Strengthen Electrical Safety Through Effective Arc Flash Training

Electrical switchgear lineup covered with arc-flash DANGER and WARNING labels, supporting effective arc flash training, PPE compliance, and NFPA 70E electrical safety awareness.

What Electrical Safety Hazards Put Workers at Risk?

Electricity powers the modern workplace. Motors, ovens, presses, and mills all rely on electrical systems, and many facilities use high voltages and currents to achieve their goals. But accidents and equipment failures in these high-powered systems can be deadly. Electric shock, burns, and arc flash hazards remain serious threats that must be addressed through consistent arc flash training and safety programs.

Understanding where these hazards originate is the first step toward prevention.

High Power, High Danger: Understand Arc Flash Hazards

Exposure to strong electrical current can kill an affected person; strictly speaking, that's when an electric shock becomes "electrocution." Usually, death is the result of neurological damage or muscular interference, such as heart attacks. Strong current flowing through a body will generate enough heat to cook living tissue, so even electrical injuries that don't kill immediately can still cause severe burns that lead to death.

Another threat is the risk of arc flash hazard. Arc flashes are essentially electrical explosions; they begin with a small spark that becomes a runaway arc, drawing more and more power until it destroys the conductors around it or the power is cut off. The result is a burst of intense light and extreme heat, taking a fraction of a second to reach thousands of degrees. Even if workers have no contact with equipment or conductors, they can be killed or maimed by the blast from an arc flash.

Even Low Voltages can be Dangerous

It's easy to focus on high voltages when it comes to the hazards of electric shock and arc flash. Those hazards don't disappear at low voltages, though. A 2008 medical study of non-lethal, low-voltage injuries found that even these "safe" situations can be very serious.

After two months of recovery time, only one-third of the patients in the study had been able to successfully return to work. Even then, long-term effects included numbness, paresthesia ("pins and needles"), and chronic pain. Ongoing neurological effects included problems with memory, attention, and behavior, even including violent tendencies among victims who had no prior history of behavioral trouble.

What's Causing These Arc Flash Incidents?

Many electrical accidents share the same preventable causes: poor maintenance, missing procedures, or inadequate training. According to the National Institute of Occupational Safety and Health (NIOSH), more than a third of electrocution incidents occurred in workplaces with no safety program or written procedures in place.

In most electrical injury cases, at least one of the following breakdowns was present:

| Breakdown Area | What Went Wrong |

|---|---|

| Safe Work Procedures | Not implemented or not followed |

| Personal Protective Equipment (PPE) | Not provided or not worn |

| Lockout/Tagout (LO/TO) | Not implemented or ignored |

| Regulatory Compliance | OSHA, NEC, or NESC requirements not followed |

| Safety Training | Inadequate or missing |

These gaps demonstrate why safety must be intentional, not assumed.

Electrical Safety and Arc Flash Training Requirements

The need for structured training isn’t new. The Occupational Heath and Safety (OSHA) regulations in 29 CFR 1910.332 require electrical safety training for any employees who "may reasonably be expected to face? risk of injury due to electric shock or other electrical hazards." OSHA has compiled a list of job titles that typically include this kind of risk:

- Blue collar supervisors

- Electrical and electronic engineers

- Electrical and electronic equipment assemblers

- Electrical and electronic technicians

- Electricians

- Industrial machine operators

- Material handling equipment operators

- Mechanics and repairers

- Painters

- Riggers and roustabouts

- Stationary engineers

- Welders

OSHA distinguishes between qualified and unqualified workers. Qualified employees receive advanced electrical safety instruction, while unqualified workers learn how to recognize hazards and maintain distance from them. Both are vital for maintaining arc flash safety in the workplace.

Who Needs Electrical and Arc Flash Safety Training?

OSHA considers any workers who will work on or near exposed energized parts to be "qualified workers," and those individuals need specialized training to help prevent electric shock. Other workers are considered "unqualified workers," and primarily need to be trained to recognize hazardous situations and keep away from them. Qualified workers must to be trained to deal with those situations safely, as part of their duties. Examples of these different types of training can be found in 29 CFR 1910.333(c)(3)(i) and (ii).

This distinction between qualified and unqualified workers represents broad categories, rather than an "A or B" choice between two defined options. Under the OSHA rules, the degree of training provided for a worker must be appropriate for that worker's level of risk. In fact, OSHA provided a letter of interpretation to clarify that even non-electrical workers may need electrical safety training, if they will be exposed to an electrical hazard.

