble Shoot and Calibrate the System

Skipping system testing and calibration often leads to overlooked performance issues. Trouble shooting can confirm adequate airflow, detect leaks, verify thermostat accuracy, and confirms seamless component operation. Routine calibration optimizes efficiency and helps prevent potential failures and unnecessary downtime.

Consistent system testing and clear HVAC system labeling best practices contribute to long-term operational success. Labels also help track maintenance schedules, reducing unexpected breakdowns and reinforcing compliance with safety standards.

7. Follow Manufacturer Guidelines

Every HVAC system includes manufacturer guidelines that outline proper installation procedures. Ignoring these instructions can void warranties, reduce efficiency, and shorten the lifespan of the system.

HVAC contractors must follow all manufacturer specifications, including mounting procedures, operational settings, and regulatory requirements to ensure optimal performance and compliance.

8. Use Labels and Signage to Improve Efficiency and Safety

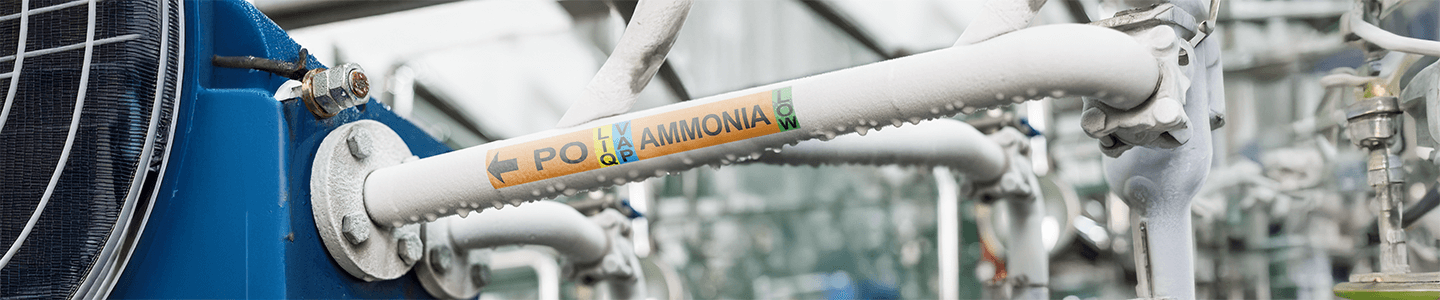

Signs and labels keep HVAC installations organized and help reduce costly errors. Mislabeled or unmarked components can lead to downtime, repairs, and safety risks. By clearly marking wiring, refrigerant lines, shut-off valves, and hazardous areas, contractors can simplify installation and maintenance while improving workplace safety.

OSHA mandates clear signage in mechanical rooms and high-voltage areas to prevent workplace injuries. Labels identify potential hazards, guide technicians through troubleshooting, reduce guesswork, and reduce error-prone handling.

Investing in durable, high-visibility labels improves efficiency and compliance by ensuring that all components are easy to locate and service. Date-stamped inspection labels allow contractors to keep accurate records of completed work, reducing the risk of missed servicing.

DuraLabel HVAC Labeling Resources

Clear, accurate labeling helps contractors organize HVAC systems, reduce troubleshooting time, and maintain compliance with safety regulations. Properly marked wiring, refrigerant lines, and shut-off valves improve efficiency and minimize errors during installation and maintenance. Labels also help simplify routine inspections, making servicing equipment faster and more efficient.

