Electrical Panel Compliance Made Clear with Floor Marking

Electrical panels are an integral part of large and small facilities throughout the United States. The panels control the energy that keeps machines operating, lights buzzing, and computers running, yet they are easy to ignore during the day-to-day routine. The National Institutes of Health (NIH) found these shocking numbers related to electrical hazards:

- 400 high-voltage electrical injuries per year

- 30,000 non-fatal shock incidents per year

- 1,000 deaths per year

It's important to know OSHA electrical panel clearance requirements for maintaining clear, safe areas around electrical panels and how to communicate those boundaries best with effective floor marking.

What are the OSHA Regulations for Electrical Panel Clearance?

OSHA electrical panel clearance requirements (29 CFR 1910.303) includes a section for establishing and maintaining space around electrical panels and other systems that require servicing, adjustments, or maintenance while energized.

These clearance rules aren’t just for large-scale industrial settings. Facilities of all sizes must provide safe, unobstructed access to electrical equipment—especially during maintenance or emergencies. Without clearly defined boundaries, workers may accidentally place items or walkways too close to energized panels, increasing the risk of shock, arc flash, or fire.

OSHA citations for electrical violations can be found across a variety of industries, and failure to follow clearance requirements can lead to costly fines and serious injuries. Applying consistent visual cues like floor marking tape can help reinforce safety zones and make compliance part of the daily workflow—not just a checkbox.

Here's a broad breakdown of electrical panel clearance space requirements when planning around electrical panels:

- Sufficient access and working space must be provided, and properly marked, around an electrical panel to meet floor marking standards

- The width of the space in front of an electrical panel must be the width of the equipment or 30 inches, whichever is wider

- The working space must allow for a hinged panel or equipment door to open at a 90 degree angle

- The vertical space must extend from the grade, floor, or platform immediately in front of the electrical panel to either:

- 6 feet, 3 inches above the ground (for buildings or areas constructed before August 13, 2007)

- 6 1/2 feet above the ground (for buildings constructed after August 13, 2007)

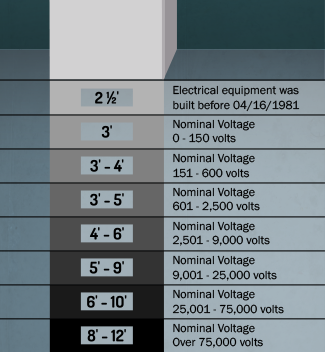

- The clear working space — shown with floor marking tape — in front of an electrical panel (or piece of electrical equipment) must be:

- 2 1/2 feet if the electrical equipment was built before April 16, 1981

- 3 feet when the nominal voltage is between 0 and 150 volts

- 3 to 4 feet when the nominal voltage is between 151 and 600 volts

- 3 to 5 feet when the nominal voltage is between 601 and 2,500 volts

- 4 to 6 feet when the nominal voltage is between 2,501 and 9,000 volts

- 5 to 9 feet when the nominal voltage is between 9,001 and 25,000 volts

- 6 to 10 feet when the nominal voltage is between 25,001 and 75,000 volts

- 8 to 12 feet when the nominal voltage is over 75,000 volts

Note: The exact working space measurements depend on voltage, insulation, and exposed live and ground parts that may be present. Consult Table S-1 and S-2 in 29 CFR 1910.303 for more detailed guidance on boundary measurements. These boundaries can be properly marked with the right floor marking tape.

OSHA lists specific requirements for switchboards, panelboards, and distribution boards that control a building's light and power circuits. Those installations must follow these requirements:

- The vertical space must extend from the grade, floor, or platform immediately in front of the electrical panel to a structural ceiling or 6 feet, whichever is lower

- The space equal to the width and depth of the equipment must be kept clear, unless it's used to protect against condensation, leaks, sprinklers, and other damage

It's best to use hazard floor marking tape to properly set boundaries to meet these requirements.

Additional Tips for Electrical Panel Compliance

OSHA electrical panel clearance maintains a few rules when pipes, ducts, and other equipment may be present near electrical panels. Those rules include the following:

- The area of the electrical equipment should be kept clear of any other material, equipment, piping, or ducting systems

- This clear space should include the entire footprint of the equipment, and extend upwards to six feet above the top of the equipment (or to the structural ceiling, if that is lower)

- Pipes, ducts, and other equipment may not be located in this "headroom" space unless there is effective physical protection in place, including drip-proofing or leak-proofing

How to Communicate Boundaries with Floor Marking

Once you've established boundaries around an electrical panel, it's time to consider how to best communicate those borders. OSHA offers no requirements for specific floor marking colors or requirements, but some best practices can guide your decision-making process.

Here's how floor marking tape can make those borders clear and keep workers safe:

- Striped hazard floor marking tape: The bright colors and stark contrast of striped hazard tape make it easy to see from a distance. Most facilities use red-and-white striped tape or black-and-yellow striped tape for outlining clearance areas around electrical equipment

- Solid color floor marking: Solid floor marking tape can denote areas when striped floor marking is used elsewhere as part of a wider color-coded system; yellow floor marking typically signals caution and indicates pedestrian paths and work areas, while white tape is most often used for general purposes

- Floor signs: Use large, durable floor signs to alert workers to electrical panels, and remind them to keep the area clear; this can clarify and reinforce the messages communicated with floor marking tape

Floor Marking Resources from DuraLabel

Marking electrical panel clearance zones doesn’t have to be complicated. With the right tools, you can meet OSHA standards, improve visual communication, and maintain a safer workspace—all in a few simple steps.

DuraLabel’s floor marking solutions are built for durability in demanding environments, from manufacturing floors to electrical rooms. Use striped hazard tape to signal restricted access, solid color tape to support your facility’s color-coded system, and bold floor signs to reinforce critical safety messages. Every option is designed to help you comply with 29 CFR 1910.303 while saving time and reducing confusion.

Need help getting started? Download the free Floor Marking Quick Start Guide for quick, practical tips—or give us a call at 1-888-411-3520 to speak with a DuraLabel expert about your facility’s needs.

Read Next:

Related Resources

Inside the Changes to NFPA 70 Electrical Labeling

What Changed in NFPA 70 Electrical Labeling in 2026? In the current edition of the National Fire Protection ...

Read

The Importance of Electrical Labeling for Electrical Installations

Why Is Electrical Labeling Important for Electrical Installations? Electrical installations require more than ...

Read

Solar Panel Safety Starts with the Right Labels

What Safety Labels Are Required for Solar Panel Installations? Solar panel safety depends on clear labels ...

Read.png)

.webp)