As a result, employers need to assess the risk that each worker may be exposed to, and will be held responsible for providing the appropriate training. How can employers know what OSHA will consider "appropriate"?

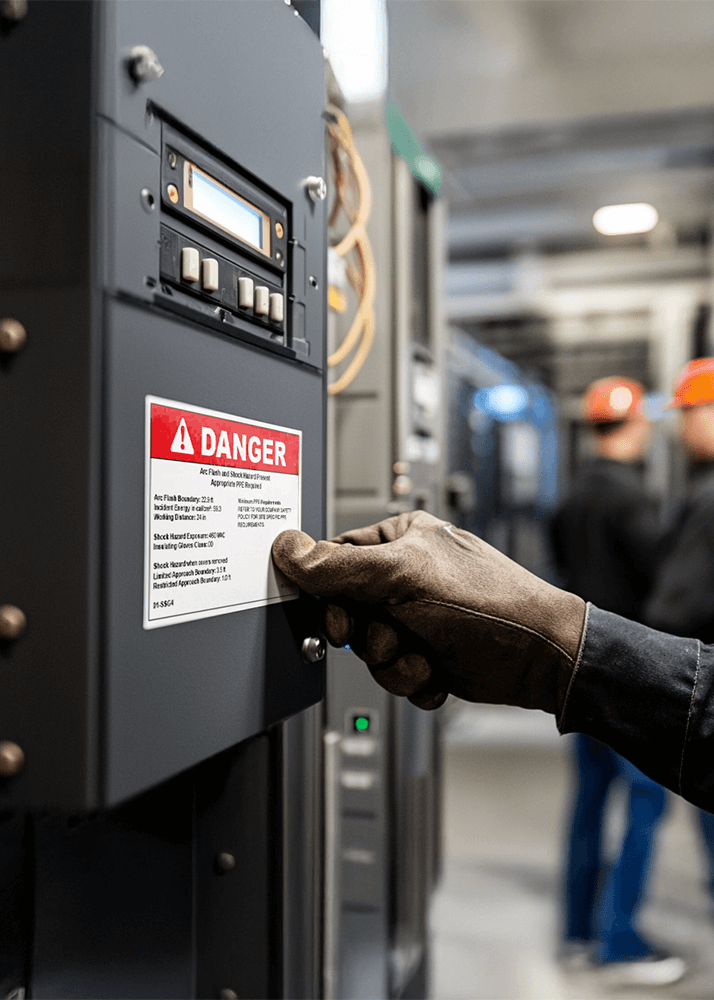

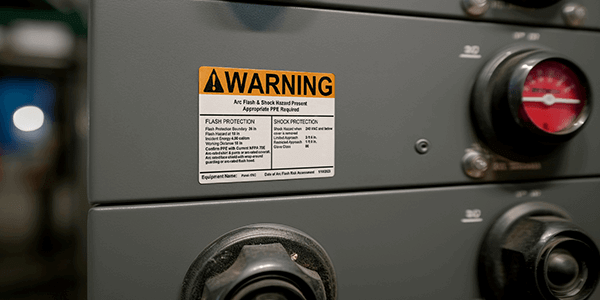

A gloved hand applies an Arc Flash Danger label to an electrical control panel in an industrial facility in compliance with NFPA Arc Flash Requirements.

NFPA 70E Arc Flash Training Requirements?

The National Fire Protection Association (NFPA) makes recommendations on safe electrical work practices, and writes those recommendations into the well-respected NFPA 70E standard. Because NFPA 70E is compiled and used by experts in the field, OSHA frequently refers to it as an indicator of accepted practices in the field of workplace electrical safety. As a result, following NFPA 70E is an excellent approach for satisfying OSHA's electrical safety requirements.

NFPA 70E describes its general training requirements in Article 110.2. The requirements there are divided into two broad categories:

- Emergency Response Training. This includes basic shock response training as a requirement for all workers exposed to shock hazards. More in-depth training is required for workers who are designated as responders for medical emergencies. This training category requires refresher training at least once per year.

- Employee Training. This category covers OSHA-style worker training, similarly separated into sections for qualified and unqualified persons. The NFPA offers more detailed training requirements for qualified workers. Training in this category must be refreshed at least once every three years.

These guidelines ensure all personnel understand electrical hazards and can respond safely in high-risk situations.

