Hazard Communication Solutions for a Safer Workplace

A faded label. A missing hazard symbol. An outdated SDS. These small details can trigger big problems in facilities that handle chemicals daily. Hazard communication (HazCom) is about more than compliance—it's about preventing confusion before it becomes a safety risk.

Clear hazard communication allows workers to quickly recognize chemical risks, understand how to handle materials safely, and respond appropriately in an emergency. Without accurate labels or accessible hazard information, even routine tasks can lead to exposure, injury, and costly downtime.

A well-structured HazCom program ensures workers know exactly what they’ are handling, how to stay safe, and what to do if something goes wrong. This article explores how to strengthen your hazard communication system, improve chemical labeling practices, and align with the OSHA HazCom standard using practical tools and scalable strategies.

Requirements of the OSHA HazCom Program

The OSHA HazCom standard is built around five key components that every employer must implement:

- A written hazard communication plan

- An up-to-date inventory of hazardous chemicals

- Clear and accurate container labeling

- Accessible safety data sheets (SDSs) for every chemical

- Ongoing employee training

These elements create a closed-loop system: identifying a chemical, labeling it, storing its SDS, and training workers to handle it safely. When one part breaks down—like a missing hazard label or an outdated SDSs—the whole system becomes unreliable.

HazCom violations ranked as OSHA’s second most cited standard in 2023, with more than 3,200 citations issued nationwide. Many of these citations stemmed from inconsistent or missing labels, outdated SDSs, or incomplete training programs.

Hazard Communication Labeling: The Front Line of Compliance

Labeling is one of the most visible and actionable elements of a hazard communication program. Every container, regardless of size or use, must clearly communicate the chemical’s identity and associated hazards.

Under the OSHA HazCom standard, compliant labels must include:

- Product identifier

- Signal word (e.g., “Danger” or “Warning”)

- Hazard and precautionary statements

- Globally Harmonized System (GHS) pictograms

- Supplier information

These requirements are not optional. They are foundational. Yet in many facilities, labels are still being handwritten, copied from old spreadsheets, or pulled from outdated templates. Each of these methods increases the risk of error and non-compliance.

As the number of chemicals in circulation grows, managing labels manually becomes slow, inconsistent, and risky. This is where dedicated industrial labeling software becomes a valuable asset—especially when it integrates safety data, supports GHS formats, and eliminates repetitive rework.

LabelForge PRO in Action: Smarter Chemical Labeling

Managing hundreds of chemicals across departments is a common challenge in industrial facilities. Without a centralized system, supervisors must track down SDS data, update spreadsheets, and manually format each label. It’s time-consuming, and one formatting mistake could result in a costly OSHA fine or, worse, a workplace injury.

Outsourcing chemical labels can also lead to costly delays, unexpected downtime, and increased safety risks. For greater speed, flexibility, and accuracy, facilities need the ability to create compliant labels in-house.

With DuraLabel’s free LabelForge PRO:

- SDS data can be pulled directly into the labeling interface

- GHS formats are automatically applied using prebuilt label templates

- Labels are printed on demand using a DuraLabel Industrial Sign and Label System

- Updates are instantly reflected across your label system

This kind of streamlined workflow reduces compliance risks, prevents human error, and frees up valuable Environmental, Health, and Safety (EHS) team hours.

Safety Data Sheet Integration for Chemical Label Accuracy

Every chemical in your workplace should have an up-to-date safety data sheet outlining its hazards, handling procedures, and first-aid measures. But when your SDS library lives in one system and your labeling process in another, that disconnect introduces a compliance risk.

Integrated systems close that gap. By pulling SDS data directly into label creation, teams work faster and more accurately. Labels are populated with current hazard statements and pictograms pulled directly from current SDS files, reducing the chance of human error and ensuring regulatory alignment.

This approach also simplifies audits. When inspectors ask to verify that a label matches an SDS, you have a streamlined record trail that’s easier to access and defend.