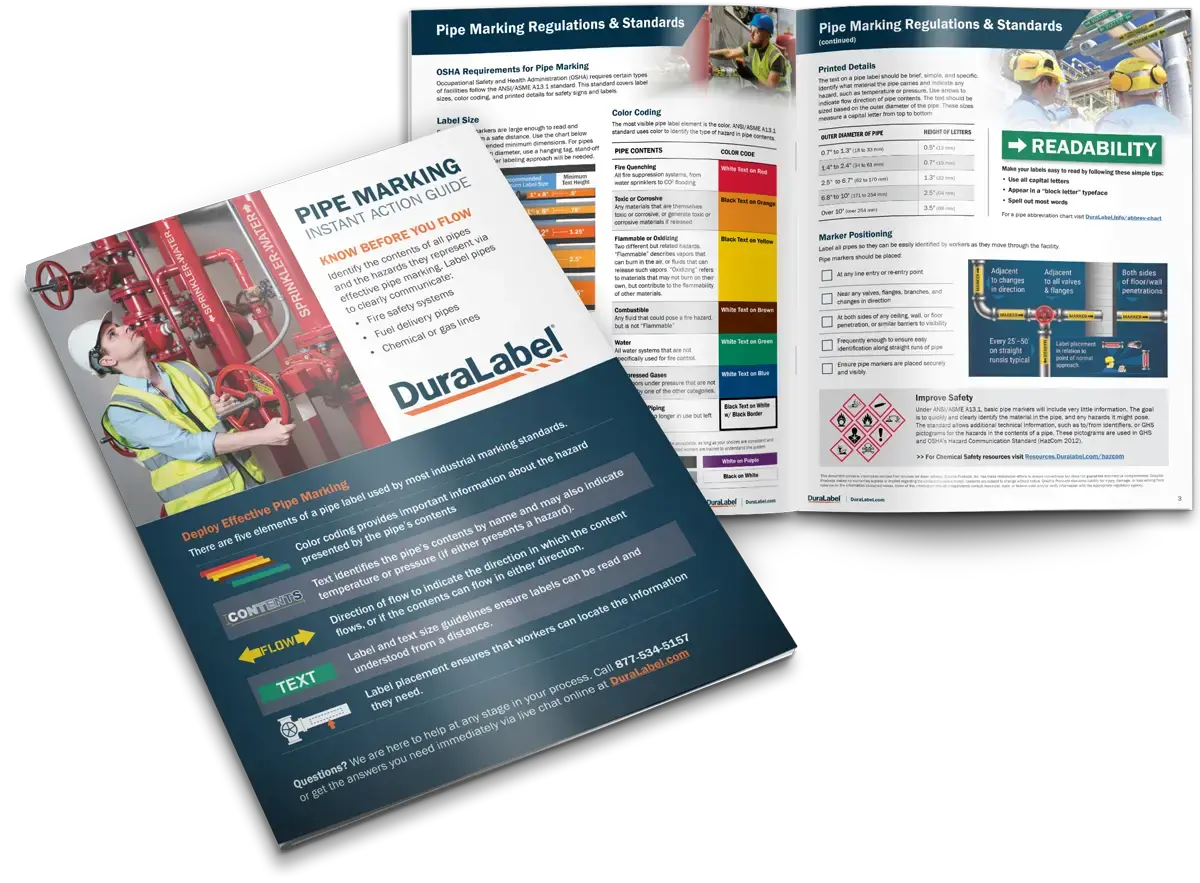

DuraLabel’s free Pipe Marking Quick Start Guide helps industrial professionals implement effective pipe labeling in HVAC and mechanical systems. This guide outlines key requirements from ANSI/ASME A13.1, including best practices for pipe labeling, color standards, and placement recommendations to improve workplace safety and compliance. Download your free copy today.

Get started with DuraLabel’s HVAC Labeling Quick Start Guide. This free guide helps you label ducts, pipes, and panels to meet OSHA, NFPA, ANSI/ASME, and IIAR standards. Learn how to choose durable materials, prevent accidents with clear labeling, and improve system efficiency. Stay safe, compliant, and confident in your HVAC labeling strategy.

Need assistance with your pipe labeling? Call 1-888-789-9790 and a safety professional will guide you through the process.

Read Next:

Pipe Marking: A Safety Tool Worth Examining

Pipe Marking Basics: OSHA & ANSI/ASME Labeling Standards

Related Resources

What New HVAC Codes Means for A2L Refrigerant Regulations

What Are A2L Refrigerants? A2L refrigerants are a class of chemicals defined by ASHRAE Standard 34 as having ...

Read

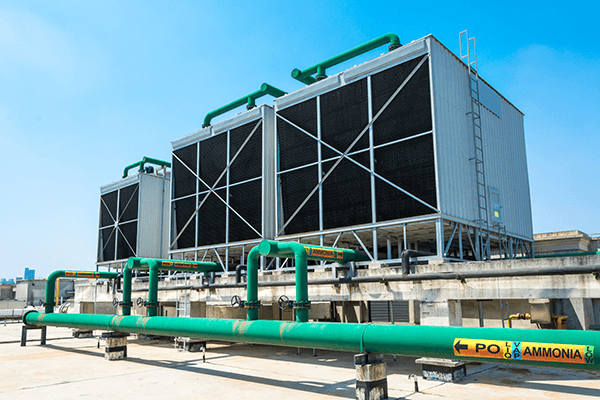

Ammonia Refrigeration Safety Fundamentals: Pipe Marking and Beyond

Artificial cooling systems keep industry running, and many of these systems use anhydrous ammonia as a ...

Read

Modern HVAC Safety and Efficiency Essentials

The heating, ventilation, air conditioning, and refrigeration industry is heating up as demand grows, new ...

Read.png)