Continuous Improvement Ideas for the Workplace

Success in today's competitive market requires constant innovation and a vision focused on continuous improvement. When first considering continuous improvement, it can be hard to know where to start, but here are some helpful tips that should make it easier.

Before You Begin

To start, you need to select the right continuous improvement tool for your business's needs. This will help you receive the greatest benefit and increase the likelihood that your program will last.

Continuous improvement includes tools like 5S, Kanban, and Total Productive Maintenance (TPM). Each tool provides specific benefits and can help improve efficiency, reduce costs, and increase quality. Among these tools, 5S is one of the easiest to start with because it can be implemented quickly, in every aspect of the business.

Using 5S as Your Continuous Improvement Tool

Using 5S as Your Continuous Improvement Tool

Part of what makes 5S one of the best tools to start with is that it has very clear steps that can be implemented without coming up with a complicated plan or identifying cell production rates. This is possible because of the five sequential steps that form the 5S system: Sort, Set in Order, Shine, Standardize, and Sustain.

Sort helps you remove clutter by identifying items that don't belong or are no longer used. This frees up space, improving workflow and efficiency.

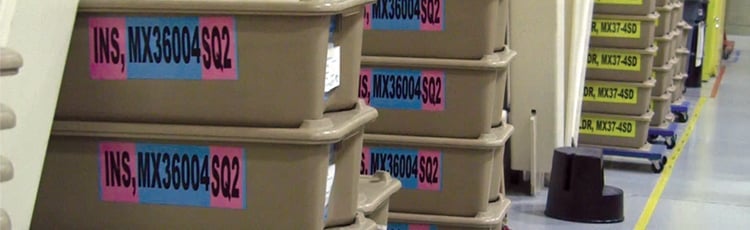

Set in Order adds efficiency by creating a place for every item based on use and function. Tools and supplies are easy to find because they are labeled so everyone knows where they belong.

Shine requires everything to be restored to a like-new condition. This step helps operators keep equipment running smoothly and spot issues that may have been hidden by grime or dirt.

Standardize helps to address common efficiency and quality issues caused by doing the same thing more than one way. In this step, workers standardize how tasks are performed as well as how each work area is organized.

Sustain ensures that your program will continue each day. In this step, you repeat each step in 5S to maintain improvements.

Next, you need to prepare your workforce by training them about continuous improvement and the tool you selected. Helpful resources like the Best Practice Guide to 5S by Duralabel can help you prepare your workforce by explaining the fundamentals of 5S, providing helpful training tools, and showing how 5S can be implemented from start to finish.

Ideas for Getting Started

Let's say you chose 5S as your continuous improvement tool and have prepared your workforce. It's now time to begin by choosing a starting point in your workplace. An area will be a good candidate if:

Let's say you chose 5S as your continuous improvement tool and have prepared your workforce. It's now time to begin by choosing a starting point in your workplace. An area will be a good candidate if:

- It's disorganized and cluttered.

- It's a bottleneck that causes other areas to fall behind.

- It has a high error rate (final products frequently contain errors).

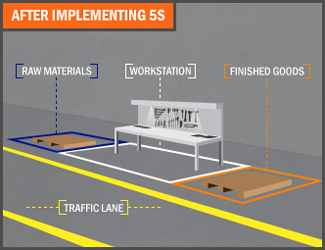

Once you have selected an area, get a better understanding of how work is done. This might include creating a map of the current organization and workflow. Once the area is mapped out, use a pedometer to measure how much workers move when completing tasks and a stopwatch to time how long each task takes from start to finish.

Next, look at how workflow can be improved. Identify items and workstations that can be rearranged to reduce the amount of movement required to complete tasks. It is also important to identify items or tools that may be missing from the area. Make these easy to find and access to eliminate the time workers waste searching for the tools they need to complete their tasks.

After you have identified what needs to be in the space and how it might be better organized, map out how it should be, and reorganize it using 5Ss. Once fully implemented, track the improvements. You should see a significant improvement in efficiency.

Making Your Continuous Improvement Program Last

The important thing is to make sure you implement 5S in every part of your business. As your program progresses, other ideas for improvements will become apparent. For example, an improvement in shipping may make issues in procurement, fabrication, and assembly more obvious-enabling workers to address problems they were unaware of.

As the name of the final step in 5S (Sustain) suggests, 5S is meant to be practiced every day, in every part of the workplace. This makes continuous improvement possible. When a change occurs, workplace organization and the tools used can be updated. New standards are created, adapted to each new process.

Continuous Improvement Tools

Having the right tools for your continuous improvement plan will make the process easier. No matter if you need to create 5S labels for supplies, operation instructions to streamline tasks, or quality control labels to help improve quality, DuraLabel industrial label and sign printers and supplies by Duralabel make it possible.

Take your workplace organization a step further with PathFinder floor marking and wayfinding supplies. With a variety of available colors, you can color code tools, supplies, pathways, and much more to keep your workplace running efficiently. Our free 5s System Best Practices Guide helps you identify and define areas of improvement within your facility. Download your copy below.

Related Resources

Calculating Overall Equipment Effectiveness (OEE)

What Is Overall Equipment Effectiveness and How Is It Calculated? Overall Equipment Effectiveness (OEE) is a ...

Read

Value Stream Mapping in Lean Manufacturing

What is Value Stream Mapping? Value stream mapping is a lean manufacturing technique that follows the ...

Read

Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter? Lean manufacturing principlesare core ...

Read.png)