Industrial Label Templates That Drive Efficiency

Preformatted label templates tailored for industrial use help teams produce compliant labels at scale. When aligned with GHS compliance standards, these templates eliminate guesswork and ensure consistency across a variety of container types.

For example, a maintenance crew labeling secondary containers for cleaning solvents could use templates that standardize hazard information while also including internal tracking data. The result: uniform, compliant labeling with minimal manual formatting.

A strong template system supports:

- Multiple label sizes for different container types

- Variable data fields for unique batch numbers or expiration dates

- Easy reprinting when chemicals are moved, transferred, or renamed

Preformatted label templates tailored for industrial use help teams produce compliant labels at scale. When aligned with GHS compliance standards, these templates eliminate guesswork and ensure consistency across a variety of container types.

For example, a maintenance crew labeling secondary containers for cleaning solvents could use templates that standardize hazard information while also including internal tracking data. The result: uniform, compliant labeling with minimal manual formatting.

A strong template system supports:

- Multiple label sizes for different container types

- Variable data fields for unique batch numbers or expiration dates

- Easy reprinting when chemicals are moved, transferred, or renamed

Why Chemical Identification Labels Matter in Workplace Safety

In one documented case at a research laboratory, an unlabeled bottle containing 30% hydrogen peroxide was mistaken for water. The chemical was used to dilute formamide, triggering a violent reaction that shattered the container and exposed the researcher to hazardous materials. Emergency medical care was required on site. Investigators traced the incident to a single point of failure: the lack of a label on a secondary container.

This incident underscores the real-world importance of consistent, compliant labeling. A clear label can prevent a serious mistake before it starts.

Smarter Systems, Safer Outcomes

Managing labels across dozens, or even hundreds, of chemicals can quickly become unmanageable without the right tools. While some teams still rely on spreadsheets and manual entry, others are turning to industrial labeling systems to automate and streamline their HazCom processes.

Software solutions with built-in SDS integration and GHS-compliant templates, and centralized printing capabilities help cut down on administrative work and minimize errors. By automating key parts of the labeling process, teams can improve consistency, reduce rework, and maintain compliance more effectively.

DuraLabel Resources to Strengthen Your HazCom Program

A strong hazard communication system starts with clear, compliant labels and the flexibility to adapt as your chemical inventory evolves.

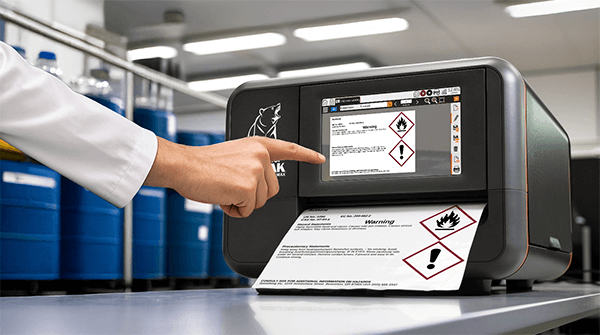

DuraLabel offers a complete solution with the DuraLabel Kodiak Max HazCom/GHS Kit. Built for industrial environments, this all-in-one system combines high-performance label printing with tools specifically designed for chemical labeling compliance. The kit includes preloaded label templates, integrated GHS pictograms, and durable supplies suitable for secondary containers, drums, and facility signage.

Paired with pre-installed LabelForge PRO software, the kit enables fast, standardized label creation with real-time safety data sheet integration. That means fewer compliance gaps, easier updates, and improved chemical safety across departments.

Whether you're labeling large storage drums, small squeeze bottles, or GHS-aligned signage for loading docks, DuraLabel makes it easy to print exactly what you need—when you need it.

To explore how DuraLabel can help you build a safer, more compliant chemical labeling process, contact a DuraLabel representative at 1-888-788-9936. You can also download the free GHS/HazCom Labeling Quick Start Guide for practical tips on improving your HazCom program from the ground up.

Read Next:

HazCom Basics: Chemical Labeling 101

How Chemtrade Logistics Optimized Labeling for Compliance and Safety

.png)