The NFPA Gets More Specific

Within the Employee Training category, the NFPA's distinctions between qualified and unqualified workers is much like OSHA's definitions for those groups. However, the NFPA standard's definitions in Article 100 include a more specific requirement for a worker to be considered qualified. A qualified person must have demonstrated skills and knowledge relevant to their work, and must have received specific safety training to identify and avoid the hazards that may be present. This means that NFPA 70E requires specific safety training as a prerequisite for being allowed to work on or near exposed energized parts.

Additionally, with the variety of electrical equipment and maintenance tasks that may be called for, the NFPA points out that a worker may be qualified for one task, but unqualified for another. To account for this, all training and assignments are treated in the standard as being specific to a given task. In fact, where a task is rare or unusual (something performed less often than once per year), the affected employees need to have retraining for that specific task each time the work is to be done.

Workers are not responsible for acquiring the appropriate training on their own; instead, employers are responsible for providing all of the training discussed in NFPA 70E. Employees are responsible for following the practices they've been trained on.

Electrically Safe Conditions and the Arc Flash Boundary

The most basic element of electrical safety training is what the NFPA calls "Establishing an Electrically Safe Work Condition." In a survey of arc flash injury victims, 94% of those interviewed believed that the incident could have been prevented, and the most frequently-mentioned method of prevention was simply to "turn the power off."

(Source: Kowalski-Trakofler K, Barrett E, 2007. "Reducing Non-Contact Electrical Arc Injuries: An Investigation of Behavioral and Organizational Issues," Journal of Safety Research, 38(5):597-608.)

Essentially, that's what the NFPA is promoting: turning off the power. There are six steps to establishing an electrically safe condition, described in Article 120 of NFPA 70E:

- Identify all possible sources of power to the equipment.

- Use appropriate steps to shut down the power, and then systematically disconnect each power source from the equipment.

- Where possible, verify (visually) that all disconnections are complete.

- Lock or tag out the power sources to prevent accidental re-energizing.

- Use an adequate test instrument to confirm that each part of the equipment has been effectively de-energized, and then verify that the test instrument is working normally.

- Where voltage may be induced, or where the de-energized parts could contact other energized parts, apply a ground connecting device rated for the available fault current.

If this process seems familiar (especially step 4, with its locks and tags), it's because this is an electricity-specific approach to a broader industry practice: Lockout / Tagout, or LO/TO.

This infographic identifies trends in electrical injuries, and describes the most common causes of these accidents.

Live Work Concerns

Strengthening your arc flash training program starts with clear communication and compliance. Consistent labeling, education, and routine updates help ensure workers recognize hazards and respect arc flash boundaries in every environment.

DuraLabel supports these efforts with practical tools designed for durability and compliance. The DuraLabel® Toro® Max Industrial Sign and Label System produces high-quality arc flash warning labels and safety signage that meet NFPA 70E requirements.

To help you get started, download the Arc Flash Labeling Quick Start Guide. This free resource provides step-by-step instructions for labeling, PPE selection, and workplace hazard prevention. It’s an essential tool for reinforcing arc flash safety across your facility.

Get help crafting a system that will provide the safety communication you need. Call 1-888-411-3520 and one of our experts will guide you through the process.

Arc Flash Resources for Safer Workplaces

Preventing arc flash hazards starts with education and consistent training. A well-structured safety program—supported by clear labeling—ensures every worker understands their responsibilities and the limits of safe access.

DuraLabel provides tools that make arc flash safety practical and compliant. The DuraLabel® Toro® Max Industrial Sign and Label System allows teams to create durable arc flash warning labels that meet NFPA 70E standards and define arc flash boundaries throughout a facility.

For a deeper look into labeling and compliance, download the Arc Flash Labeling Quick Start Guide. This resource outlines labeling steps, PPE selection, and risk-assessment practices to strengthen your arc flash training and compliance efforts.

To streamline arc flash labeling across a site, contact a DuraLabel representative at 1-888-411-3520 and they will guide you through the process.

Related Resources

Arc Flash Protection Made Simple for Every Facility

What Is An Arc Flash Protection Boundary? An arc flash protection boundary defines the minimum safe distance ...

Read

How to Improve Arc Flash Hazard Safety in Mining Operations

How Can Mining Teams Reduce the Risk of Arc Flash Hazards? Mining operations depend heavily on electrically ...

Read

Arc Flash Safety in the Workplace: 5 Mistakes to Avoid

How Can Arc Flash Risks Be Identified? Arc flash risks can be identified by evaluating electrical systems, ...

Read.png)

.webp)