Value Stream Mapping in Lean Manufacturing

What is Value Stream Mapping?

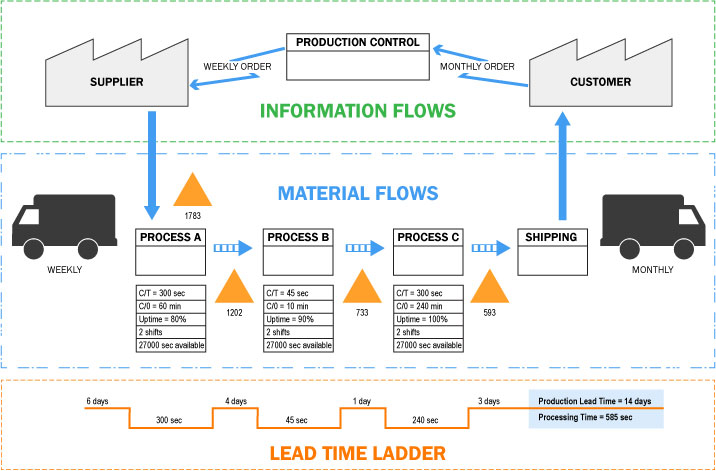

Value stream mapping is a lean manufacturing technique that follows the production journey of a product from the supplier until it's in the arms of the customer. A value stream map takes the form of a flow diagram by using three types of VSM icons that flow from left to right to document each step in the production process: material flow, information flow, and general icons. For each step, you can jot down details describing the behavior of that particular step. Arrows or dividing lines between each step are drawn at points where the product is handed off from one place to another or where a product is waiting for the next step.![]()

Using a flow diagram helps to analyze the steps of the production process to reveal areas of waste and makes it easier to visually pinpoint inefficiencies, such as bottlenecks that keep work from moving through the system. There are two separate aspects of value stream mapping that work together to help pave the way towards improvement: current state and future state maps.

The first step of value stream mapping is to create a current state map. This map identifies the current processes and flow of materials and information, and will often show the differences between how things are done in reality and the documented processes and procedures. This flow diagram helps to spot areas of non-value adding activities, or wasted time, such as delays, restrictions, and excess inventories, including the average time of the completion from one step to the next. Once this map is complete, you can prioritize the problem areas for improvement.

The goal of the future state map is to eliminate the waste found in the current state map. To do this, management must apply house of lean principles and lean thinking to identify improvements to make to the value stream that will create a shorter lead time.

The current and future value stream maps need someone responsible for their implementation to ensure improvements come to fruition. Often, larger organizations will consult a lean advisor to work with current management to help carry out the implementation of these maps in a methodical way. Each organization's value stream map will look a little different based on your own unique processes.

Benefits of VSM

Regardless of your industry or business, you can experience benefits of value stream mapping in any work that has repeatable processes. Some benefits include:

- It can be applied in a variety of industries such as healthcare, service industry, IT, auto, and more

- It's easy to understand and convey to anyone using a visual flow diagram

- The map provides a common language to be used when talking about processes

- Improves communication throughout departments due to a higher level of discussion about specific processes

- Helps to produce an overall higher-quality product due to a deeper understanding of what the customer wants and when they want it

VSM is an effective tool for improving communication processes across all business functions, especially in manufacturing and production lines.

Examples of VSM in Action

Dalco Metals, Inc

John Ring, Executive Vice President of Dalco Metals, Inc. gives credit to their long-term success of attention to quality and their focus on customer's needs from the implementation of value stream mapping. The front office employees of Dalco Metals took action by using value stream mapping to discover that it took longer to process the paperwork for an order than it took to manufacture the order itself.

To fix this, the company redesigned their office space to group the staff around the flow of the work, rather than in departments. This change to their space, along with other streamlining methods, "cut the processing time from four days to two," said Ring. The company has gone on to continue to apply lean processes to their manufacturing floor.

(Source: Wisconsin Manufacturing Extension Partnership, 2015. Success Story: Dalco Metals Gets Leaner with 5S. 1-2.)

Lockheed Martin Aeronautics & Northrop Grumman Electric Systems

These two companies work together on important defense-related contracts. Lockheed Martin Aeronautics (Ft. Worth, TX) builds military fighter aircrafts. Northrop Grumman Electronic Systems (Baltimore, MD) supplies sophisticated radars and electronics for Lockheed Martin airplanes. Both companies have the same goal to implement innovative ways to reduce costs while adding value to their products. Other small companies also contribute to the overall product.

The two companies assigned "lean advocates" to help them form a shared value stream map. The map helped the two companies visualize information and material flow from Lockheed Martin to the second tier suppliers, documenting the flow of inter-company information from the shop floors to office activities. They defined their current and future state value stream maps together, with the goal to create additional value for their companies all the way down to their suppliers.

To do this, the companies began to share a common vocabulary and understanding of lean manufacturing practices, and committed to inter-organizational goals instead of a solely internal focus within each company. The result of these necessary changes was improved overall efficiency between the organizations, which in turn delivered a greater value to their customers.

Since the shared value stream map was implemented, the companies have conducted multiple value stream mapping events. 19 improvement opportunities have been identified and solved, and lead times have been reduced by over 40%. The success of their VSM efforts was due to effective leadership, support, and buy-in, open and honest communication, and educated outside facilitation which was essential to help coordinate the various steps in the process.

(Source: Lean Advisors, 2017. Macro Value Stream Mapping at Northrop Grumman and Lockheed Martin.)

By implementing value stream mapping, you open up the opportunity to sustain continuous improvement facility-wide. Management must commit to continuously monitor and assess the production process going forward to ensure continuous improvement; this is where methods of lean come into play to help streamline processes including Kanban, Six Sigma, 5S, and more. Discover how you can use lean tools like 5S to streamline your value stream mapping with the Best Practice Guide. Improve efficiency, quality, and overall value of your product and production process.

Take Action Today

Want to learn how to apply value stream mapping in your facility? Call us today at 1-888-788-9936. One of our experts will help you integrate value stream mapping into your workflow using proven Lean strategies and DuraLabel industrial labeling tools.

Related Resources

Related Resources

Lean Manufacturing Principles and The 5S System

What Are Lean Manufacturing Principles and Why Do They Matter? Lean manufacturing principlesare core ...

Read

TPM Implementation

TPM Implementation Total Productive Maintenance (TPM) is a continuous improvement program that focuses on ...

Read

Continuous Improvement Ideas for the Workplace

Success in today's competitive market requires constant innovation and a vision focused on continuous ...

Read.png)